Degradable polylactic acid (PLA) composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of degradable polylactic acid composite materials and its preparation, can solve the problems of unsuitable mass production, high mold quality requirements, large equipment investment, etc., and achieve easy control of the production process and excellent mechanical properties , to avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a degradable polylactic acid composite material, which includes the following steps:

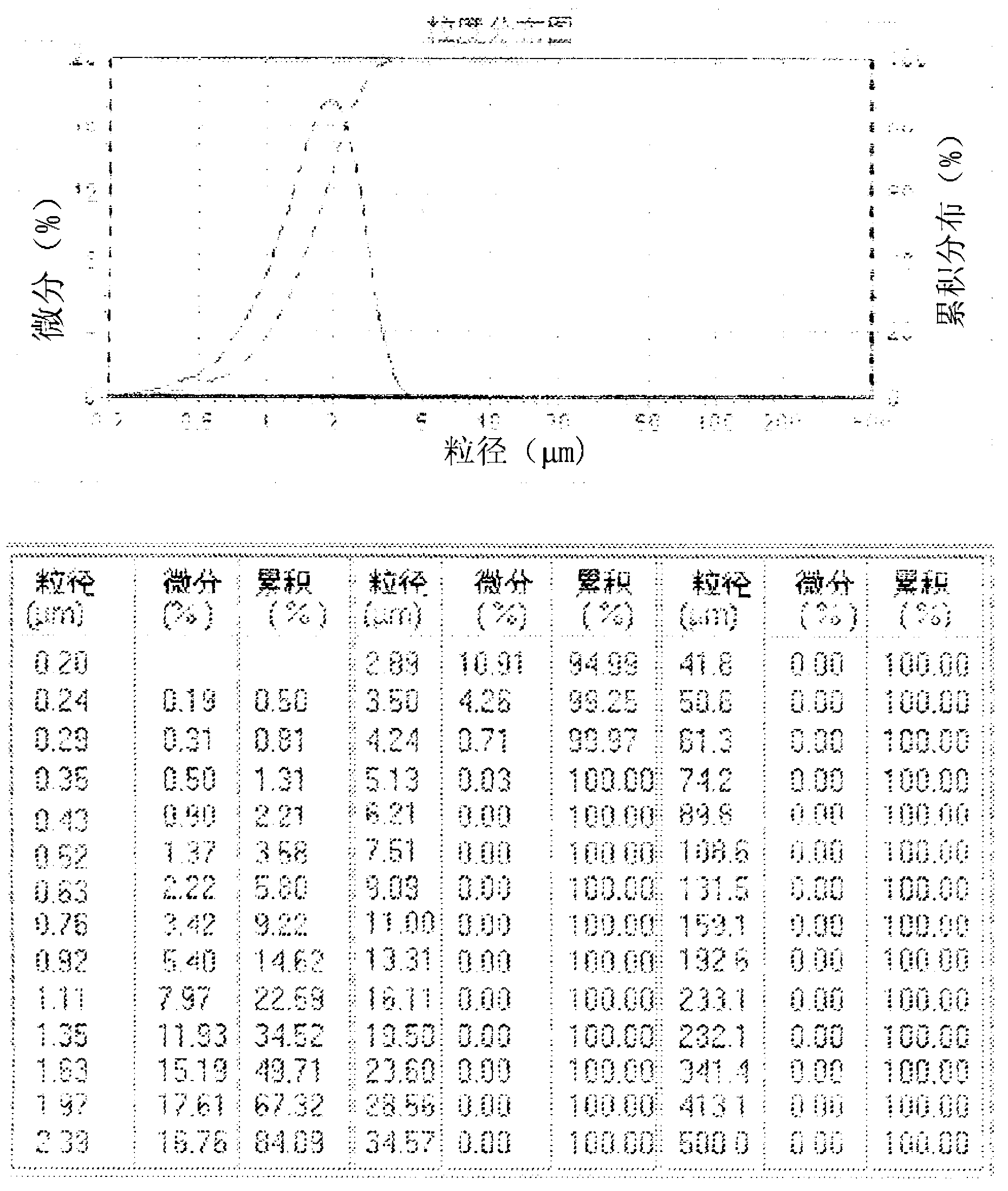

[0027] (1) Superfine crushing of sugarcane leaves: After the sugarcane leaves are dried, they are pre-pulverized on a fine pulverizer (equipment model WFJ-30) to obtain about 300 grams of powder with a particle size of about 1 mm, which is mixed with 1000 milliliters of glycerin After the alcohol is mixed, put it into the HZM-10II type high-frequency vibrating micro-powder mill grinding cylinder for high-frequency grinding, grind for 20 hours and stop for discharging to obtain sugarcane leaf micropowder. Sampling was observed with a graduated microscope and it was found that the average fineness of the sugarcane leaf powder was within 2 μm. After detection by the laser particle size detector, the fineness distribution was as follows: figure 1 shown.

[0028] (2), melt mixing preparation degradable polylactic acid composite material: ado...

Embodiment 2

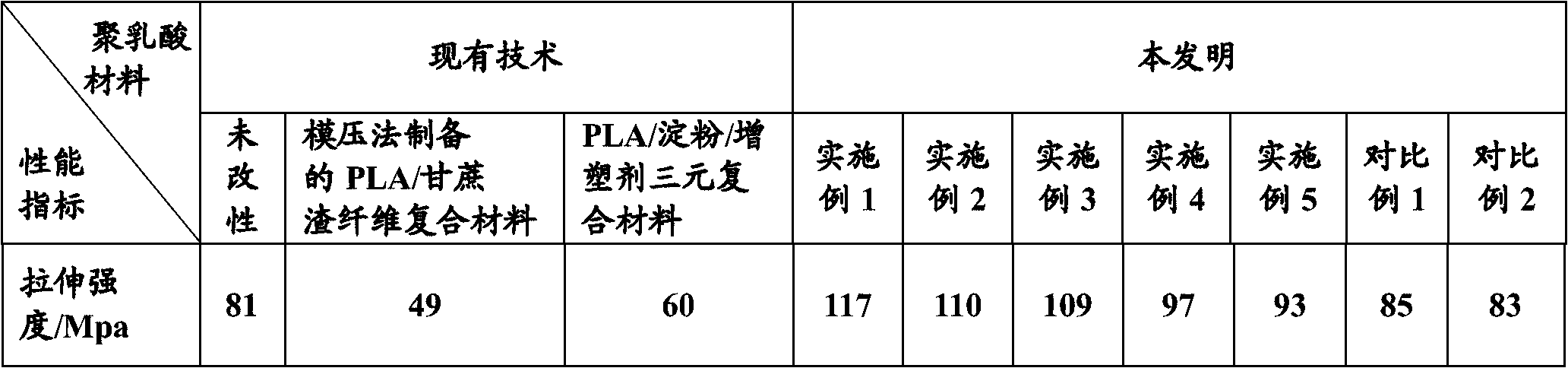

[0030] This embodiment provides a preparation method of a degradable polylactic acid composite material, which is as follows: 480g PLA and 120g PBAT, 200g sugarcane leaf micropowder, 180g PCL and 20g chain extender prepared according to the method of step (1) of Example 1 , after mixing, add twin-screw extruder and carry out melting mixing, and the parameter of melting mixing is as follows (twin-screw extruder; Φ=26mm; L / D=40; The temperature of feed zone to each district of die head is successively: 160°C, 190°C, 200°C, 200°C, 200°C, 210°C, 210°C, 210°C, 200°C, 200°C; pressure 56; torque 64%; feeding rate 20s), PLA was produced at about 240°C The blend is then extruded and granulated, and dried to obtain polylactic acid composite material slices. The polylactic acid composite slices were injection molded, the mold temperature was 120°C, and the cooling time was 130 seconds. The formed sheets were tested, and the results are shown in Table 1.

Embodiment 3

[0032]This embodiment provides a preparation method of a degradable polylactic acid composite material, which is as follows: 300g PLA and 300g PBAT, 280g sugarcane leaf micropowder, 100g PCL and 20g chain extender prepared according to the method of step (1) of Example 1 , after mixing, add twin-screw extruder and carry out melting mixing, and the parameter of melting mixing is as follows (twin-screw extruder; Φ=26mm; L / D=40; The temperature of feed zone to each district of die head is successively: 160°C, 190°C, 200°C, 200°C, 200°C, 210°C, 210°C, 210°C, 200°C, 200°C; pressure 56; torque 64%; feeding rate 20s), PLA was produced at about 240°C The blend is then extruded and granulated, and dried to obtain polylactic acid composite material slices. The polylactic acid composite slices were injection molded, the mold temperature was 120°C, and the cooling time was 130 seconds. The formed sheets were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com