Method and device for purifying graphite

A technology of graphite and furnace body, which is applied in the field of high-purity purification of natural graphite, can solve the problems of huge investment, expensive equipment, and large loss of graphite, and achieve the effects of high heat utilization rate, simple device and rapid temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

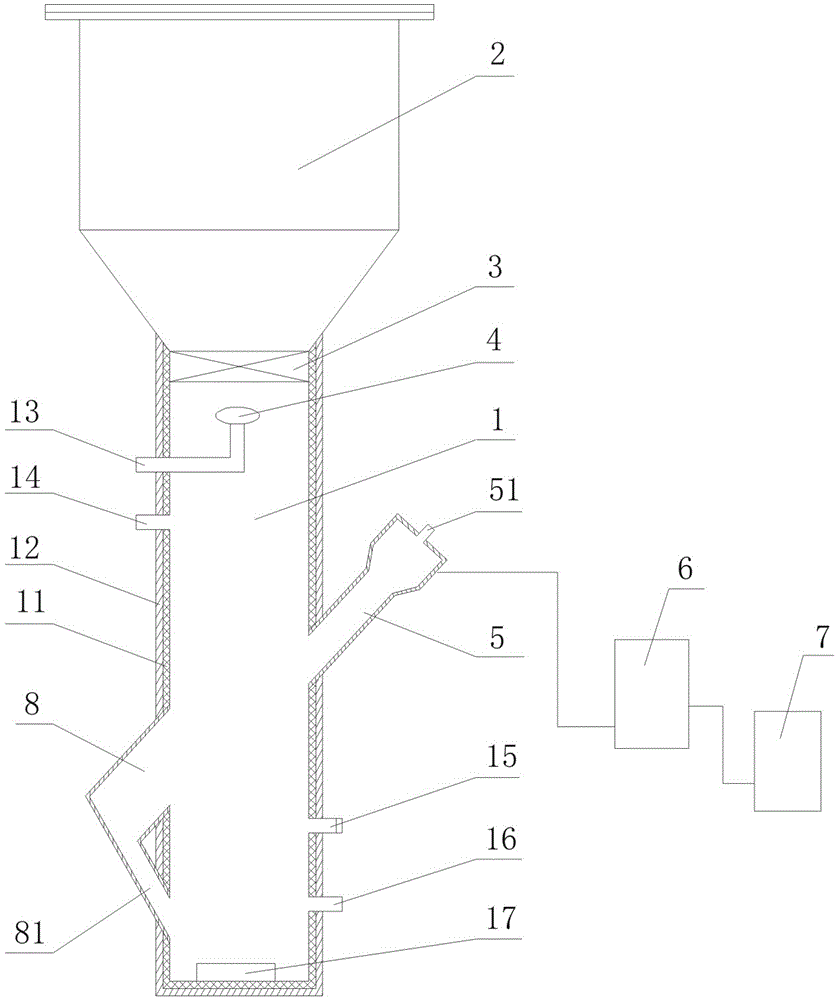

[0029] Embodiment 1, refer to figure 1 as shown,

[0030] A method for purifying graphite, it comprises the steps:

[0031] 1) Preparation of the device for purifying graphite;

[0032]2) Isolate the air: close the flash valve 3, the intake valve on the jet pipe 13, the tail gas discharge port 14 and the protective gas inlet 15, and load graphite raw materials into the hopper 2 (in order to improve the purification efficiency, generally use carbon mass Graphite concentrate with content ≥ 90% as raw material), connect the vacuum pump to the vacuum connection port 16, start the vacuum pump to pump the furnace body 1 into a vacuum state (vacuum degree is 0.01 ~ 0.05MPa), after the vacuum is completed, go to The protective gas inlet 15 is connected to the protective gas to restore the pressure in the furnace body 1 to atmospheric pressure, and the protective gas inlet 15 is closed after completion; in order to ensure the non-oxidizing atmosphere in the furnace, it can be evacuat...

Embodiment 2

[0045] It is basically the same as Example 1, the difference is: in order to obtain higher purity graphite, repeat steps 2) to 4) to perform a purification [return the purified graphite to the hopper 2 and enter the furnace body 1 again, that is After a second purification]. Graphite with an initial carbon mass content of 90% and a particle size of 100 mesh has a carbon mass content of 98.7% after the first purification; and a carbon mass content of 99.5% after the second purification.

Embodiment 3

[0047] It is basically the same as Example 1, except that in order to obtain graphite with higher purity, repeat steps 2) to 4) for secondary purification [return the purified graphite to the hopper 2 and enter the furnace body 1 again, Namely after the third purification]. Graphite with an initial carbon mass content of 90% and a particle size of 100 mesh has a carbon mass content of 98.7% after the first purification; a carbon mass content of 99.5% after the second purification; and a carbon content of 99.9% after the third purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com