Method for extracting gallium through ultrasonic-assisted intensified electrolysis

An electrolytic extraction and ultrasonic-assisted technology, which is applied in the direction of photographic auxiliary process, process efficiency improvement, photographic process, etc., to achieve the effects of reduced activity, stable operation, and improved reaction rate and current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

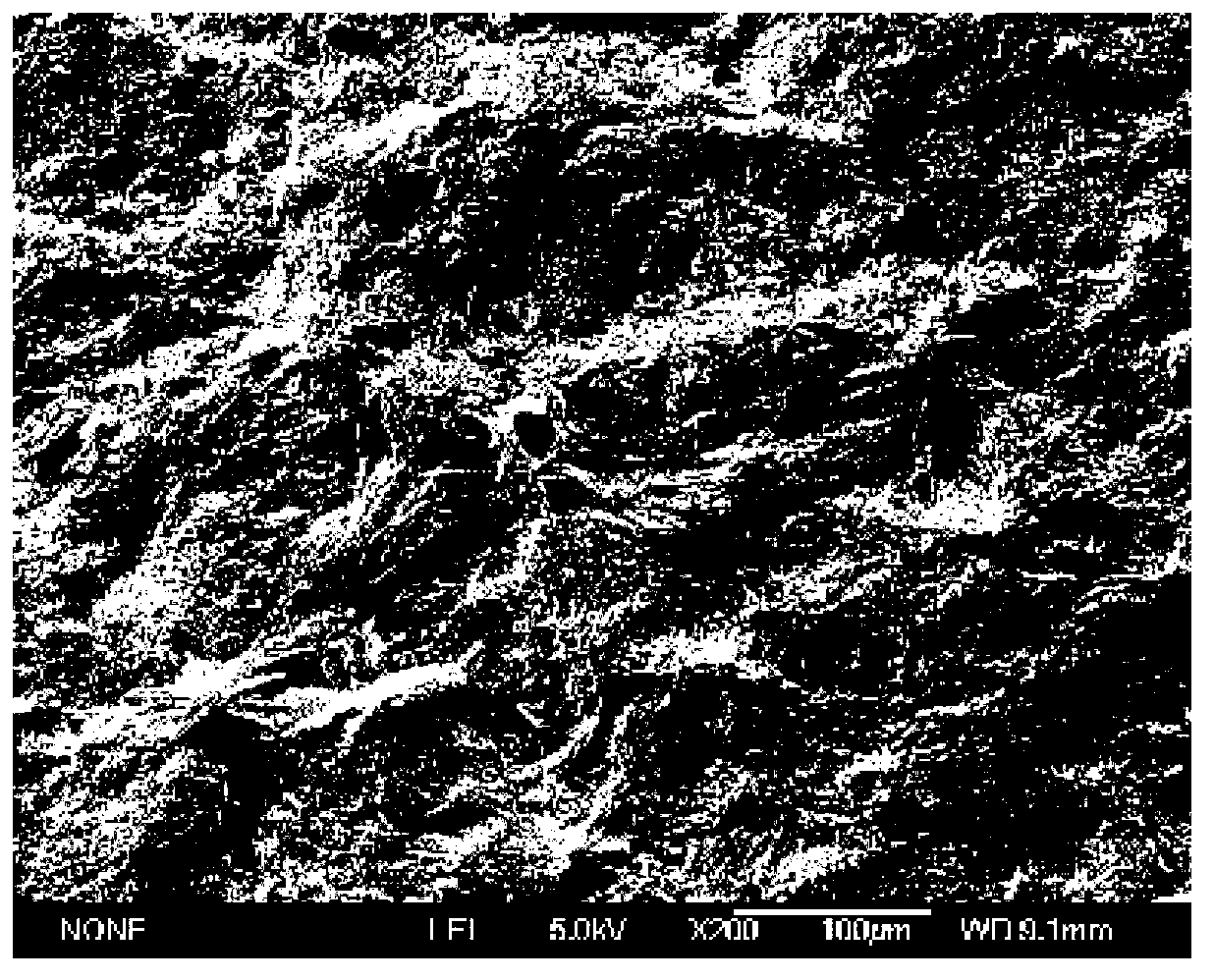

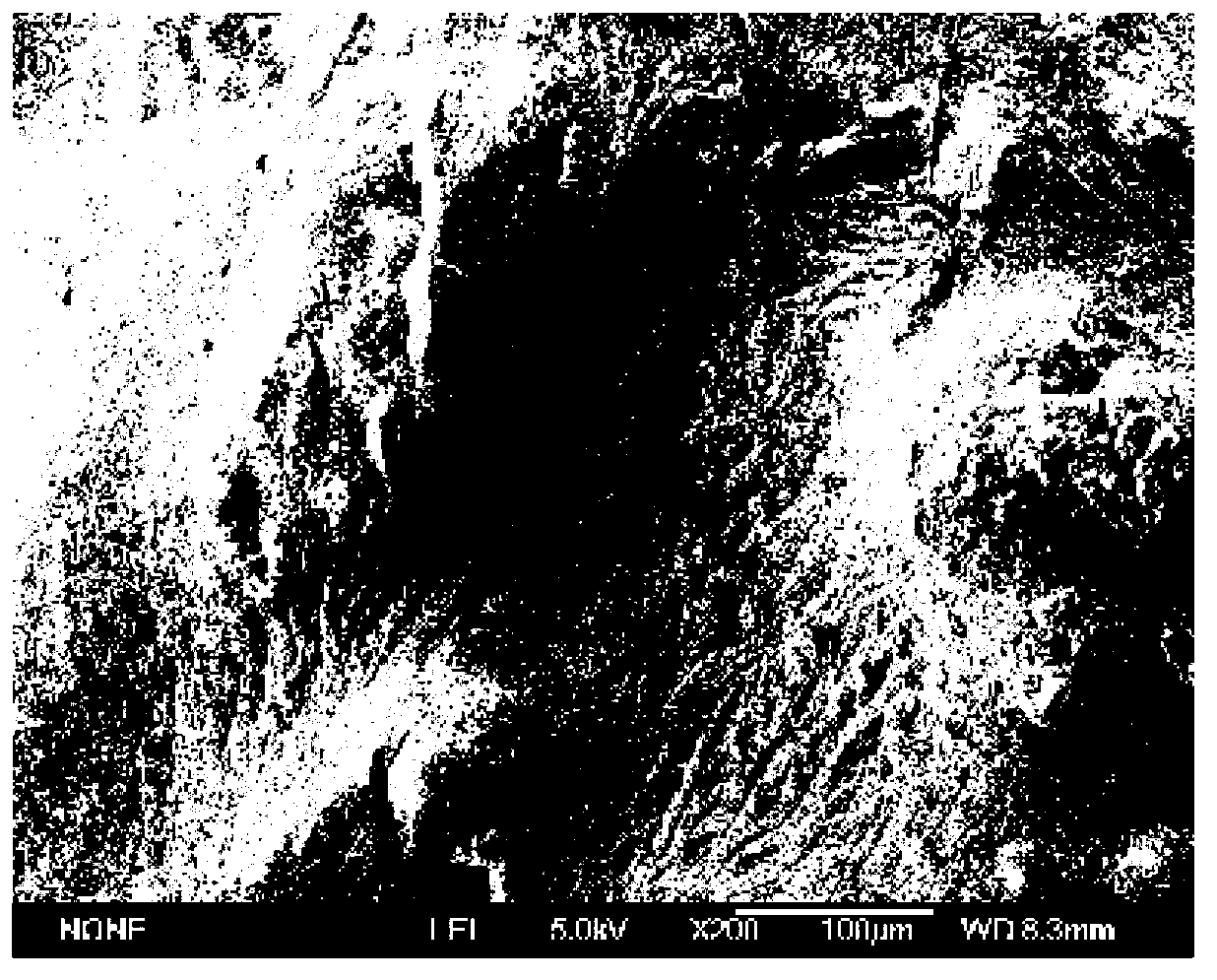

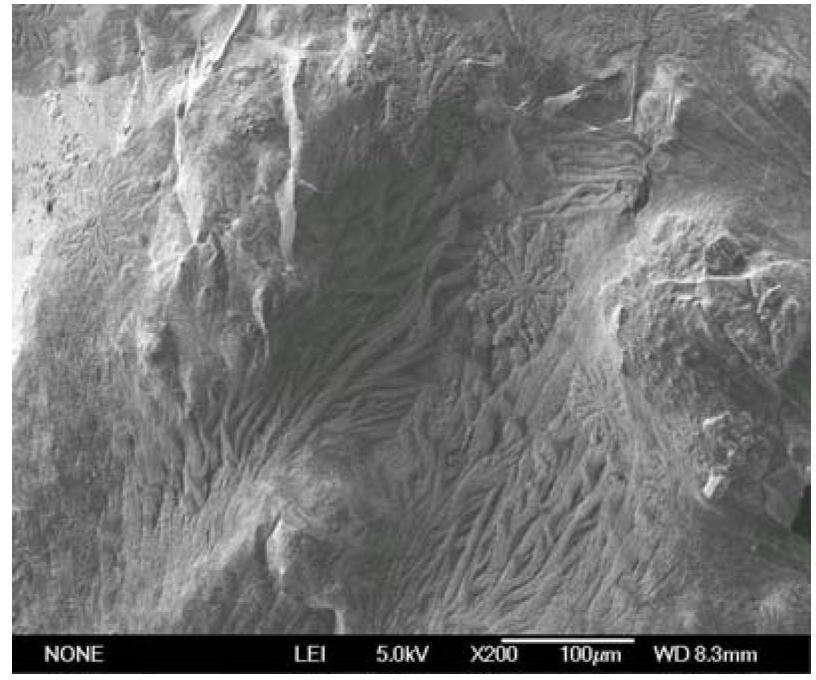

Image

Examples

Embodiment 1

[0023] (1) Prepare 750mL of electrolyte solution with a mass concentration of Ga(Ⅲ) (representing trivalent gallium metal) of 1g / L and a mass fraction of NaOH of 10%;

[0024] (2) Stainless steel electrodes are used, the anode is derusted and degreased before electrolysis, and the cathode is derusted and degreased as well as anode activation pretreatment;

[0025] (3) Place the electrolytic cell in an ultrasonic field, control the electrolysis temperature to 40°C, use direct current, and the current density is 1000A / m 2 , under the conditions of ultrasonic frequency 40KHz, ultrasonic power 120W, electrolysis for 3 hours, the current efficiency of electrolytically extracting gallium metal is 4.4%; the same situation under the condition of non-ultrasonic field, the current efficiency is only 3.1%.

Embodiment 2

[0027] (1) Prepare 750mL of electrolyte solution with Ga(Ⅲ) mass concentration 1g / L and NaOH mass fraction 10%;

[0028] (2) Stainless steel electrodes are used, the anode is derusted and degreased before electrolysis, and the cathode is derusted and degreased as well as anode activation pretreatment;

[0029] (3) Place the electrolytic cell in an ultrasonic field, control the electrolysis temperature to 40°C, use direct current, and the current density is 1000A / m 2 , under the conditions of ultrasonic frequency 40KHz, ultrasonic power 200W, electrolysis for 3 hours, the current efficiency of electrolytically extracting metal gallium is 4.6%; the same situation under the condition of non-ultrasonic field, the current efficiency is only 3.1%.

Embodiment 3

[0031] (1) Prepare 750mL of electrolyte solution with Ga(Ⅲ) mass concentration 2.7g / L and NaOH mass fraction 10%;

[0032] (2) Stainless steel electrodes are used, the anode is derusted and degreased before electrolysis, and the cathode is derusted and degreased as well as anode activation pretreatment;

[0033] (3) Place the electrolytic cell in an ultrasonic field, control the electrolysis temperature to 40°C, and use direct current with a current density of 500A / m 2 , under the condition of ultrasonic frequency 40KHz, ultrasonic power 500W, electrolysis for 6h, the current efficiency of electrolytically extracting metal gallium is 20.2%; the same situation under the condition of non-ultrasonic field, the current efficiency is only 12.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com