Method for preparing monoclinic phase Ga2S3 crystal

A monoclinic phase and microcrystalline technology, applied in the field of material science, to achieve the effects of high yield, good thermal stability, and sufficient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

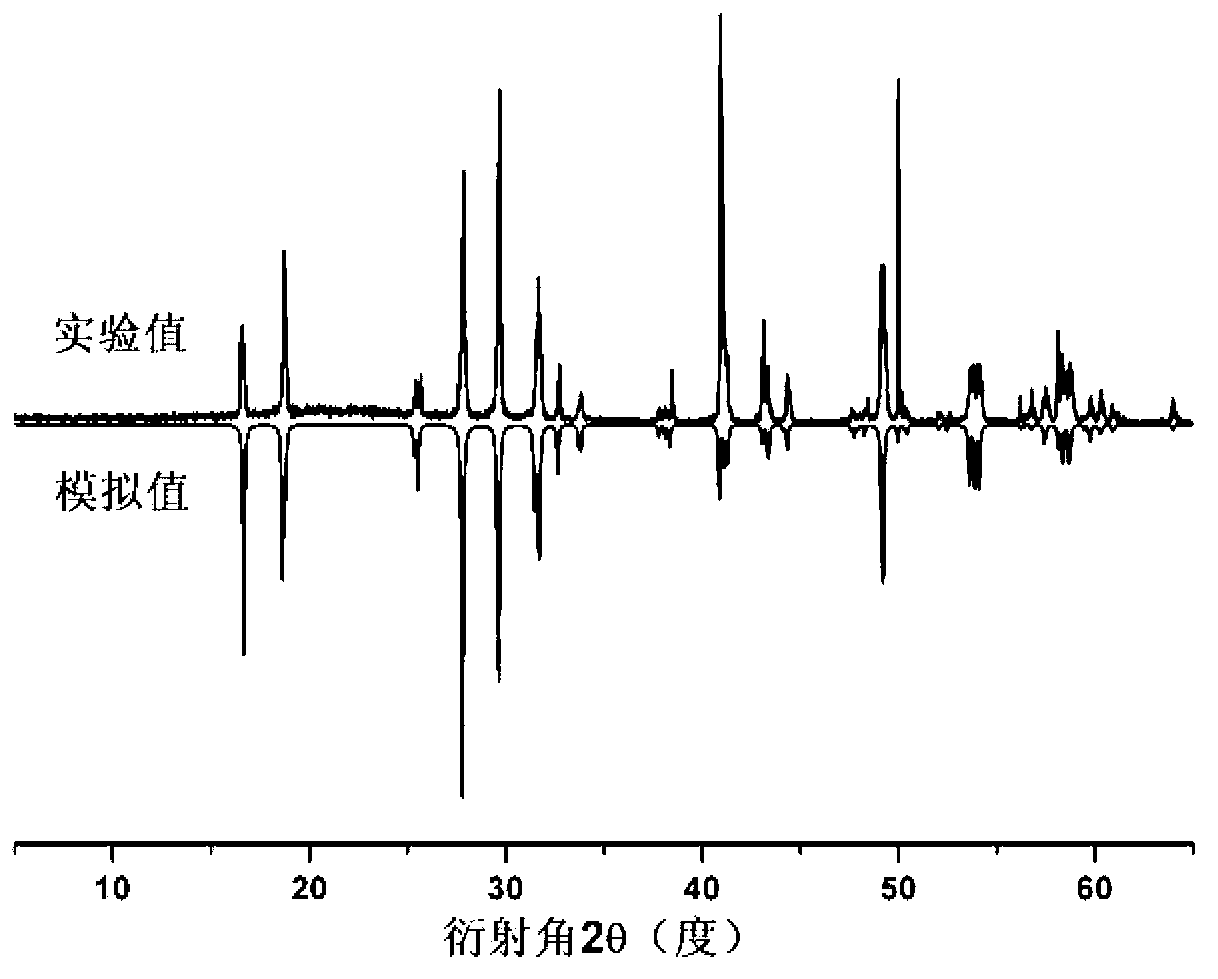

[0023] Example 1: 1 mmol monoclinic Ga 2 S 3 Synthesis

[0024] Weigh 1 mmol of Ga 2 o 3 (187 mg), 2 mmol of B powder (22 mg), 3 mmol of S powder (97 mg), ground and mixed in an agate mortar, and then pressed into tablets, under a vacuum of 2 o 3 , about 1 mmol of monoclinic Ga can be obtained 2 S 3 Polycrystalline powder with a yield of over 90%.

Embodiment 2

[0025]Example 2: Monoclinic Ga 2 S 3 Powder frequency-octave phase-matching test

[0026] Monoclinic Ga 2 S 3 The polycrystalline powder is sieved with a steel sieve to screen powders in six particle size ranges of 30-50, 50-75, 75-100, 100-150, 150-200, and 200-300 m, respectively loading samples and placing them on the laser light path , using a near-infrared CCD to measure their frequency-doubled signal intensities at 1910nm infrared laser wavelengths, and analyze and judge whether the compounds can be phase-matched after drawing. For the test results of powder frequency doubling phase matching, see Figure 4 , it can be seen that the double frequency signal of the sample becomes larger as the particle size increases, so it is judged that the monoclinic Ga 2 S 3 It can be phase matched under 1910nm laser.

Embodiment 3

[0027] Example 3: Monoclinic Ga 2 S 3 Laser Damage Threshold Test for

[0028] Monoclinic Ga 2 S 3 The polycrystalline powder is sieved with a steel sieve to sieve the powder with a particle size range of 50-75 m. After loading the sample, the laser damage threshold is measured under a 1064 nm laser with a pulse width of about 8 ns. The laser power is continuously increased to observe the damage of the sample. Until the sample has a damage spot, record the laser power at this time, and measure the main damage spot area to be 2.45 mm 2 , it can be deduced that the damage threshold of the sample is 174 MW / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com