Edible oil quality inspection method based on 1H-nuclear magnetic resonance (NMR) fingerprint spectra and multivariate analysis

A 1H-NMR, multivariate analysis technology, applied in the field of food analysis, can solve the problems of complex and time-consuming practical application of pretreatment, low accuracy rate, etc., achieve the effect of simple measurement method, increase accuracy rate, and avoid human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

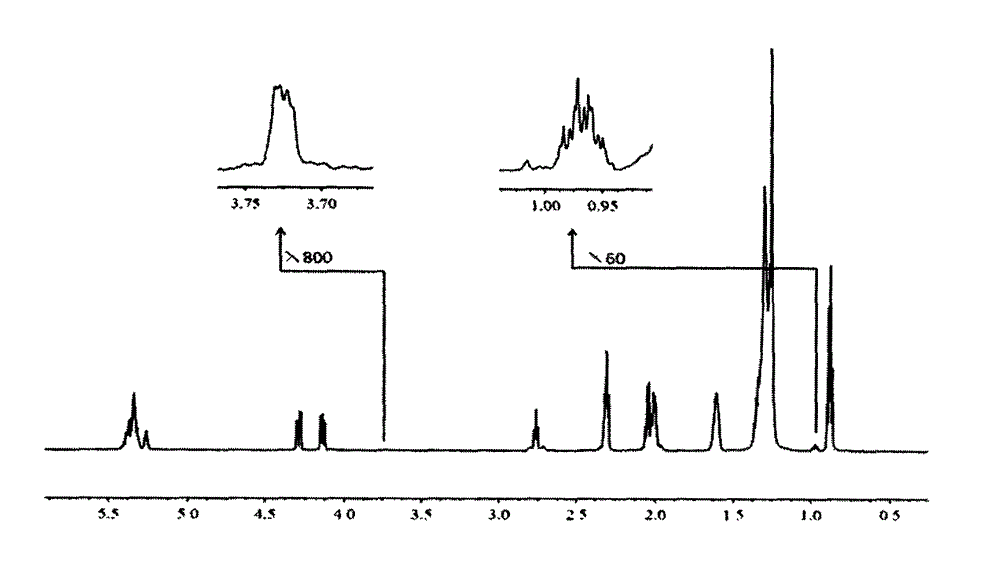

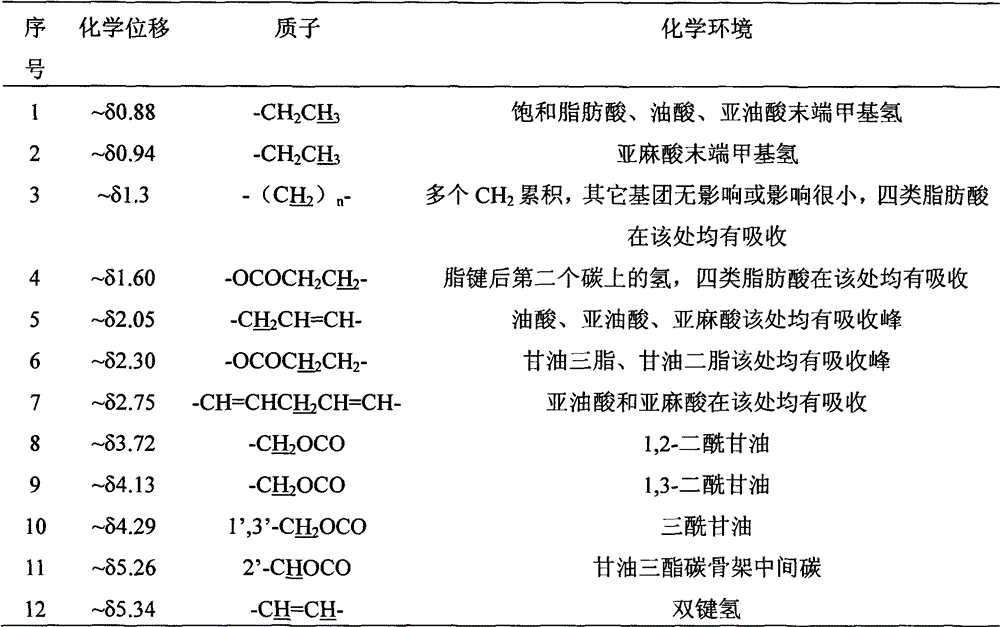

[0026] Take 1ml sample and dissolve it in about 4ml CDCl 3 , Adjust its mass ratio to 1:7, vortex and mix for 5 seconds, take 0.6ml into the NMR tube, and measure after equilibrating the temperature for 5 minutes to room temperature. The experiment was performed on a Bruker Avance III nuclear magnetic resonance instrument with a power of 600MHz.

[0027] 1 H-NMR spectrum measurement method: time domain 32K; 90 pulse time: 11μs; spectrum width: 10ppm; relaxation: 2s; signal detection time: 2.73s; each free induction attenuation scan number: 32, virtual scan number: 4. The chemical shift is in ppm, and trimethylsilane (TMS, d=0) is used as the internal standard.

[0028] NMR spectrum data processing: operate on Bruker TOPSPIN 2.1 software. in 1 In the H-NMR spectrum, the total peak area is used as the unit 1, and the integral values of various protons are normalized. Derive the relative content of various protons to prepare for the next data processing.

[0029] Cluster analysis a...

Embodiment 2

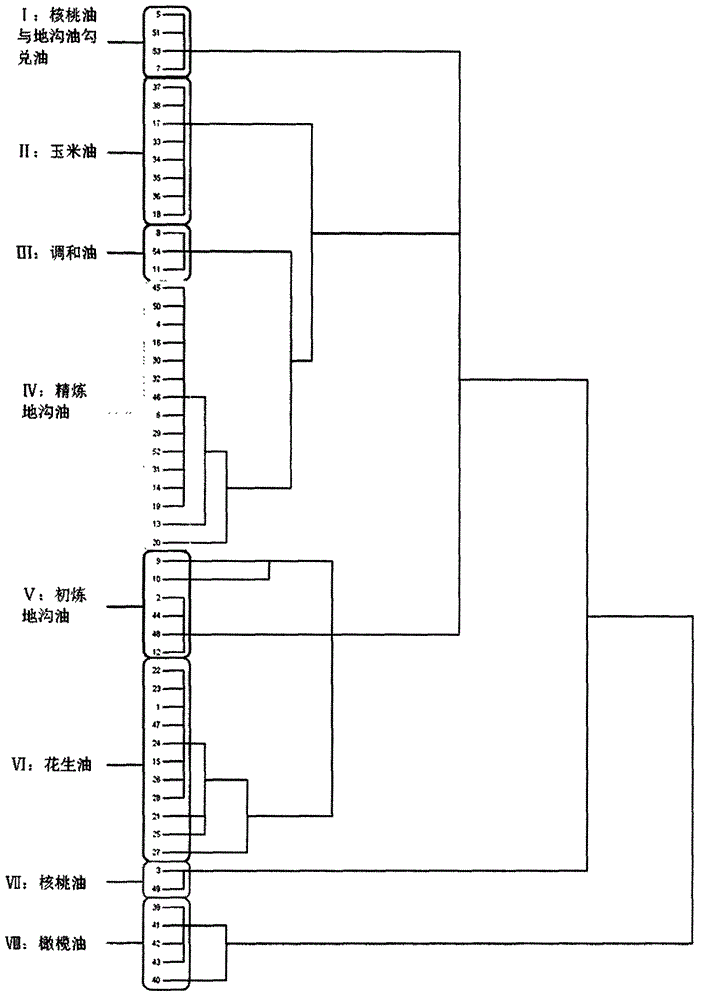

[0032] Collect all kinds of edible oils on the market and various types of seized waste oils obtained from the public security department as low-quality oils, a total of 54 types and 8 categories (see Table 2 for the sample table), cluster analysis and classification according to the method in Example 1 See the result figure 2 , Cluster analysis can accurately classify 54 species into 8 categories.

[0033] Table 2 Sample name and number

[0034]

[0035]

Embodiment 3

[0037] Repeat Example 1 according to the same steps, the difference lies in: configure 37 unknown samples for discriminant analysis. 37 unknown samples were configured by other units according to blind sample configuration requirements, and then provided to this method for determination. The measurement results are shown in Table 3, and the accuracy rate is 92%.

[0038] Table 337 Discriminant Analysis Results of Unknown Samples

[0039]

[0040]

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com