Damping rubber material with low hardness, high-temperature static torque and good durability and preparation method thereof

A shock-absorbing rubber and rubber material technology, which is applied in the field of rubber composite material preparation, can solve the problems of poor durability, high hardness, small static torque, etc., achieve great economic value, improve mechanical strength, and optimize material composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] NBR (grade 1043, with acrylonitrile content of 30%) and styrene-butadiene rubber (grade 1052) in the ratio of 70:30 in parts by mass are meshed in an open mill for a certain period of time, and after several passes , until the mixed glue has a Mooney viscosity of ML at 100°C 1+4 In the range of 40 to 60.

[0030] The masterbatch after the above mixing is moved into the internal mixer, and the mass parts of the masterbatch are counted as 100 parts, 30 parts of N550 carbon black, 15 parts of N330 carbon black, 8 parts of nano-silica with a particle size of 10-30nm , 10 parts of light calcium carbonate, 1 part of silane coupling agent KH550, 1 part of processing aid l-24, 5 parts of zinc oxide, 1 part of stearic acid are added to the internal mixer, and then softening plasticizer phthalic acid is added 10 parts of dibutyl ester, 1.5 parts each of chemical antioxidant RD and antioxidant 4010NA; mix evenly under high temperature and high shear conditions, wherein the intern...

Embodiment 2~7

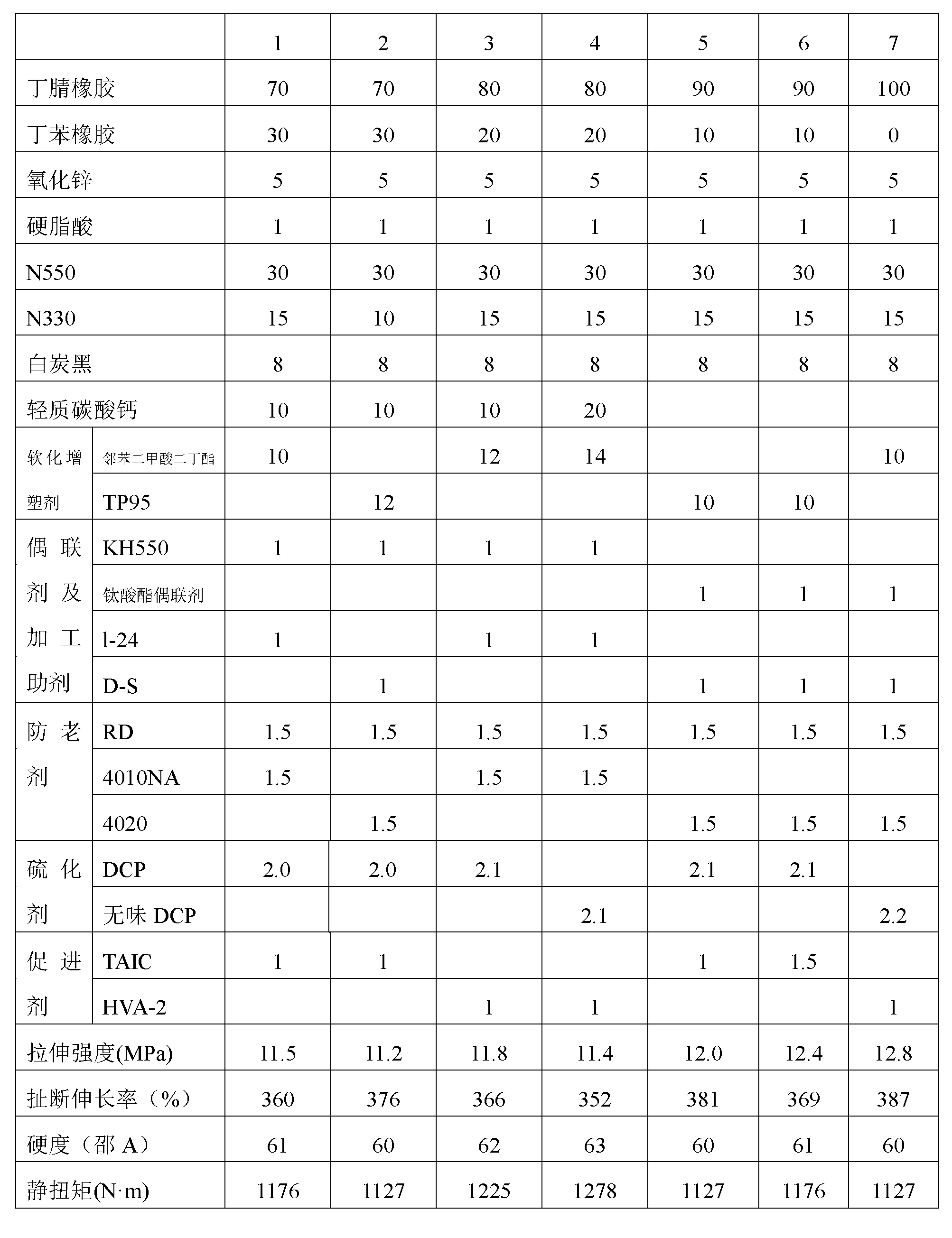

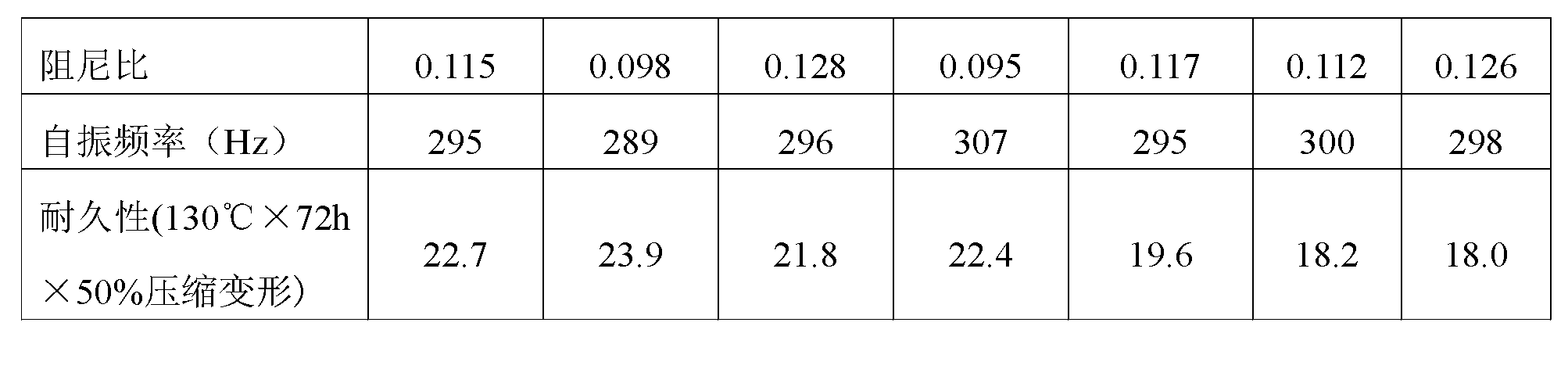

[0033] Example 2~7

[0034]

[0035]

[0036] In a word, the present invention provides a shock-absorbing rubber material with low hardness, high-temperature static torque and good durability and a preparation method thereof. The implementation process is simple and easy, and has good industrialization value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com