Phosphorodiamidate morpholino oligomer synthetized by solid phase and method thereof

A technology of phosphorodiamidate morpholine and solid-phase synthesis, which is applied in the fields of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as high synthesis cost and expensive resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

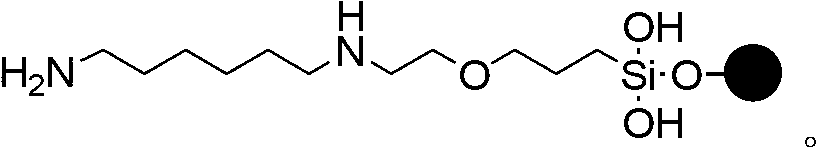

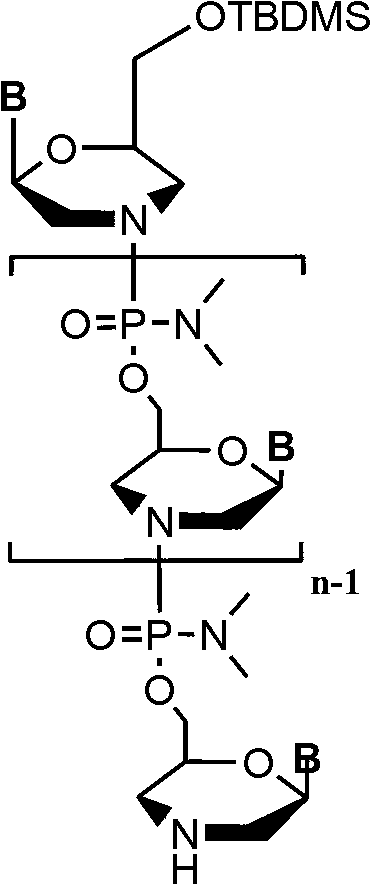

Method used

Image

Examples

Embodiment 1

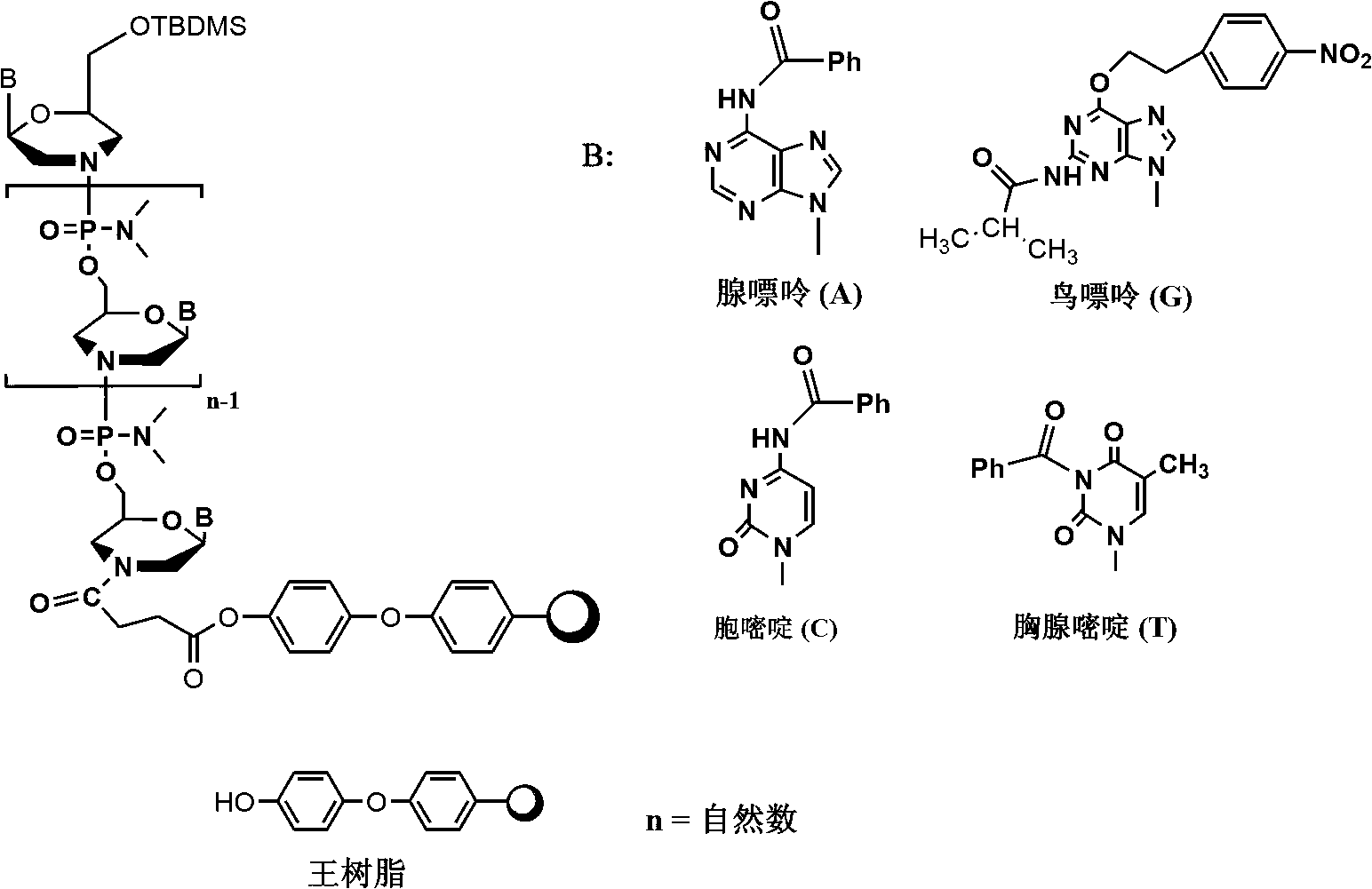

[0065] Embodiment 1: the synthesis of compound PMO (A-T):

[0066] Taking bases A and T as an example, the synthesis route of PMO (A-T) is:

[0067]

[0068] The feed ratio (molar ratio) of T-5 and tert-butyldimethylchlorosilane is 1 / 1.3, dissolved in dichloromethane. Add imidazole under stirring at room temperature, and the molar ratio of the added amount of imidazole to the morpholino derivative is 3 / 1. After reacting for 5 hours, the reactant was washed with water, dried with anhydrous sodium sulfate, and the crude product T-6 was obtained as a colorless oil after removing the solvent.

[0069] Second step reaction:

[0070]

[0071] T-6 was dissolved in trifluoroacetic acid containing acetic acid, the volume ratio of acetic acid and trifluoroacetic acid was 1 / 50, stirred for 4 hours, and then the solvent was removed to obtain T-7.

[0072] The third step reaction:

[0073]

[0074] T-7 was dissolved in water and dioxane (volume ratio: 1 / 1), and sodium carbonat...

Embodiment 2

[0090] Embodiment 2: the synthesis of compound PMO (C-A-T):

[0091] synthetic route:

[0092]

[0093] First step response:

[0094]

[0095] Compounds C-8 and R-4 (molar feeding ratio: 9 / 1) were dissolved in triethylamine dichloromethane solution (concentration: 50 mg / ml) and placed in a solid-phase synthesis tube. R-5 was obtained after overnight reaction and washed with copious amounts of dichloromethane.

[0096] Second step reaction:

[0097]

[0098] Add tetrabutylammonium fluoride tetrahydrofuran solution (solution concentration: 100 mg / ml) into the solid-phase synthesis tube equipped with R-5. Then the solid-phase synthesis tube was placed on a shaker to react for 4 hours, and the solid-phase resin was washed with tetrahydrofuran and dichloromethane to obtain R-6.

[0099] Tenth step reaction:

[0100]

[0101] Under the condition of ammonia water, R-4 was cut off from the solid phase support of Wang resin to obtain PMO (C-A-T). The amino group on t...

Embodiment 3

[0102] Embodiment 3: the synthesis of compound PMO (G-C-A-T):

[0103]

[0104] First step response:

[0105]

[0106] Compounds G-8 and R-6 (molar feed ratio: 2 / 1) were dissolved in triethylamine dichloromethane solution (concentration: 50 mg / ml) and placed in a solid-phase synthesis tube. R-7 was obtained after overnight reaction and washed with copious amounts of dichloromethane.

[0107] Second step reaction:

[0108]

[0109] Add tetrabutylammonium fluoride tetrahydrofuran solution (solution concentration: 100 mg / ml) into the solid-phase synthesis tube equipped with R-7. Then the solid-phase synthesis tube was placed on a shaker to react for 4 hours, and the solid-phase resin was washed with tetrahydrofuran and dichloromethane to obtain R-8.

[0110] The third step reaction:

[0111]

[0112] Under the condition of ammonia water, R-8 was cut off from the solid phase support of Wang resin to obtain PMO (G-C-A-T). The amino group on the terminal morpholine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com