Loaded olefin polymerization solid catalyst ingredient, and preparation method and application thereof

A solid catalyst, olefin polymerization technology, applied in the field of olefin polymerization solid catalyst components and preparation, can solve the problems of large relative molecular weight, low melt index, high melt index, etc., and achieve good bulk density, good shape and high hydrogen regulation The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of solid catalyst component provided by the invention comprises the following steps:

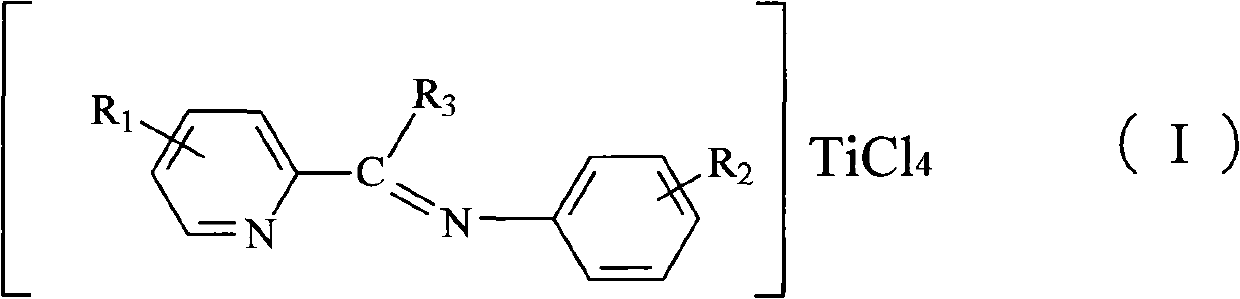

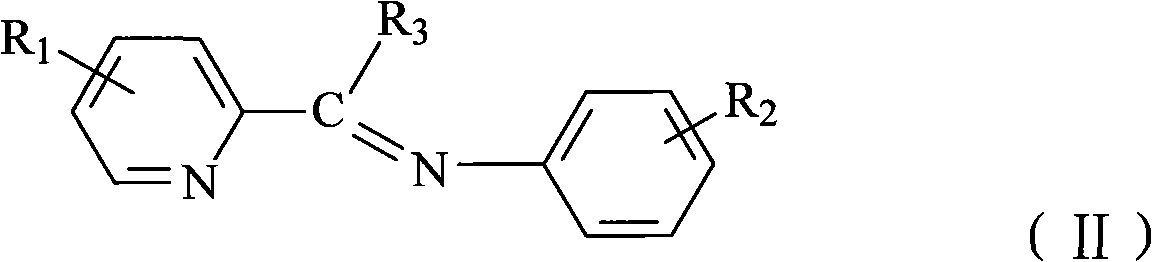

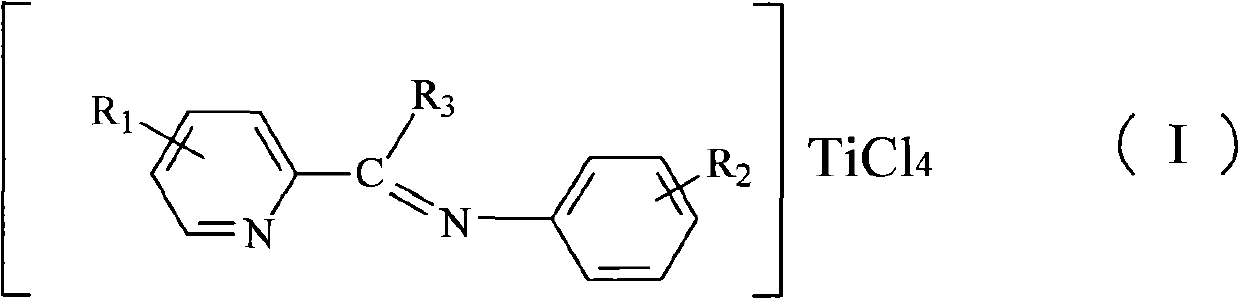

[0018] (1) Prepare the active component solution: dissolve the pyridine-2-alkylimine compound shown in the formula (II) in the halogenated alkane, add TiCl 4 , the pyridine-2-alkylimine compound and TiCl 4 The molar ratio is 1:1.1~15.0,

[0019]

[0020] In formula (II), R 1 , R 2 Respectively, the single or multiple substituents on the pyridine ring and the aniline ring are selected from hydrogen, C 1 ~C 6 Alkyl, phenyl or C 7 ~C 8 Aralkyl, R 3 selected from hydrogen or C 1 ~C 3 the alkyl,

[0021] (2) Preparation of catalyst: Fully dissolve the magnesium-containing compound with the general formula ClMg(OR) n(ROH) in halogenated alkanes, add activated SiO 2 , fully impregnated, after impregnating, add the active component solution prepared in step (1) to the impregnated solid and impregnate again, the gained solid is washed and dried with inert h...

example 1

[0049] Preparation of the magnesium-containing compound carrier used in the catalyst of the present invention.

[0050] Get 1.0g (41.7mmol) magnesium powder, put into there-necked bottle under nitrogen protection, add 0.1g I 2 and 60mL (80g) CH 2 Cl 2 , stirred at 41° C. for 5 minutes, and slowly added dropwise 5 mL (86.1 mmol) of ethanol, the reaction proceeded violently and produced a large number of bubbles. After the dropwise addition was completed, the reaction was stirred at this temperature for 10 hours until the magnesium powder was completely reacted. The reaction product was cooled to 25° C. to obtain a colorless transparent solution, and 60 mL of hexane was added with stirring, and white crystals were precipitated, and the stirring was continued for 60 minutes. Filter and dry the solid at 25°C to obtain a white powdery crystal, which is carrier A, and its expression is ClMg(OC 2 h 5 )·0.63(C 2 h 5 OH).

[0051] The contents of each component of the carrier A...

example 2

[0053] The carrier was prepared in the same manner as in Example 1, except that 60 mL (89 g) of CHCl 3 instead of CH 2 Cl 2 , and react magnesium powder with ethanol at 61°C to obtain carrier B, whose expression is ClMg(OC 2 h 5 )·0.81(C 2 h 5 OH), the content of each component of carrier B is: Mg, 16.67 mass %; Cl, 20.92 mass %; (OC 2 h 5 ), 56.40% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com