Rich-lithium ternary laminar lithium ion battery cathode material

A lithium-ion battery, ternary layered technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uneven particles, low reaction efficiency, complex process, etc., to achieve uniform particle size, simple process, and cycle life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

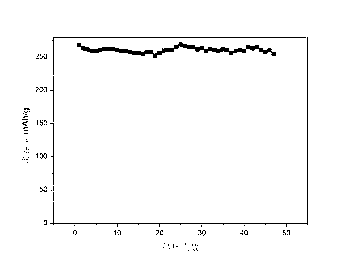

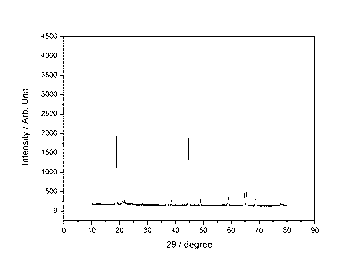

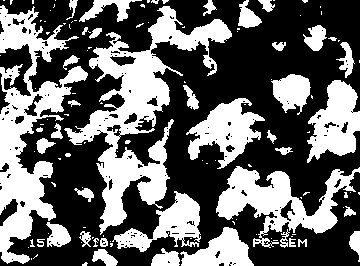

[0029] The preparation chemical formula is Li 1.2 mn 0.56 Ni 0.16 co 0.08 o 2 Lithium manganese oxide cathode material. According to the stoichiometric ratio of 1.2:0.56:0.16:0.08, 0.12 mol lithium acetate, 0.056 mol manganese acetate, 0.016 mol nickel acetate, 0.008 mol cobalt acetate and 0.1 mol alginic acid were weighed and dissolved in 500 ml deionized water, controlled at 70 °C, and then Add ammonia water dropwise to control the pH value to 7, and keep stirring until the water evaporates to dryness. After obtaining the sol-gel precursor, it is placed in vacuum drying at 120 °C for 12 h, and then calcined in a muffle furnace at 550 °C for 5 h in an air atmosphere. , the heating rate was 5 ℃ / min, after natural cooling, it was taken out and ground, and then calcined at 900 ℃ for 15 h, the heating rate was 5 ℃ / min, and then it was naturally lowered to room temperature. The prepared material was assembled into a button battery, and the charge and discharge test was carrie...

Embodiment 2

[0031] The preparation chemical formula is Li 1.2 mn 0.524 Ni 0.176 co 0.1 o 2 Lithium manganese oxide cathode material. Weigh 0.12 mol of lithium acetate, 0.0524 mol of manganese acetate, 0.0176 mol of nickel acetate, 0.01 mol of cobalt acetate and 0.14 mol of ammonium oxalate according to the stoichiometric ratio of 1.2:0.524:0.176:0.1 and dissolve them in 500 ml of deionized water at 70°C, then Ammonia water was added dropwise to control the pH value to 7, and stirring was continued until the water was evaporated to dryness. After the sol-gel precursor was obtained, it was vacuum-dried at 120 °C for 12 h, and then calcined at 550 °C for 5 h in an air atmosphere in a muffle furnace. The heating rate was 5 ℃ / min. After natural cooling, the samples were taken out and ground, and then calcined at 900 ℃ for 15 h. The heating rate was 5 ℃ / min, and then dropped to room temperature naturally. The prepared material was assembled into a button battery, and the charge and dischar...

Embodiment 3

[0033] The preparation chemical formula is Li 1.2 mn 0.524 Ni 0.176 co 0.1 o 2 Lithium manganese oxide cathode material. According to the stoichiometric ratio of 1.2:0.524:0.176:0.1, 0.12 mol lithium acetate, 0.0524 mol manganese acetate, 0.0176 mol nickel acetate, 0.01 mol cobalt acetate and 0.14 mol malic acid were weighed and dissolved in 500 ml deionized water, controlled at 70 °C, and then Ammonia water was added dropwise to control the pH value to 7, and stirring was continued until the water evaporated to dryness. After obtaining the sol-gel precursor, it was vacuum-dried at 120 °C for 12 h, and then calcined at 550 °C for 5 h in an air atmosphere in a muffle furnace. The heating rate was 5 ℃ / min. After natural cooling, the samples were taken out and ground, and then calcined at 900 ℃ for 15 h. The heating rate was 5 ℃ / min, and then dropped to room temperature naturally. The prepared material was assembled into a button battery, and the charge-discharge test was pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com