Method for preparing nitrogen-doped graphene by utilizing plasma sputtering

A technology of nitrogen-doped graphene and plasma sputtering is applied in the field of nanomaterial catalytic doping, which can solve the problems of low synthesis efficiency and quality, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

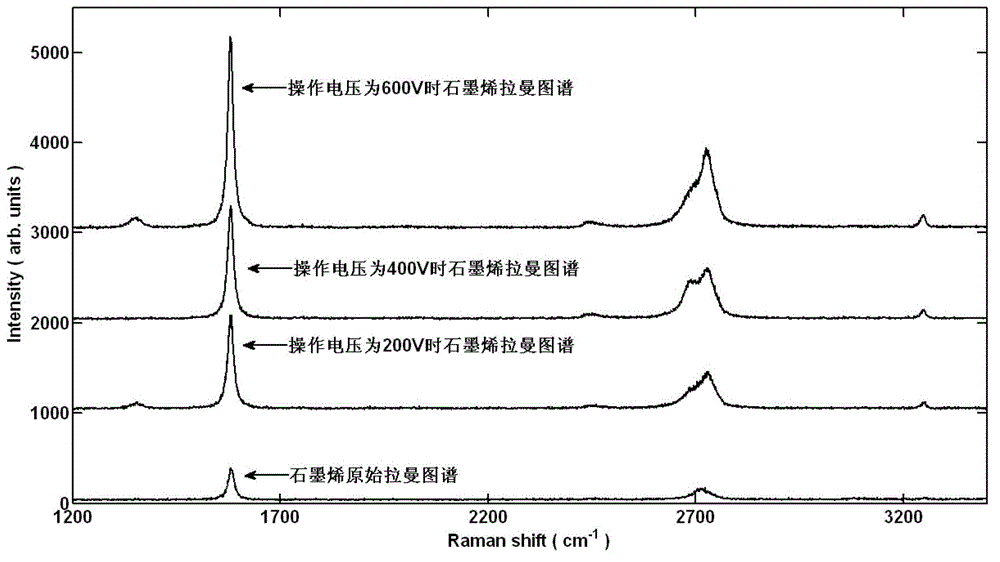

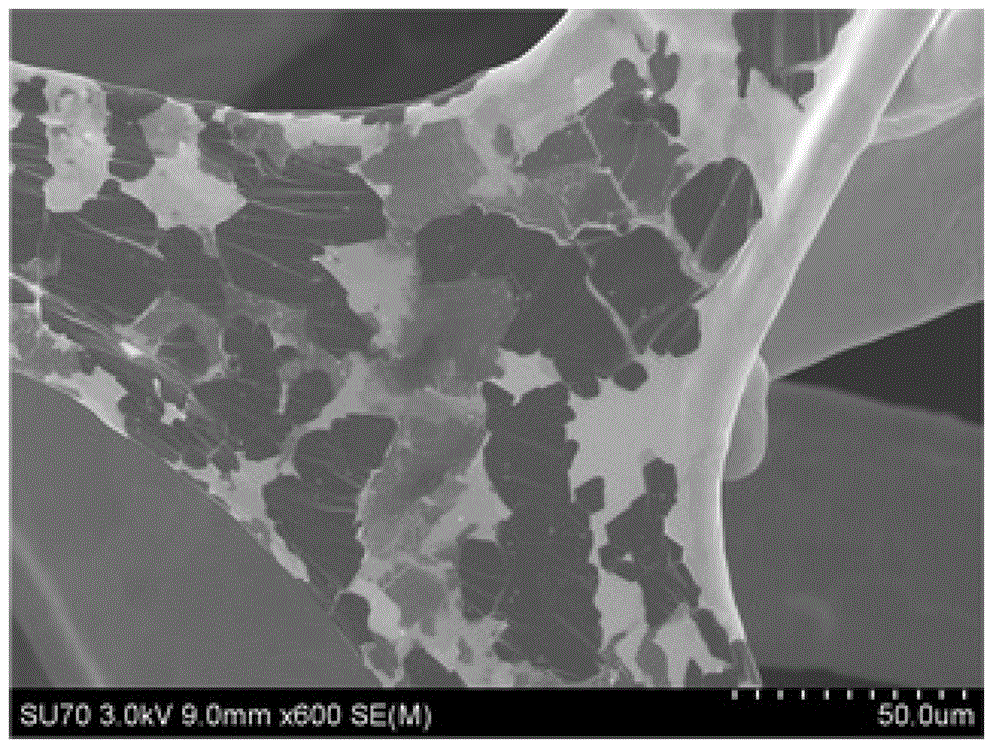

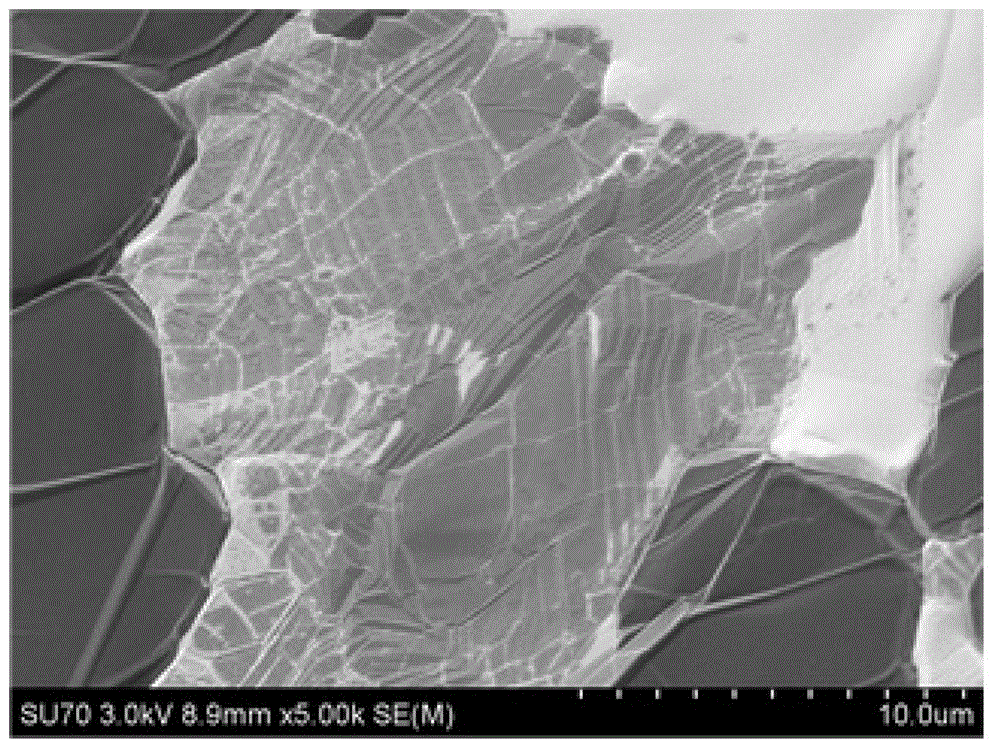

[0023] Example 1: Experimental operation of nitrogen doping with graphene prepared from nickel foil and operating voltage of 600V.

[0024] First, the nickel foil was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the reaction substrate was blown dry with high-purity nitrogen gas and left to stand for 5 minutes; then the nickel foil was put into the CVD device, and a flow rate of 15 sccm was introduced control the reaction furnace to rise to 850°C within 30 minutes, keep the CVD device running at a high temperature for 60 minutes, and feed 75 sccm of methane into the CVD device; then control the temperature of the CVD device to drop to normal temperature within 5 minutes, and take out the grown The nickel foil of graphene is also put into the reaction chamber of plasma sputtering device, utilizes vacuum pump to control the vacuum environment of reaction chamber below 5mTorr, and feeds the ammonia gas of 5sccm flow in reaction cha...

Embodiment 2

[0025] Example 2: Experimental operation of nitrogen doping with graphene prepared from nickel foil and operating voltage of 400V.

[0026] First, the nickel foil was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the reaction substrate was blown dry with high-purity nitrogen gas and allowed to stand for 10 minutes; then the nickel foil was put into the CVD device, and a flow rate of 15 sccm was introduced. control the reaction furnace to rise to 850°C within 30 minutes, keep the CVD device running at a high temperature for 60 minutes, and feed 75 sccm of methane into the CVD device; then control the temperature of the CVD device to drop to normal temperature within 5 minutes, and take out the grown The nickel foil of graphene is also put into the reaction chamber of plasma sputtering device, utilizes vacuum pump to control the vacuum environment of reaction chamber below 5mTorr, and feeds the ammonia gas of 5sccm flow in reactio...

Embodiment 3

[0027] Embodiment 3: Nitrogen-doped experimental operation carried out using graphene prepared from nickel foil with an operating voltage of 200V.

[0028] First, the nickel foil was ultrasonically cleaned in deionized water, acetone and ethanol for 30 minutes respectively, and the reaction substrate was blown dry with high-purity nitrogen gas and left to stand for 5 minutes; then the nickel foil was put into the CVD device, and a flow rate of 15 sccm was introduced control the reaction furnace to rise to 850°C within 30 minutes, keep the CVD device running at a high temperature for 60 minutes, and feed 75 sccm of methane into the CVD device; then control the temperature of the CVD device to drop to normal temperature within 5 minutes, and take out the grown The nickel foil of graphene is also put into the reaction chamber of plasma sputtering device, utilizes vacuum pump to control the vacuum environment of reaction chamber below 5mTorr, and feeds the ammonia gas of 5sccm flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com