Organic fertilizer produced from plant straws by aerobic fermentation and preparation method thereof

A technology of plant straw and aerobic fermentation, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of poor effect, low utilization rate, air pollution, water body and other problems, and achieve the stimulation of beneficial microorganisms in the soil activity, promote the formation of aggregate structure, and promote the effect of growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

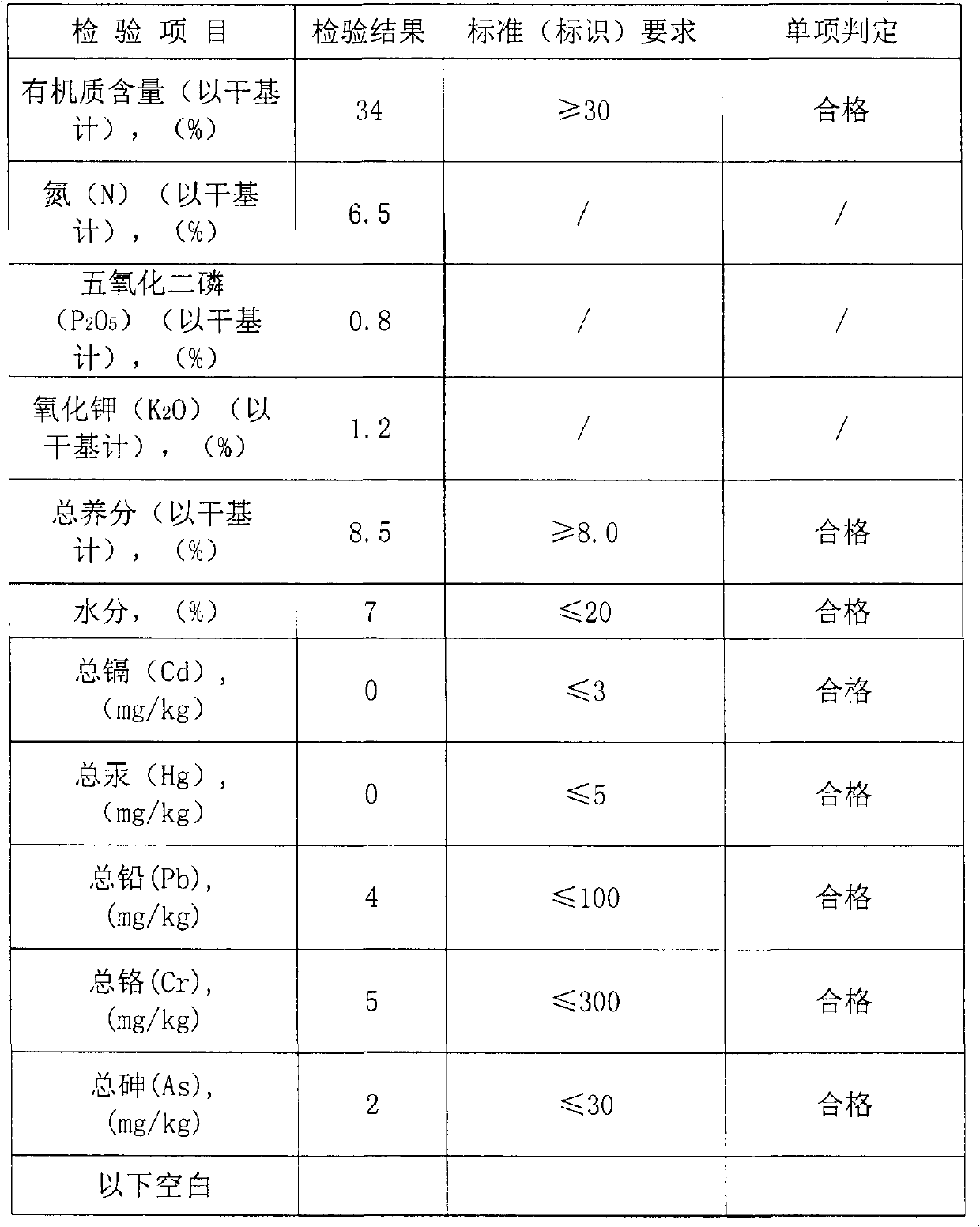

Image

Examples

Embodiment Construction

[0019] Raw materials are prepared according to the following proportions: 60%wt of plant straw with a water content of 30-35%, 20%wt of edible mushroom residue, 14%wt of cake, 5%wt of calcium magnesium phosphate fertilizer, and 1%wt of cellulolytic bacterial agent. Among them, the plant straw is the mixed straw of corn stalks and cotton stalks, the edible fungus residue is the discarded culture medium after planting Flammulina velutipes, the cake is rapeseed cake, which is a by-product after pressing rapeseed oil, and the cellulose decomposing bacteria agent is the content of the invention Bacteria described in.

[0020] Raw materials are processed according to the following process:

[0021] 1. Grinding plant straw with a moisture content of 30-35% with a straw crusher to obtain material A;

[0022] 2. Remove the film of the edible fungus residue, mash and add the formula amount of calcium, magnesium and phosphorus to obtain material B;

[0023] 3. Pulverize the rapeseed ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com