Electronic fuel oil optimizing processor for automobile

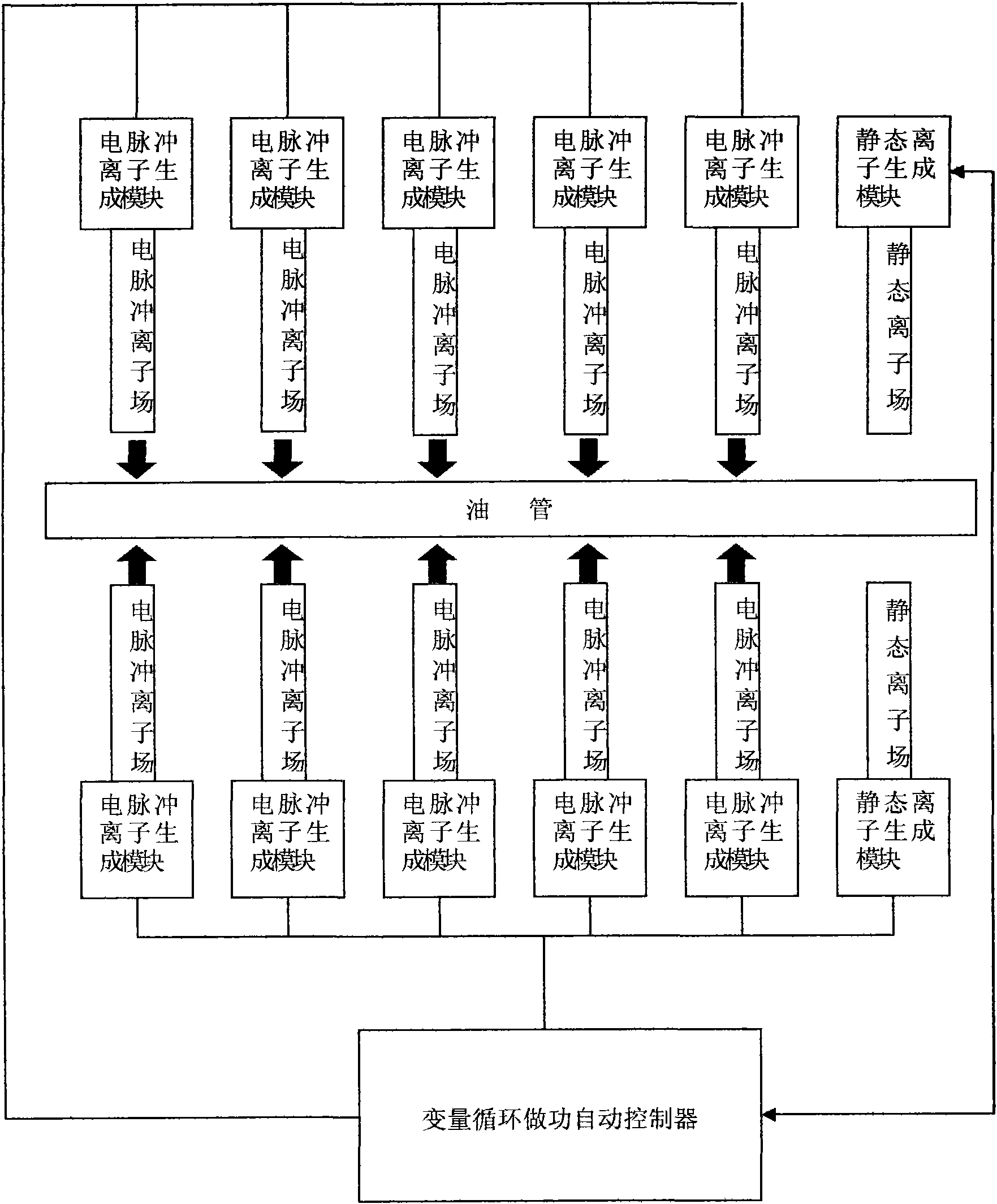

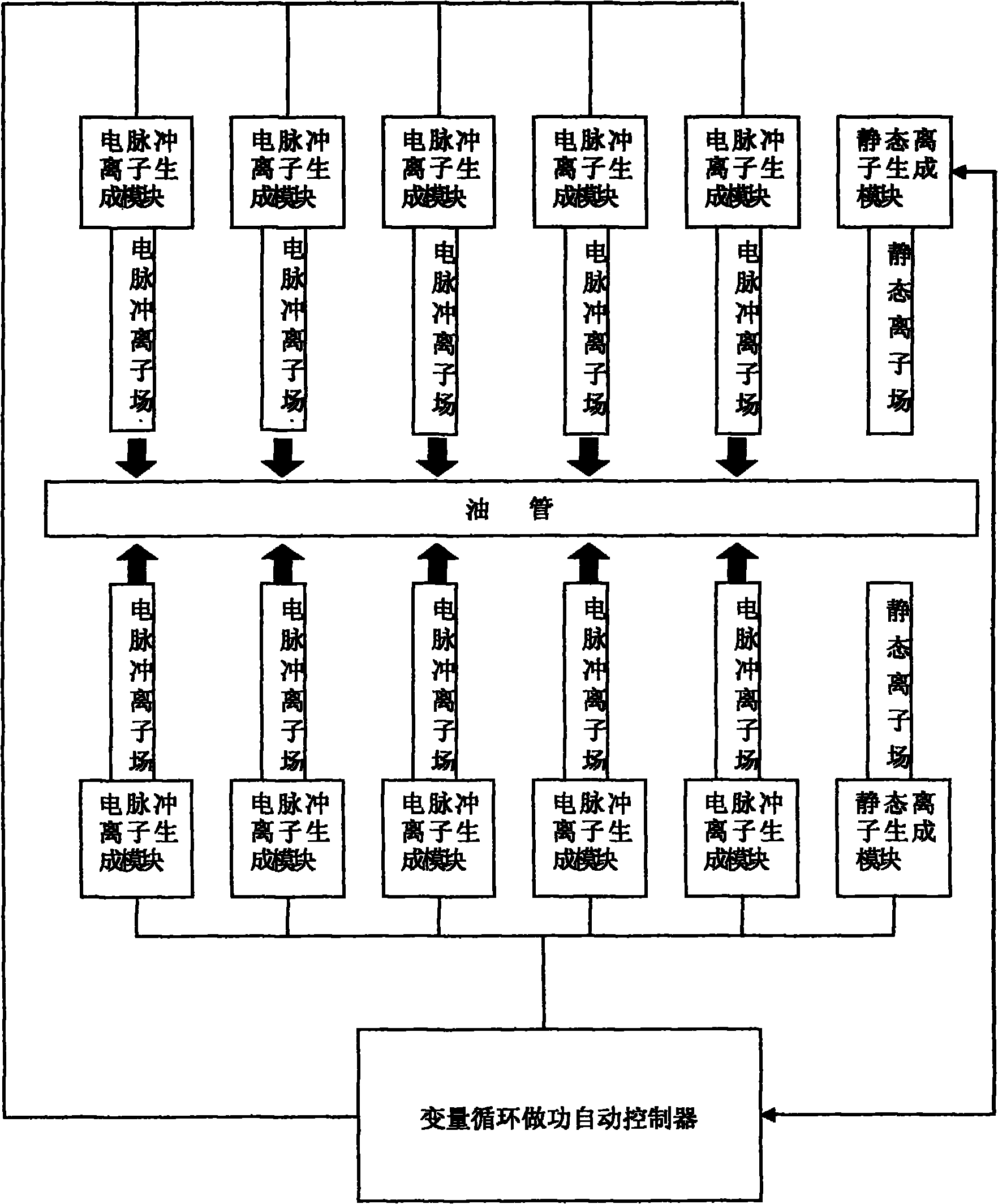

A processor and fuel technology, applied in combustion air/combustion-air treatment, machine/engine, engine components, etc., can solve the problems of unstable batch production quality, use effect, exhaust pollution, and reduce engine power, etc. The effect of prolonging efficient working period and service life, reducing exhaust pollutants and improving fuel burn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. Connect the "processor" in series between the gasoline vehicle engine common rail oil inlet connector (diesel vehicle is the high pressure oil pump inlet pipe connector) and the fuel filter at an appropriate place close to the engine and fix it securely;

[0032] 2. Use the 12 volt or 24 volt DC power supply for the car as the energy source of the "processor" electronic circuit, connect the "processor" power line to the circuit controlled by the car start switch, and the "processor" will start to work when the car starts, and the car will Turn off the "processor" to stop working and work synchronously with the engine;

[0033] 3. After power on, the "ion collision field and static stability field" in the "processor" will start to optimize the fuel processing, and the working indicator light on the shell will be on steadily, indicating that it is working normally. If there is a flashing light, it means that the contact is poor. You must immediately check the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com