Sulfur doped titanate nanotube visible light catalyst material and its preparation method

A titanate and nanotube technology, applied in the fields of photocatalysts and material chemistry, can solve the problems that general products and methods do not have suitable structures and methods, and are inconvenient, and achieve improved visible light photocatalytic activity, simple process, and short cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

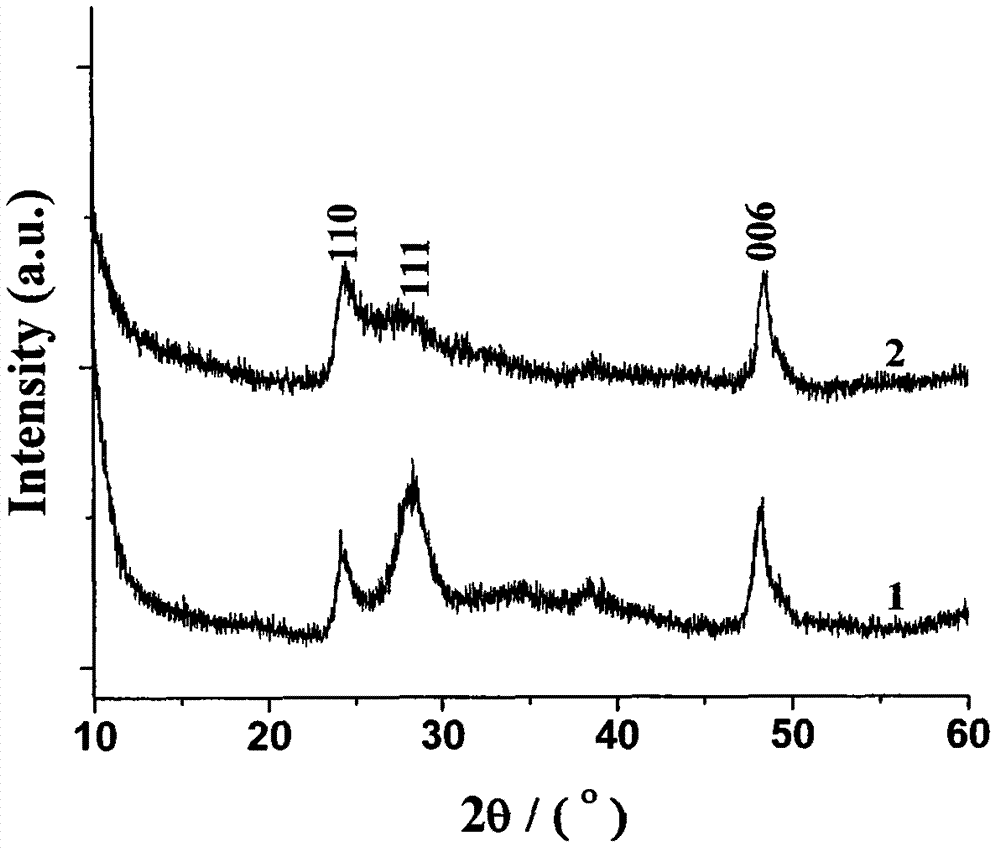

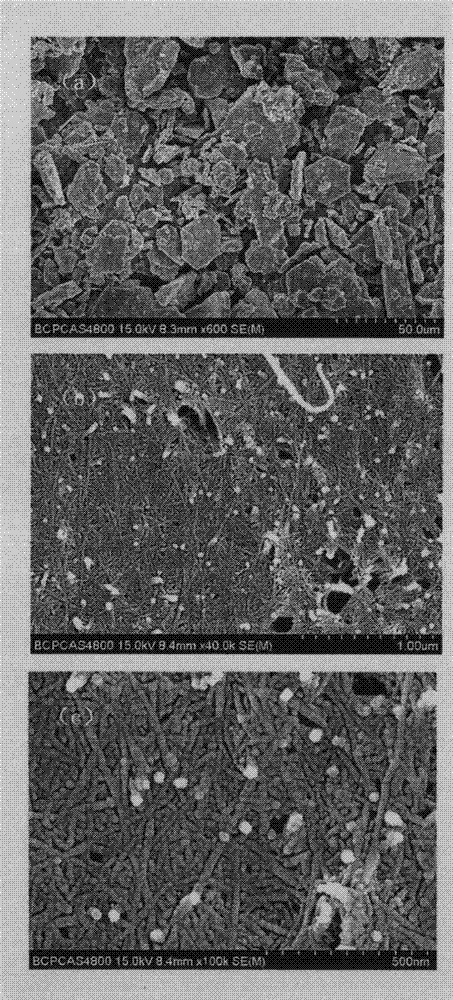

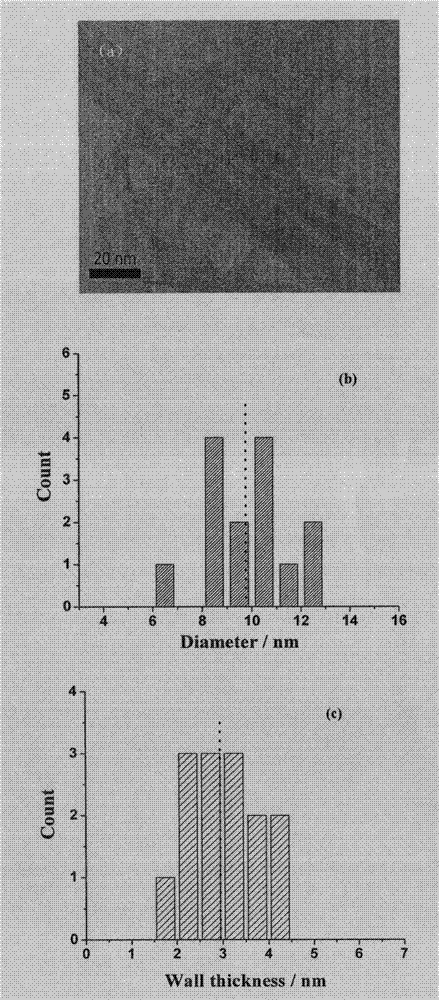

[0037] Example 1 Preparation and method of sulfur-doped titanate nanotube visible light catalyst

[0038] Weigh 4g titanium disulfide (TiS 2 ), dispersed in 100mL of sodium hydroxide (NaOH) solution with a concentration of 10mol / L, mixed thoroughly, then moved into a stainless steel reactor lined with polytetrafluoroethylene, and reacted hydrothermally at 150°C for 24h; the resulting precipitate was filtered and used Pickling with 1mol / L hydrochloric acid solution, then washing with water until neutral, drying at 100°C for 24 hours, and finally obtaining a light gray powder which is sulfur-doped titanate nanotubes.

Embodiment 2

[0039] Example 2 Preparation and method of sulfur-doped titanate nanotube visible light catalyst

[0040] Weigh 2.5g titanium disulfide (TiS 2 ), dispersed in 100mL of sodium hydroxide (NaOH) solution with a concentration of 10mol / L, mixed thoroughly, then moved into a stainless steel reactor lined with polytetrafluoroethylene, and reacted hydrothermally at 150°C for 24h; the resulting precipitate was filtered and used Pickling with 1mol / L hydrochloric acid solution, then washing with water until neutral, drying at 100°C for 24 hours, and finally obtaining a light gray powder which is sulfur-doped titanate nanotubes.

Embodiment 3

[0041] Example 3 Preparation and method of sulfur-doped titanate nanotube visible light catalyst

[0042] Weigh 0.5g titanium disulfide (TiS 2 ), dispersed in 100mL of sodium hydroxide (NaOH) solution with a concentration of 10mol / L, mixed thoroughly, then moved into a stainless steel reactor lined with polytetrafluoroethylene, and reacted hydrothermally at 150°C for 24h; the resulting precipitate was filtered and used Pickling with 1mol / L hydrochloric acid solution, then washing with water until neutral, drying at 100°C for 24 hours, and finally obtaining a light gray powder which is sulfur-doped titanate nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com