Moving bed type thermal method distillation crystallizer

A distillation crystallization and moving bed technology, applied in the field of moving bed thermal distillation crystallizers, can solve the problems of high investment and operating costs, high operating costs, blockage of the evaporator structure, etc. Low cost, easy removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

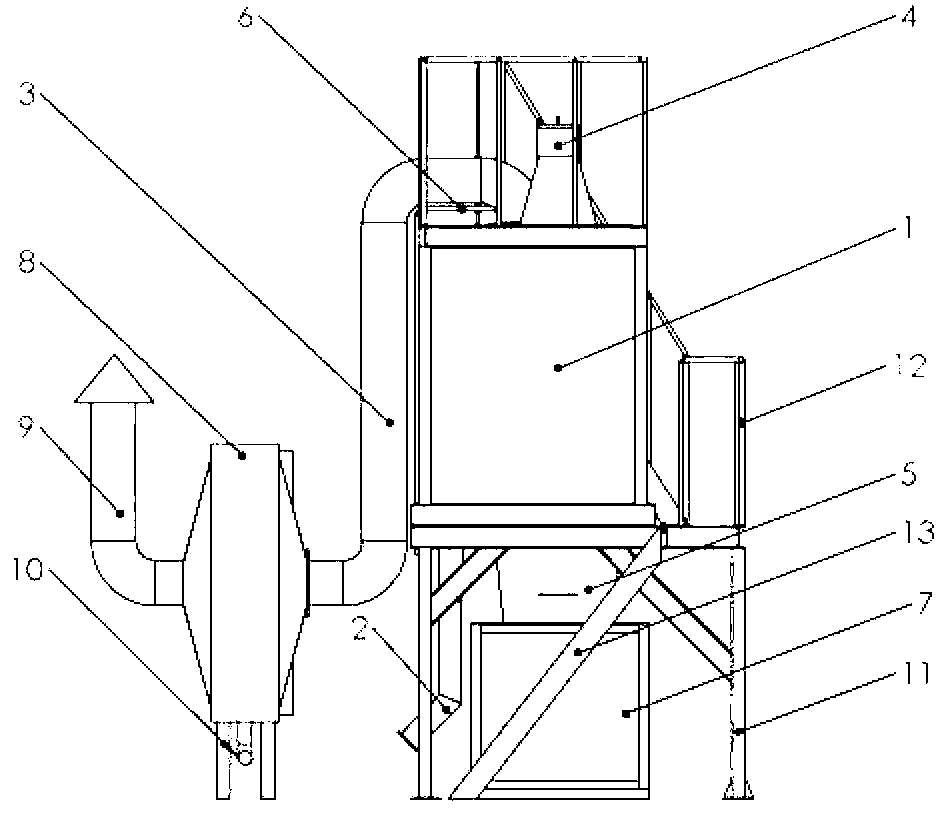

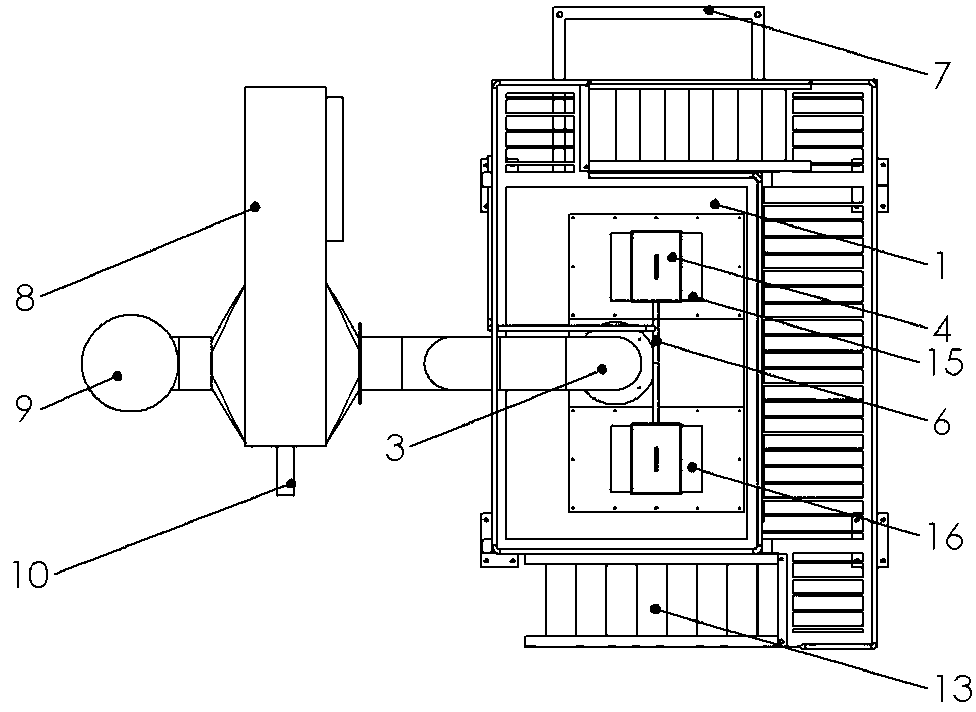

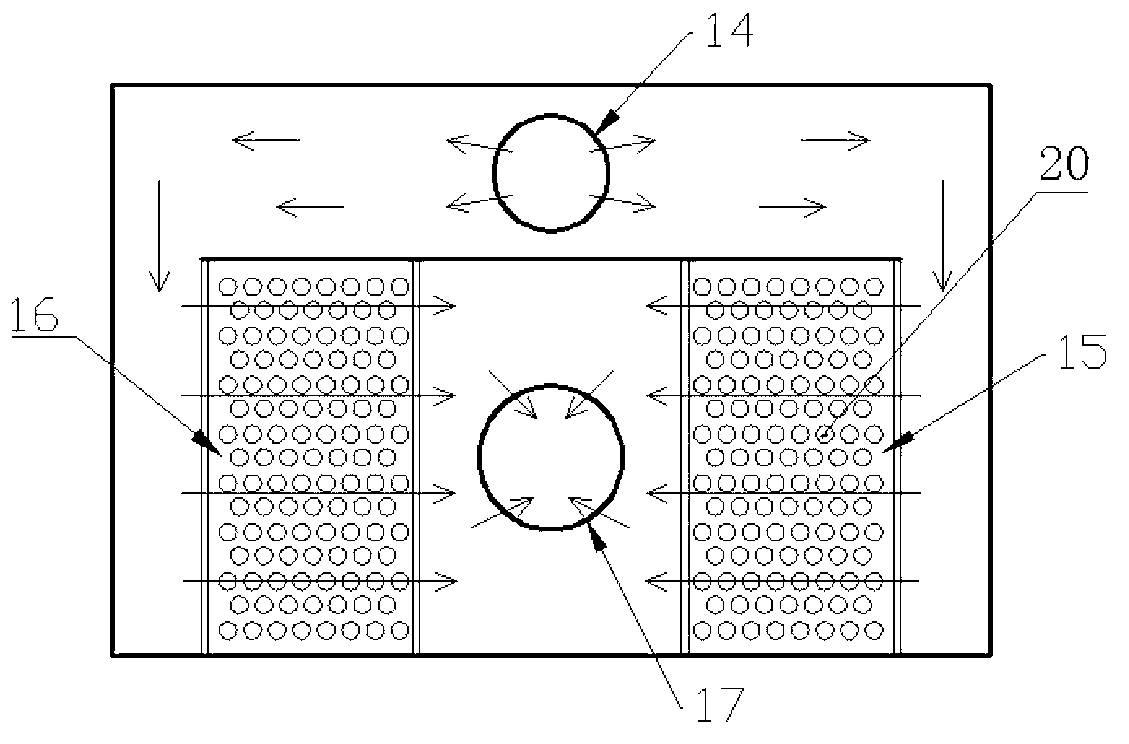

[0022] A moving bed type thermal distillation crystallizer provided by the present invention comprises a box body, an air intake pipe, a water injection pipe, an exhaust pipe and a condenser, the bottom of the box body is connected with the air intake pipe, the top of the box body is connected with the water injection pipe, and the box body The top is also connected to the exhaust pipe, and the other end of the exhaust pipe is connected to the condenser; there are multiple crystallization chambers in the box, multiple inlets on the top of the box, and multiple outlets on the bottom of the box. The top of each crystallization chamber is connected with each feed port, and the bottom of each crystallization chamber is connected with each discharge port.

[0023] Among them, according to actual needs, the box body can be equipped with 2-10 crystallization chambers and a corresponding number of inlets and outlets, and each crystallization chamber is filled with absorbent lightweight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com