Coating process for electrostatic spraying of polyether-ether-ketone powder on surfaces of drill collar threads

A thread surface, electrostatic spraying technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of shrinkage cavity, weak adhesion, and inability to withstand large torque, etc., to achieve The effects of strong adhesion, simplified structural design, and expanded design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

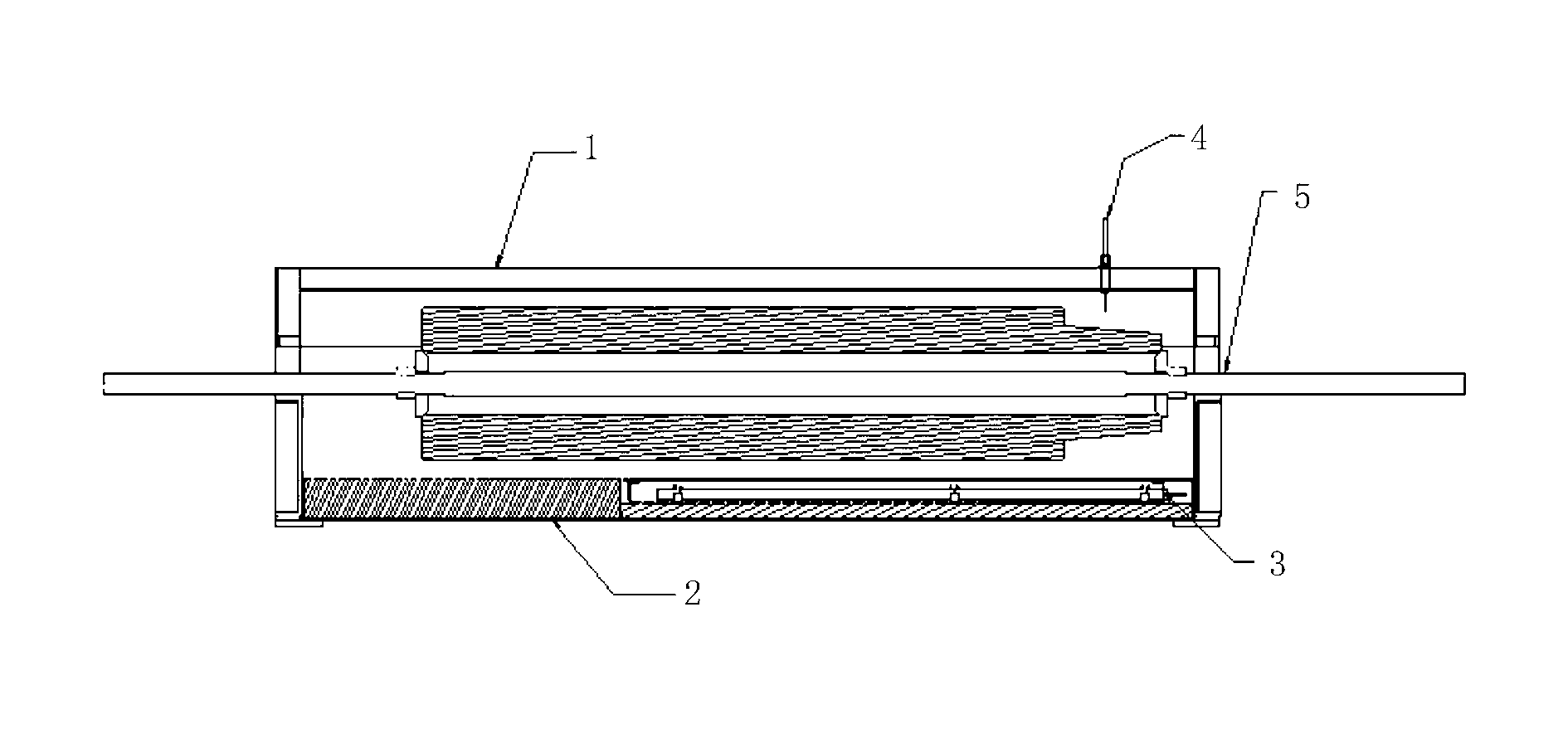

[0034] Embodiment 1: see brief figure 1 , the coating process of electrostatically spraying polyether ether ketone powder on the thread surface of the drill collar of the present invention, the operation process of spraying polyether ether ketone powder on the thread surface of the drill collar is as follows:

[0035] Step 1, first pre-treat the surface of the workpiece, including:

[0036] 1) Sandblasting treatment: use quartz sand to perform sandblasting treatment on the sprayed area of the workpiece, so that the surface roughness can reach Rz3.2-12.5μm;

[0037] 2) Spraying transition layer: thermal spraying nickel-aluminum alloy transition layer, the thickness of the transition layer is 0.05mm-0.15mm;

[0038] Step 2, workpiece installation and placement: place the workpiece in the spray heating incubator, put it into the bottom plate assembly, and connect the temperature control line;

[0039] Step 3, workpiece heating and temperature measurement, including:

[0040]...

Embodiment 2

[0049] Embodiment 2: This embodiment illustrates in more detail the process of spraying polyether ether ketone powder on the thread surface of the drill collar according to the present invention. The process flow includes: sandblasting—→ thermal spraying nickel-aluminum alloy transition layer—→ heating—→ Temperature measurement—→partial key heating—→temperature measurement—→electrostatic powder spraying—→insulation—→slow cooling.

[0050] Its specific implementation process:

[0051] A. Pretreatment of workpiece surface before spraying, including:

[0052] ⅰ. Sand blasting treatment. To protect the unsprayed surface of the workpiece, use quartz sand to blast the sprayed area of the workpiece to make the surface roughness reach Rz3.2-12.5μm. Compressed air is used to blow off sand adhered to the surface, and the roughness in the circumferential direction is required to be uniform.

[0053] ⅱ. Spray transition layer. The nickel-aluminum alloy transition layer is thermally sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com