Pd/TiO2atCNT catalyst and preparation method thereof

A technology of catalyst and catalytic activity, which is applied in the field of Pd/TiO2CNT catalyst and its preparation, can solve the problems of low electrical conductivity and insignificant improvement of catalyst performance, and achieve the effects of improving electrocatalytic activity, enhancing corrosion resistance, and reducing degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

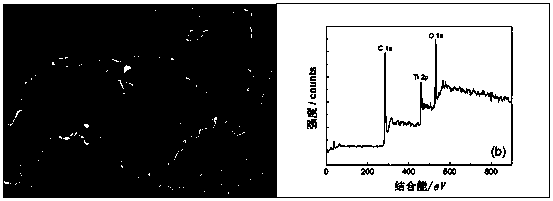

Embodiment 1

[0022] 1) Place the carbon nanotubes in a mixed acid of concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1), and conduct an ultrasonic reaction at a constant temperature of 80 °C for 8 h, wash and filter with deionized water, until the pH of the filtrate is reached It is neutral and dried at low temperature to obtain functionalized carbon nanotube materials;

[0023] 2) Put the titanium dioxide powder in a muffle furnace, calcined at 500 °C, after cooling, disperse in 0.2 M nitric acid solution, react for 3 h under stirring conditions, wash and filter with deionized water, until the pH value of the filtrate Be neutral, dry at 60 ° C, obtain the titanium dioxide material after modification;

[0024] 3) Disperse the titanium dioxide powder obtained in step 2) in deionized water, stir rapidly for 10 min, then add the carbon nanotube material obtained in step 1), continue stirring for 20 min, ...

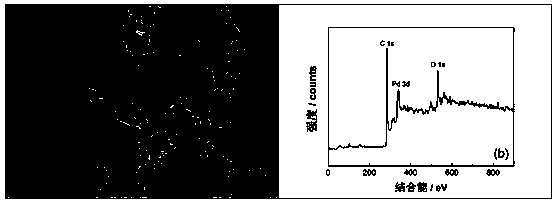

example example 2

[0028] 1) Place the carbon nanotubes in a mixed acid of concentrated sulfuric acid and concentrated nitric acid, react with ultrasonic at a constant temperature of 90 °C for 7 h, wash and filter with deionized water until the pH of the filtrate is neutral, and dry at low temperature to obtain functionalized carbon nanotubes tube material;

[0029] 2) Put the titanium dioxide powder in a muffle furnace, calcined at 600 °C, after cooling, disperse in 0.4 M nitric acid solution, react for 2 h under stirring conditions, wash and filter with deionized water, until the pH value of the filtrate Be neutral, dry at 70 ° C to obtain the modified titanium dioxide material;

[0030] 3) Disperse the titanium dioxide powder obtained in step 2) in deionized water, stir rapidly for 13 minutes, then add the carbon nanotube material obtained in step 1), continue stirring for 25 minutes, then slowly add 18 ml of isopropanol, continue Stir for 30 min, then add 6 ml of ethylene glycol, continue t...

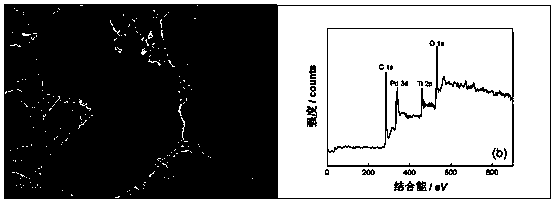

example example 3

[0034]1) Put the carbon nanotubes in the mixed acid of concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1), 100 °C constant temperature ultrasonic reaction for 8 h, wash and filter with deionized water, until the pH value of the filtrate It is neutral and dried at low temperature to obtain functionalized carbon nanotube materials;

[0035] 2) Put titanium dioxide powder in a muffle furnace, calcined at 600 °C, after cooling, disperse in 0.6 M nitric acid solution, react for 1 h under stirring conditions, wash and filter with deionized water, until the pH value of the filtrate Be neutral, dry at 80 ° C, obtain the titanium dioxide material after the modification;

[0036] 3) Disperse the titanium dioxide powder obtained in step 2) in deionized water, stir rapidly for 15 minutes, then add the carbon nanotube material obtained in step 1), continue stirring for 30 minutes, then slowly add 25 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com