A method for purifying terlipressin

A terlipressin and antioxidant technology, which is applied in the field of polypeptide purification, can solve the problems of low purity and yield of terlipressin, cannot meet industrial production, restrict the application of terlipressin, etc., and achieves simple operation. Easy, high yield, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Terlipressin was obtained by liquid phase synthesis.

[0050] Sample treatment: Dissolve the crude peptide with 25% acetonitrile aqueous solution at a concentration of 100g / L, stir to dissolve the sample completely, filter it with a filter membrane, and collect the filtrate. Add the ascorbic acid reagent according to the ratio of 5% of the weight of the crude peptide, and dilute the volume ratio of the acetonitrile in the crude peptide solution to 10% with water for later use.

[0051] purification:

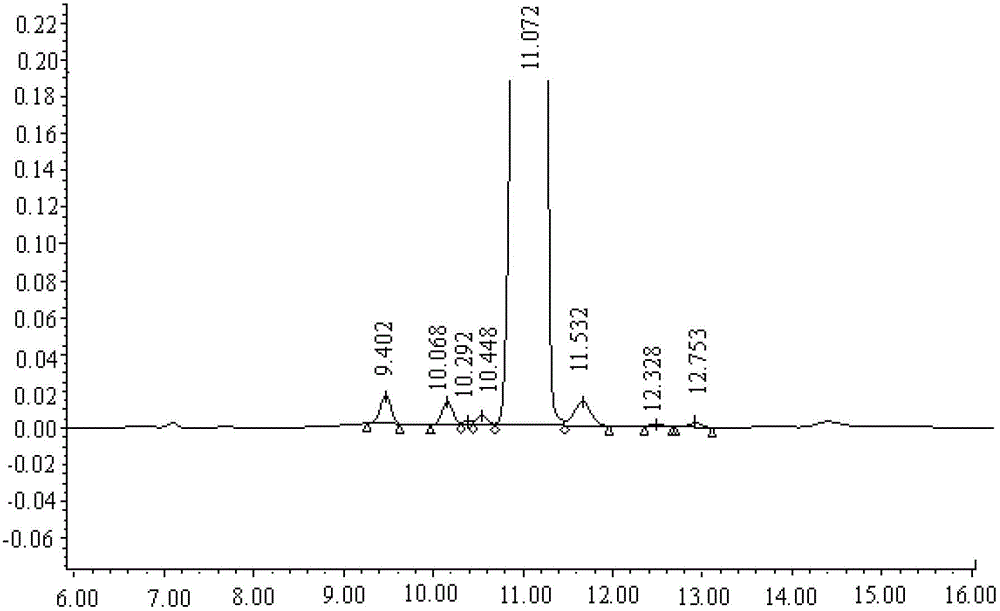

[0052] Purification conditions: chromatographic column: a chromatographic column with octadecylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 5cm×25cm. Mobile phase: Phase A: 0.4% perchloric acid and 0.04% sulfuric acid aqueous solution (v / v), adjust the pH value to 2.8 with 50mM aqueous sodium hydroxide solution; Phase B: acetonitrile, flow rate: 80ml / min, gradient: B%: 10%~40%, detection wavelength: 280nm. The injectio...

Embodiment 2

[0056] Terlipressin was obtained by solid-phase synthesis.

[0057] Sample treatment: Dissolve the crude peptide with 25% methanol aqueous solution at a concentration of 100g / L, stir to dissolve the sample completely, filter it with a filter membrane, and collect the filtrate. Add ascorbic acid reagent at a ratio of 5% of the weight of the crude peptide, and dilute the volume ratio of methanol in the crude peptide solution to 10% with water for use.

[0058] purification:

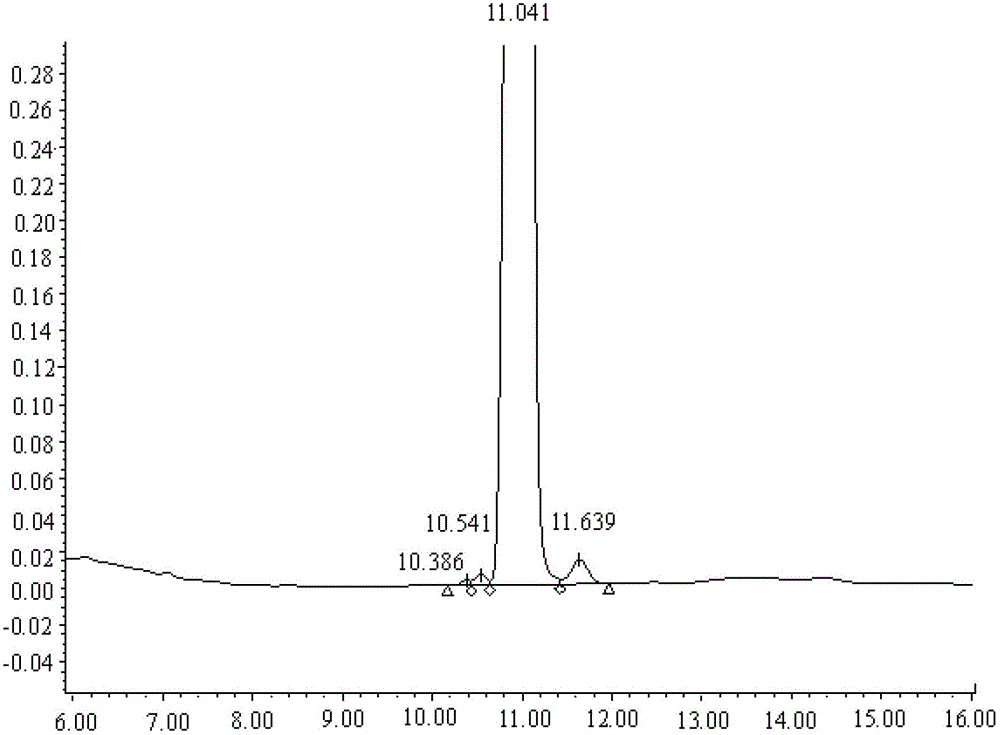

[0059] Purification conditions: chromatographic column: a chromatographic column with octadecylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 15cm×25cm. Mobile phase: A phase: 0.4% perchloric acid and 0.04% sulfuric acid aqueous solution (v / v), adjust the pH value to 2.8 with 50mM sodium hydroxide aqueous solution; B phase: acetonitrile, flow rate: 500ml / min, gradient: B%: 10%~40%, detection wavelength: 280nm. The injection volume is 15-30g.

[0060] Pur...

Embodiment 3

[0063] Terlipressin was obtained by liquid phase synthesis.

[0064] Sample treatment: Dissolve the crude peptide with 25% methanol aqueous solution at a concentration of 100g / L, stir to dissolve the sample completely, filter it with a filter membrane, and collect the filtrate. Add ascorbic acid reagent at a ratio of 5% of the weight of the crude peptide, and dilute the volume ratio of methanol in the crude peptide solution to 10% with water for use.

[0065] purification:

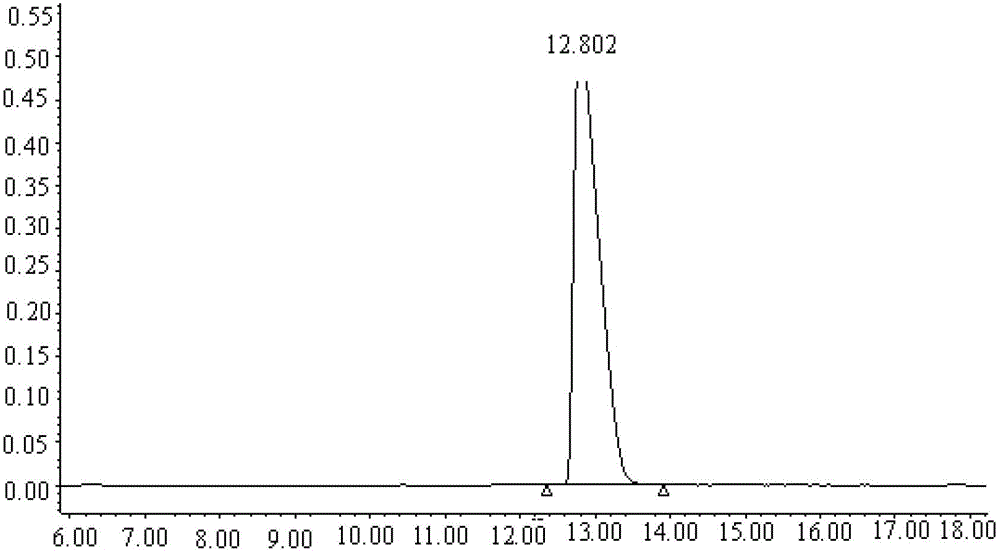

[0066] Purification conditions: chromatographic column: a chromatographic column with octadecylsilane bonded silica gel as the stationary phase, and the diameter and length of the column are: 30cm×25cm. Mobile phase: Phase A: 0.4% perchloric acid and 0.04% sulfuric acid aqueous solution (v / v), adjust the pH value to 2.8 with 50mM aqueous sodium hydroxide solution; Phase B: acetonitrile, flow rate: 3000ml / min, gradient: B%: 10%~40%, detection wavelength: 280nm. The injection volume is 120g.

[0067] Pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com