Method for preparing copper sulfate in mode that stanniferous copper slag is leached in selective mode and free of evaporation

A selective, copper sulfate technology, applied in the direction of copper sulfate, process efficiency improvement, etc., can solve the problems of rising raw material cost, reducing copper recovery rate from purifying slag, large steam consumption, etc., achieving high comprehensive utilization of resources, steam The effect of high heat utilization rate and avoiding vicious circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

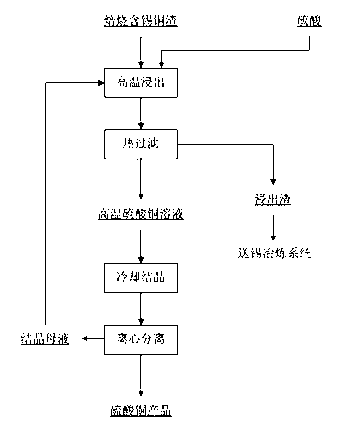

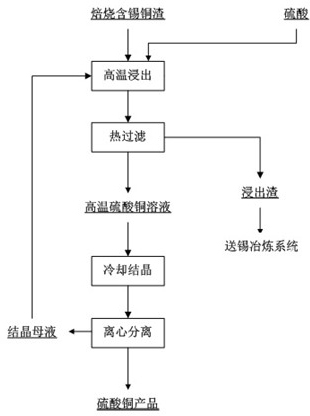

Method used

Image

Examples

Embodiment 1

[0023] (1) Using a sulfuric acid solution with a concentration of 70g / L as a leaching agent, leaching 500kg of roasted copper slag produced in the tin smelting process for 2 hours at 80°C with a solid-to-liquid ratio of 1:3 to obtain a slurry; The roasted copper slag is the copper slag produced in the tin smelting process and then roasted. The metal phase is metal oxide, containing Cu 10wt%, Sn 60wt%, Pb 2.17wt%, As 2.25wt%, Fe 1.95wt%;

[0024] (2) Filter the leached slurry obtained in step (1) at 80°C to obtain leaching solution and leaching slag respectively; during the leaching process, impurities such as tin, arsenic, and iron are suppressed in the slag, and copper is selectively leached into the In the leaching solution; and the copper (total copper) in the leaching solution is 70.6g / L, and the concentration of sulfuric acid is 50g / L; the resulting leaching residue (after washing) is returned to the main process of tin smelting for the recovery of other valuable metals (...

Embodiment 2

[0027] (1) Using a sulfuric acid solution with a concentration of 250g / L as a leaching agent, leaching 700kg of roasted copper slag produced during the tin smelting process for 1.5 hours at 90°C with a solid-to-liquid ratio of 1:4 to obtain a slurry; The roasted copper slag is the copper slag produced in the tin smelting process and then roasted. The metal phase is metal oxide, containing Cu 21.19wt%, Sn 46.77wt%, Pb 2.15 wt%, As 1.68 wt% %, Fe 1.35 wt%;

[0028] (2) Filter the leached slurry obtained in step (1) at 90°C to obtain the leaching solution and leaching slag respectively; during the leaching process, impurities such as tin, arsenic, and iron are suppressed in the slag, and copper is selectively leached into the In the leaching solution; and the copper (total copper) in the leaching solution is 81.3g / L, and the concentration of sulfuric acid is 178g / L; the resulting leaching residue (after washing) is returned to the main process of tin smelting for the recovery of ...

Embodiment 3

[0031](1) Sulfuric acid solution with a concentration of 230g / L was used as a leaching agent, and the roasted copper slag produced during the tin smelting process was leached for 0.5 hours at 98°C with a solid-to-liquid ratio of 1:6 to obtain a slurry; among them, The roasted copper slag is obtained by roasting the copper slag produced in the 700kg tin smelting process. The metal phase is metal oxide, containing 40wt% Cu, 30wt% Sn, 2.07wt% Pb, 1.88wt% As, Fe 2.16 wt%;

[0032] (2) Filter the leached slurry obtained in step (1) at 98°C to obtain the leaching solution and leaching slag respectively; during the leaching process, impurities such as tin, arsenic, and iron are suppressed in the slag, and copper is selectively leached into the In the leaching solution; and the copper (total copper) in the leaching solution is 200g / L, and the concentration of sulfuric acid is 64.8g / L; the resulting leaching residue (after washing) is returned to the main process of tin smelting for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com