Method for preparing transparent biological substrate with spectral enhancement function

A spectrum-enhancing, bio-based technology, applied in the field of preparation of transparent bio-substrates, can solve the problems of metal materials being opaque, and achieve the effect of wide range of spectral enhancement conditions, good repeatability, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

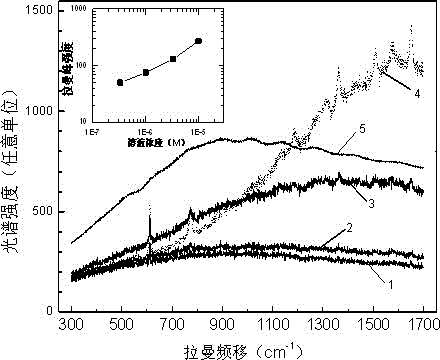

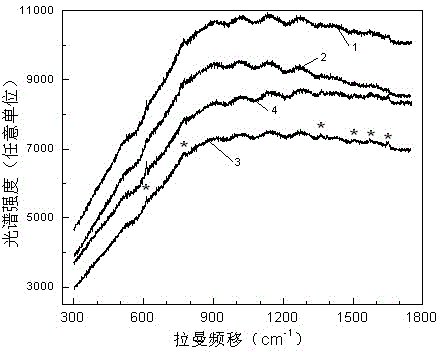

Examples

Embodiment 1

[0021] (1) Chemically clean the glass substrate: First, use anhydrous acetone to ultrasonically clean the optical carrier / cover slip (domestic brand - Sailing brand, model 7101) for 10 minutes to remove the grease on the surface of the optical carrier / cover slip and adsorb impurities. All commercially available anhydrous acetones can be used in the present invention, the same below.

[0022] Then put the optical slide / cover slip into the alkaline mixed solution of ammonia, hydrogen peroxide and water and boil for 10 minutes. : 1: 6 preparation, after cooking, rinse off the residual alkaline cleaning solution on the slide / cover slip with deionized water.

[0023] Then put the optical slide / cover slip into the acidic mixed solution of hydrochloric acid, hydrogen peroxide and water and boil for 10 minutes. 1:6 preparation, after cooking, rinse off the residual acidic cleaning solution on the slide / cover slip with deionized water and dry it.

Embodiment 2

[0029] (1) Chemically clean the glass substrate: First, use anhydrous acetone to ultrasonically clean the optical carrier / cover slip (domestic brand - Sailing brand, model 7101) for 15 minutes to remove the grease on the surface of the optical carrier / cover slip and adsorb impurities.

[0030] Then put the optical slide / cover slip into the alkaline mixed solution of ammonia, hydrogen peroxide and water and boil for 14 minutes. : 1: 6 preparation, after cooking, rinse off the residual alkaline cleaning solution on the slide / cover slip with deionized water.

[0031] Then put the optical slide / cover slip into the acidic mixed solution of hydrochloric acid, hydrogen peroxide and water and boil for 9 minutes. The acidic mixed solution is composed of 36% hydrochloric acid, 30% hydrogen peroxide and deionized water by volume ratio: 1:6 preparation, after cooking, rinse off the residual acidic cleaning solution on the slide / cover slip with deionized water and dry it.

[0032] (2) Et...

Embodiment 3

[0036] (1) Chemically clean the glass substrate: First, use anhydrous acetone to ultrasonically clean the optical carrier / cover slip (domestic brand - Sailing brand, model 7101) for 8 minutes to remove the grease on the surface of the optical carrier / cover slip and adsorb impurities.

[0037] Then put the optical slide / cover slip into the alkaline mixed solution of ammonia, hydrogen peroxide and water and boil for 15 minutes. : 1: 6 preparation, after cooking, rinse off the residual alkaline cleaning solution on the slide / cover slip with deionized water.

[0038] Then put the optical slide / cover slip into the acidic mixed solution of hydrochloric acid, hydrogen peroxide and water and boil for 15 minutes. 1:6 preparation, after cooking, rinse off the residual acidic cleaning solution on the slide / cover slip with deionized water and dry it.

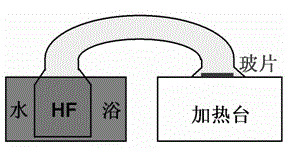

[0039] (2) Etching step: Etching the surface of the glass substrate: placing the dried optical carrier / cover glass on a heating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com