Method for comprehensively recovering lead and silver from lead slag

A lead slag, lead-silver technology, applied in solid separation, flotation and other directions, can solve problems such as lead slag flotation for lead that have not yet been found, and achieve the effects of improving comprehensive recovery capacity, reducing resource waste and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

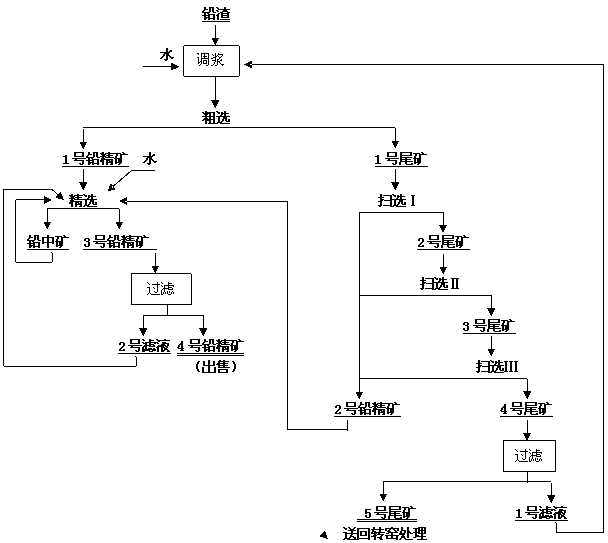

Method used

Image

Examples

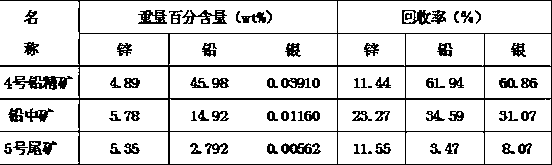

Embodiment 1

[0022] Produced by Yunnan Luoping Zinc Electric Co., Ltd. Electric Zinc Factory, the weight percentage of its main components is lead 14.98wt%, silver 0.0128wt%, zinc 8.45wt%, moisture 27.12wt% lead slag 5000g, water slurry , control the liquid-solid ratio to 1.8:1, add sodium carbonate solid at the same time, control the pH=5.0-5.4 of the solution, stir for 25min; add 66.00g of sodium sulfide and make sodium sulfide into a 10wt% aqueous solution, stir for 15min, then add 6.50 g zinc sulfate and prepare zinc sulfate as 10wt% aqueous solution to inhibit zinc, stir for 5min, add 1.50g butylxanthate and prepare butylxanthate as 10wt% aqueous solution, stir for 2min, add 1.50g butylamine black medicine And prepare the butylamine black medicine as a 10wt% aqueous solution, stir for 2 minutes, then add 1.50g of ethyl thiazolin and prepare a 10wt% aqueous solution of butylamine, stir for 2 minutes, open the inflation valve, scrape and bubble for 8 minutes, and carry out rough separati...

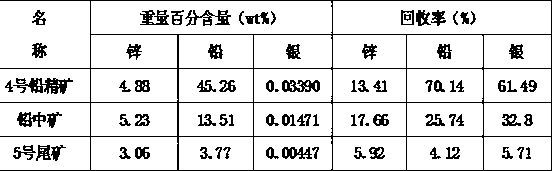

Embodiment 2

[0031] Produced by Yunnan Luoping Zinc Electric Co., Ltd. Electric Zinc Factory, the weight percentage of its main components is lead 15.02wt%, silver 0.013wt%, zinc 8.65wt%, moisture 27.42wt% lead slag 7000g, water slurry , control the liquid-solid ratio to 2.5:1, add solid sodium carbonate at the same time, control the pH of the solution to 5.0-5.4, and stir for 30 minutes. Add 180.00g sodium sulfide and prepare sodium sulfide as a 10wt% aqueous solution, stir for 20min, then add 27.00g zinc sulfate and prepare zinc sulfate as a 10wt% aqueous solution to inhibit zinc, stir for 6min, add 5.50g butyl xanthate and Butyl xanthate is prepared as a 10wt% aqueous solution, stirred for 3min, 5.50g butylamine black medicine is added and the butylamine black medicine is prepared as a 10wt% aqueous solution, stirred for 3min, then 5.50g ethyl thiamine is added and ethyl sulfide is added. Nitrogen was prepared as a 10wt% aqueous solution, stirred for 3 minutes, opened the inflation valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com