Preparation method of anticlotting materials

An anticoagulant and anticoagulant technology, applied in the field of biomedical engineering materials, to achieve the effects of easy realization, excellent endothelial cell adhesion and proliferation, and definite anticoagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

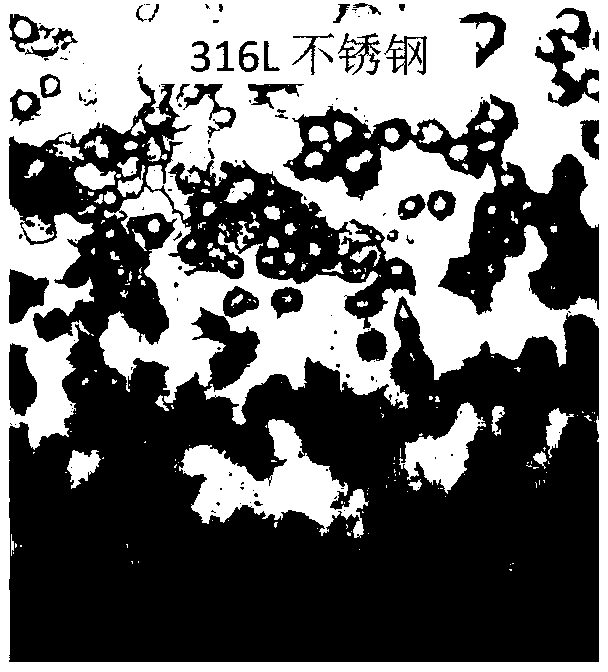

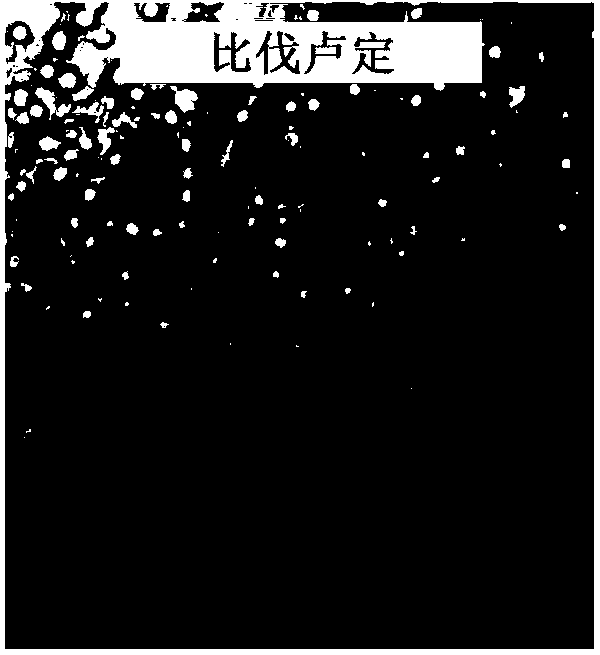

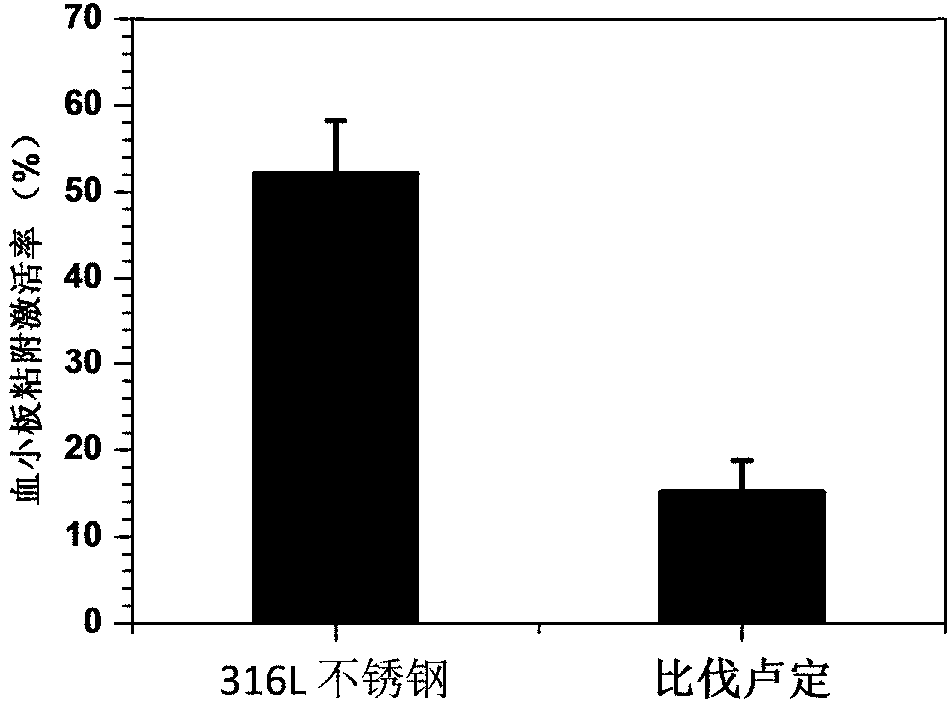

Image

Examples

Embodiment 1

[0016] Example 1 A preparation method of an anticoagulant material. The steps are:

[0017] Dissolve bivalirudin at 0.1 μg / ml in WSC solution, the composition of WSC solution is 9.76 mg / ml of 2-(N-morpholine) ethanesulfonic acid (MES) buffer solution, 1 mg / ml of 1-ethane 3-(3-dimethylaminopropyl) carbodiimide (EDC) and 0.24 mg / ml of N-hydroxysuccinamide (NHS). The 316L stainless steel with plasma polyallylamine coating was soaked in bivalirudin-WSC solution for 1 hour to react, then fully rinsed with PBS and distilled water with a pH value of 7.4, and dried.

Embodiment 2

[0018] Example 2 A preparation method of an anticoagulant material. The steps are:

[0019] Dissolve bivalirudin at 10 mg / ml in WSC solution, the composition of WSC solution is 9.76 mg / ml of 2-(N-morpholine) ethanesulfonic acid (MES) buffer solution, 1 mg / ml of 1-ethyl - 3-(3-dimethylaminopropyl) carbodiimide (EDC) and 0.24 mg / ml of N-hydroxysuccinamide (NHS). The 316L stainless steel coated with plasma polyallylamine was immersed in the bivalirudin-WSC solution for 48 hours to react, and then fully rinsed with PBS and distilled water with a pH value of 7.4, and dried to obtain the final product.

Embodiment 3

[0020] Embodiment 3 A preparation method of an anticoagulant material. The steps are:

[0021] Dissolve bivalirudin at 400 μg / ml in WSC solution, the composition of WSC solution is 9.76 mg / ml of 2-(N-morpholine) ethanesulfonic acid (MES) buffer solution, 1 mg / ml of 1-ethyl - 3-(3-dimethylaminopropyl) carbodiimide (EDC) and 0.24 mg / ml of N-hydroxysuccinamide (NHS). The 316L stainless steel coated with plasma polyallylamine was immersed in the bivalirudin-WSC solution for 24 hours to react, and then fully rinsed with PBS and distilled water with a pH value of 7.4, and dried to obtain the obtained product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com