Gangue comprehensive utilization method

A technology of coal gangue and kaolinite, which is applied in the field of comprehensive utilization of solid carbon-containing materials, can solve problems such as insufficient utilization of coal gangue and environmental pollution, and achieve the effects of increasing added value, improving utilization efficiency, and making full use of waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

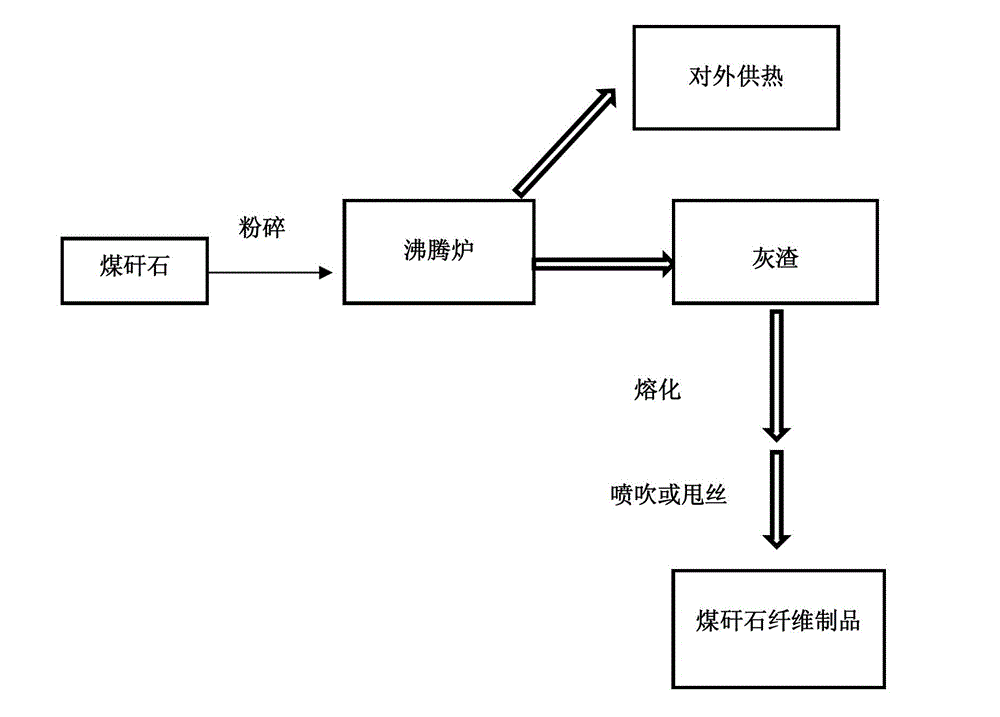

Method used

Image

Examples

Embodiment 1

[0031] Coal gangue taken from Shuozhou area, Shanxi, has a calorific value of 6.27-12.6MJ / kg, and a carbon content of 10-20%. The components other than carbon are shown in Table 2, where "others" include TiO 2 ,P 2 o 5 、K 2 O, Na 2 O and V 2 o 5 Wait. The test method is XRF (X-ray fluorescence spectroscopy)

[0032] Table 2: Composition of coal gangue

[0033] Inorganic components

[0034] Coal gangue is pulverized by a pulverizer so that the particle size is less than or equal to 10mm, and burned in a boiling furnace. The temperature of the boiling material layer (fluidized bed) is 800-1100°C during combustion. The fluidized fluidized furnace is connected to the boiler to generate heat for external supply for domestic or industrial heat. The white inorganic ash after burning is melted in an induction furnace at 1600°C. In the gangue ash, add 8% bauxite (containing Al 3 o 2 The weight ratio is 55%), and the melted mixture is blown into a wire making machine...

Embodiment 2

[0036] The coal gangue taken from the Luliang area of Shanxi has a calorific value of 7.54-12.6MJ / kg. The carbon content is 20-30%, and the components other than carbon are shown in Table 3, where "others" include TiO 2 ,P 2 o 5 、K 2 O, Na 2 O and V 2 o 5 Wait.

[0037] Table 3: Composition of coal gangue

[0038] Inorganic components

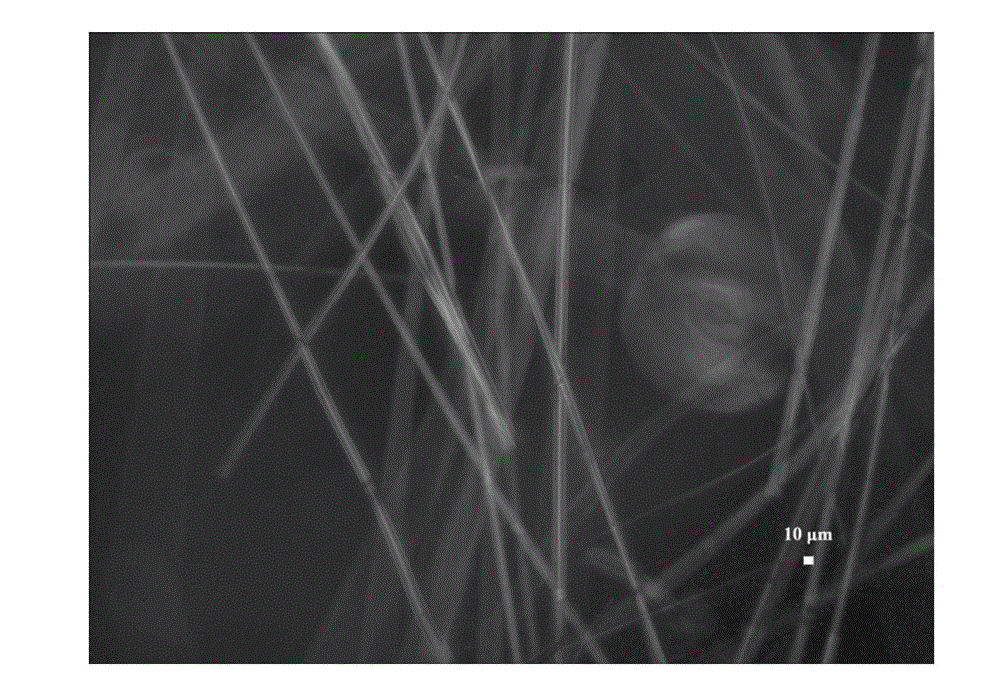

[0039] Coal gangue is pulverized by a pulverizer so that the particle size is less than or equal to 10mm, and burned in a boiling furnace. The temperature of the boiling material layer (fluidized bed) is 950-1100°C during combustion. The boiling furnace is connected to the boiler, and the steam generated drives the steam turbine to generate electricity. The white inorganic ash after burning is melted in an induction furnace at 1700°C, and bauxite (containing Al 3 o 2 The weight ratio is 45%), and the molten mixture is blown into a silk machine to obtain inorganic coal gangue fibers. The fiber has a diameter of 2-8 μm and ...

Embodiment 3

[0041] Coal gangue taken from the Luliang area of Shanxi, with a calorific value of 6.27-12.6MJ / kg, is pulverized by a pulverizer to make the particle size less than or equal to 10mm, and burned in a boiling furnace. When burning, the boiling material layer (fluidized bed Layer) temperature is 800 ~ 1100 ℃. The fluidized fluidized furnace is connected to the boiler, which will generate heat for external supply. The white inorganic ash slag after burning is melted in an induction furnace at 2000° C., and in the gangue ash slag, bauxite (containing Al 3 o 2 weight ratio 42%), the molten mixture uses the centrifugal wire spinning method, and the liquid obtained by melting flows into the disc type wire spinning machine, and the rotating speed of the centrifugal disc in the disc type wire spinning machine is 2000r / min~10000r / min, and the silk that is thrown out is cooled Inorganic fibers are then obtained. The fiber has a diameter of 2-10 μm and an aspect ratio of 1000-2000. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com