Preparation method of catalyst for producing synthetic gas by methane and carbon dioxide reformation

A carbon dioxide and synthesis gas technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, bulk chemical production, etc., can solve the problems of poor stability and achieve high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

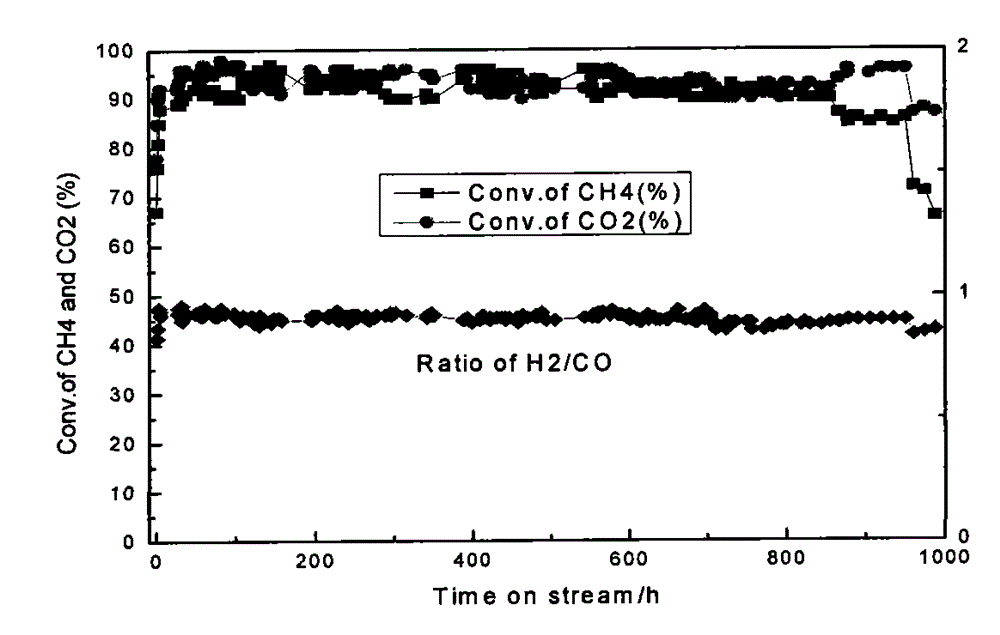

Examples

Embodiment approach 1

[0016] Weigh 0.1-50g of nickel nitrate, dissolve it in 10-100ml of deionized water, stir at a constant temperature for 10-30min at 60-90°C, then add 0.1-50g of additives (ammonium molybdate, cobalt nitrate, oxychloride zirconium as an example), heating to fully dissolve the two, evaporate the water, dry in an oven at 110°C for 24h, place the dried solid powder in a muffle furnace, and bake in an air atmosphere at 300-900°C for 3-10h. The calcined catalyst precursor is pressed into tablets and sieved, and the precursor of 40-60 mesh is selected and placed in a fixed-bed quartz tube reactor, and the temperature is programmed to rise to 600-1000°C in a 1:2 ratio of H2:N2 atmosphere. After 0.5-15 hours, the catalyst for the production of synthesis gas by the reforming of methane and carbon dioxide in a fixed bed is obtained, and the methane and carbon dioxide gas in the ratio of 1:1 is fed into the catalyst for activity evaluation. The evaluation results are shown in Table 1.

[0...

Embodiment approach 2

[0021] Weigh 0.1-50g of nickel nitrate, dissolve it in 10-100ml of deionized water, stir at a constant temperature for 10-30min at 60-90°C, then add 0.1-50g of additives (ammonium molybdate, cobalt nitrate, oxychloride Zirconium as an example), stirring at constant temperature for 10-30min to fully dissolve the two, then add 1-50g carrier (take SBA-15 or MEM molecular sieve as an example) under stirring, stir at constant temperature for 10-12 hours, let it stand for 24h, and place it at 60- Evaporate water at 90°C and dry in an oven at 110°C for 24 hours. Other steps and conditions are the same as in Embodiment 1. The evaluation results are shown in Table 2.

[0022] Table 2. Evaluation results of Embodiment 2

[0023] temperature (k)

Embodiment approach 3

[0025] Weigh 0.1-50g of nickel nitrate and 0.1-50g of ammonium molybdate and dissolve them in 10-100ml of deionized water, and stir at a constant temperature for 10-30min at 60-90°C, then add 1-50g of carrier (based on SBA-15 or MEM molecular sieves as an example), stirring at constant temperature for 10-12 hours, standing for 24 hours, evaporating water at 60-90°C, drying in an oven at 110°C for 24 hours, other steps, conditions are the same as in Embodiment 1. The evaluation results are shown in Table 3.

[0026] Table 3. Evaluation results of Embodiment 3

[0027] temperature (k)

[0028] 873

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com