A kind of active optical module controller

A module controller, source light technology, applied in the direction of optical fiber transmission, etc., can solve the problems of miniaturization of optical modules, difficult production process, high production cost, reduce the risk of mutual interference of small signals, reduce space and chip tube The number of feet, the effect of improving overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

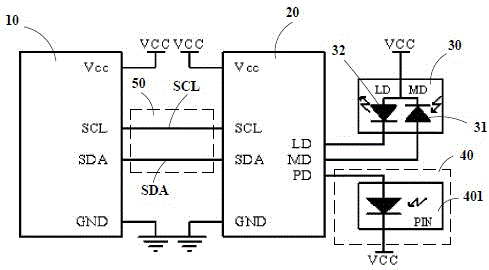

[0026] like figure 1 As shown, the photodiode unit 40 includes a PIN diode 401 , one end of the PIN diode 401 is electrically connected to the PD end of the laser driver chip 20 , and the other end of the PIN diode 401 is electrically connected to the DC power supply VCC.

Embodiment 2

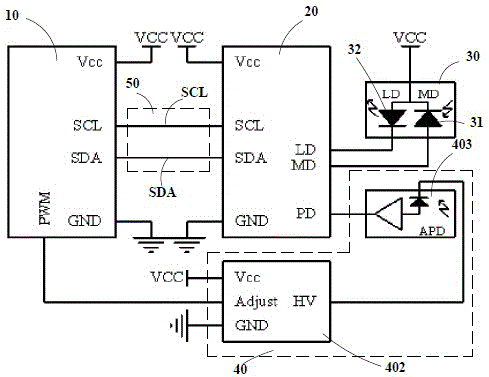

[0028] like figure 2 As shown, the photodiode unit 40 includes a DC / DC unit 402 and an avalanche photodiode 403, the control unit 10 is provided with a pulse width modulation terminal, and the input terminal of the DC / DC unit 402 is electrically connected to the pulse width modulation terminal. The output end of the DC / DC unit 402 is electrically connected to one end of the avalanche photodiode 403, and the other end of the avalanche photodiode 403 is electrically connected to the PD end of the laser driver chip 20; the control unit 10 Outputting different pulse width modulation (PWM) signals according to needs to change the output voltage of the DC / DC unit 402 so that the avalanche photodiode 403 works at an optimal working point.

Embodiment 3

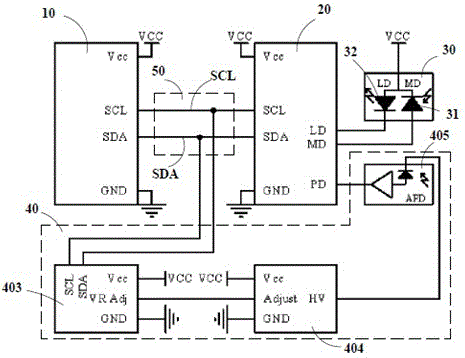

[0030] like image 3 As shown, the photodiode unit 40 includes a digital potentiometer 403, a DC / DC unit 404 and an avalanche photodiode 405, and the input terminals of the digital potentiometer 403 are electrically connected to the bidirectional data line SDA and the clock line SCL respectively, The output end of the digital potentiometer 403 is electrically connected to the input end of the DC / DC unit 404, the output end of the DC / DC unit 404 is electrically connected to one end of the avalanche photodiode 405, and the avalanche photodiode 405 is another One end is electrically connected to the PD end of the laser driver chip 20; the control unit 10 controls the digital potentiometer 403 through the serial data bus 50 to change the resistance value of the digital potentiometer 403, and the digital potentiometer 403 is connected to the DC The / DC unit 404 is connected in series, and the output voltage of the DC / DC unit 404 is changed by changing the resistance of the digital ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com