Biologic graphite oxide obtained by nutrifying bacteria and preparation method for biologic graphite oxide

A technology of biological oxidation and nitrifying bacteria, applied in the direction of graphite, etc., can solve problems such as defects, carbon skeleton lattice distortion and distortion, carbon skeleton lattice distortion and distortion at the atomic level, and achieve good industrial application prospects and value. Preparation The process is green and pollution-free, and the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

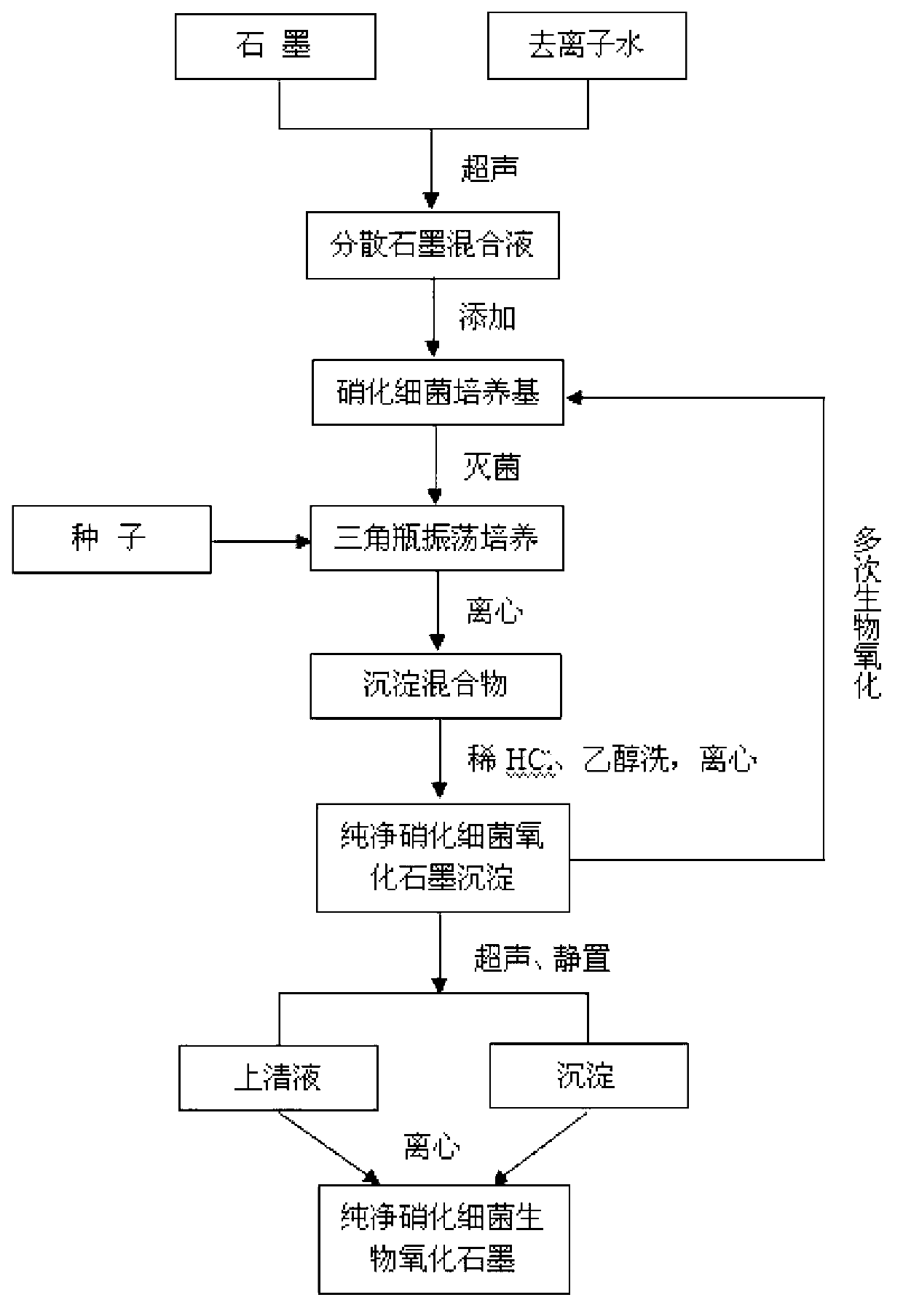

[0029] Embodiment 1: A preparation method of bio-oxidized graphite according to the present invention comprises the following steps: The first step is graphite pretreatment. Add 1.0g of graphite in a 250mL conical flask, add deionized water to 100g in a 250mL conical flask, and in a 250W ultrasonic cleaning machine, perform ultrasonic treatment at room temperature for 2 hours to obtain a graphite dispersion with good dispersion properties;

[0030] The second step, prepare 1.0L of nitrifying bacteria liquid culture medium, add 1% graphite dispersion liquid that 15g first step is dispersed in the substratum, sub-pack in 4 1.0L conical flasks, and the liquid volume of every bottle is 250mL, so The graphite concentration is 0.15mg / mL. Among them, 1.0L of nitrifying bacteria liquid culture medium includes (NH 4 ) 2 SO 4 0.24g, sodium succinate 2.81g, Vickers salt solution 50mL (Vickers salt solution composition, content: K 2 HPO 4 ·3H 2 O 6.5g / L, MgSO 4 ·7H 2 O 2.5g / L, Na...

Embodiment 2

[0035] Embodiment 2: the preparation method of a kind of nitrifying bacteria biological graphite oxide of the present invention, comprises the following steps:

[0036] The first step is graphite pretreatment. Add 2.0g of graphite in a 250mL conical flask, add deionized water to 100g in the conical flask, put it in a 250W ultrasonic cleaning machine, and perform ultrasonic treatment for 4 hours at room temperature to obtain a graphite mixed dispersion with better dispersion properties;

[0037] The second step is to prepare 1.0L of nitrifying bacteria liquid culture medium, add 10g of the graphite mixed solution dispersed in the first step to the culture medium, and distribute it to four 1.0L conical flasks, the liquid volume of each bottle is 250mL, and the graphite contained The concentration is 0.2 mg / mL. Among them, 1.0L of nitrifying bacteria liquid culture medium includes (NH 4 ) 2 SO 4 0.24g, sodium succinate 2.81g, Vickers salt solution 50mL (the content is the s...

Embodiment 3

[0040] Embodiment 3: a kind of preparation method of biological graphite oxide of the present invention comprises the following steps:

[0041] The first step is graphite pretreatment. Add 0.5g of graphite in a 250mL conical flask, add deionized water to 100g in the conical flask, put it in a 250W ultrasonic cleaning machine, and perform ultrasonic treatment at room temperature for 1 hour to obtain a graphite dispersion with good dispersion properties;

[0042] The second step is to prepare 1.0L of nitrifying bacteria liquid culture medium, add 10g of the graphite mixed solution dispersed in the first step to the culture medium, and distribute it to four 1.0L conical flasks, the liquid volume of each bottle is 250mL, and the graphite contained The concentration is 0.05mg / mL. Among them, 1.0L of 9K liquid medium includes (NH 4 ) 2 SO 4 0.24g, sodium succinate 2.81g, Vickers salt solution 50mL (same as the second step of Example 1), pH 7.0, high pressure steam moist heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com