Fe-Co bimetal multiphase Fenton-like catalyst taking modified sepiolite as carrier and preparation method thereof

A sepiolite and catalyst technology, applied in the field of catalyst preparation, can solve the problems of iron ion secondary pollution, narrow pH value range, low hydrogen peroxide utilization rate, etc., achieve long-lasting and efficient removal, low price and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

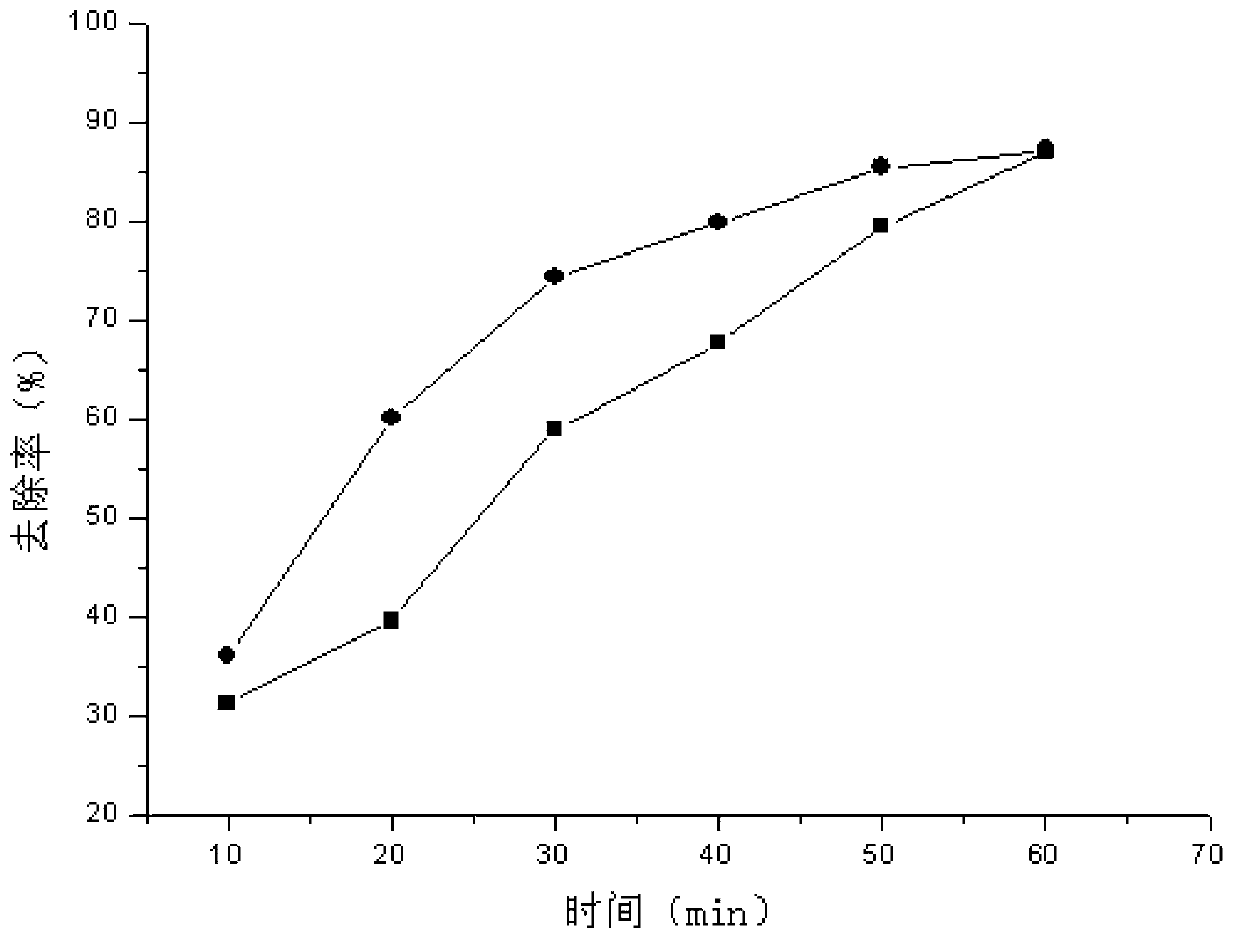

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: In this embodiment, the preparation method of Fe-Co bimetallic heterogeneous Fenton-like catalyst with modified sepiolite as the carrier is realized according to the following steps:

[0015] 1. Add 100-150 mesh sepiolite powder into sulfuric acid with a concentration of 0.5mol / L according to the ratio of solid-liquid ratio of 1:10 for acidification, stir at a speed of 120-130r / min for 3-4 hours, and use Wash with ionic water until neutral, filter, and then activate at 105°C for 2-3 hours to obtain modified sepiolite;

[0016] 2. Put 2.02~8.08g of Fe(NO 3 ) 3 9H 2 O and 0.87-4.36g of Co(NO 3 ) 3 ·6H 2 O was added to 100mL deionized water to obtain a mixed solution of ferric nitrate and cobalt nitrate, and then 1.5-6g of urea was added to obtain a mixed solution;

[0017] 3. Pour the mixed solution into a 250mL glass Erlenmeyer flask with a silica gel stopper containing 4g of modified sepiolite, then place it in a water bath and heat it to 10...

Embodiment

[0019] The preparation method of the Fe-Co bimetallic heterogeneous Fenton-like catalyst with modified sepiolite as a carrier is realized in the following steps:

[0020] 1. Add 150-mesh sepiolite powder into sulfuric acid with a concentration of 0.5mol / L for acidification according to the ratio of solid-liquid ratio of 1:10, stir at a speed of 130r / min for 3 hours, and wash with deionized water until neutral , filtered, and then activated at 105°C for 3 hours to obtain modified sepiolite;

[0021] Two, 6.06g of Fe(NO 3 ) 3 9H 2 O and 1.45g of Co(NO 3 ) 3 ·6H 2 O was added to 100mL deionized water to obtain a mixed solution of ferric nitrate and cobalt nitrate, and then 3g of urea was added to obtain a mixed solution;

[0022] 3. Pour the mixed solution into a 250mL glass Erlenmeyer flask with a silica gel stopper containing 4g of modified sepiolite, then place it in a water bath and heat it to 100°C, stir for 2 hours, and cool and age for 2 hours to obtain a precipitate...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 120 mesh sepiolite powder is added into sulfuric acid with a concentration of 0.5 mol / L according to the ratio of solid to liquid ratio of 1:10 for acidification . Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com