Production method of water-soluble microbe multi-element solid fertilizer

A technology of solid fertilizers and production methods, applied in the direction of fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of limiting the output and quality of agricultural products, low effective utilization rate of fertilizers, and low fertilizer utilization efficiency, so as to improve the quality of agricultural products and improve the quality of fertilizers. Utilization rate, effect of improving fertilizer efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

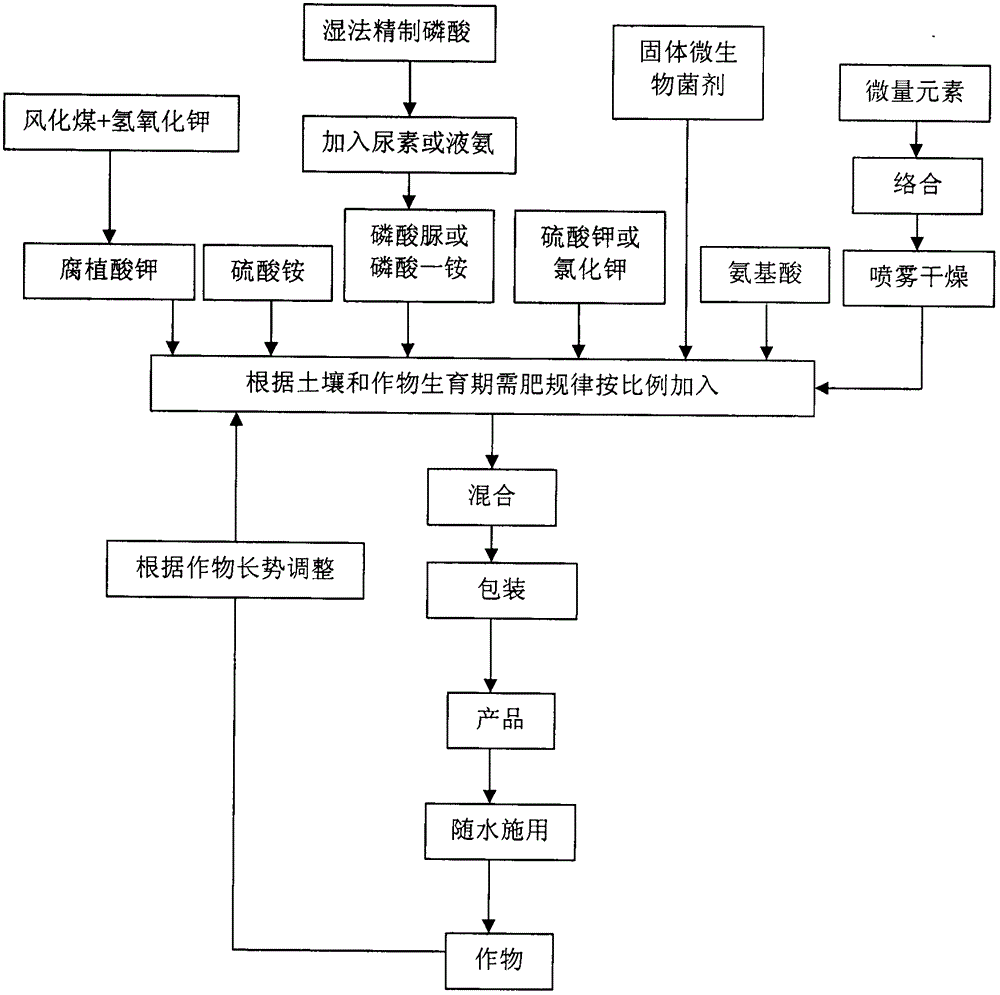

[0037] Referring to Figure 1, by weight percentage, 25 parts of component A potassium humate (water solubility ≥ 90%, humic acid ≥ 75%), 35 parts of component B ammonium sulfate containing 21% nitrogen, 0 phosphorus, and potassium 0, 13 parts Component C monoammonium phosphate contains 12% nitrogen, 60% phosphorus, 0 potassium, 4.7 parts Component D potassium sulfate contains 0 nitrogen, 0 phosphorus, 50% potassium and 0.3 parts Component E microbial agent, 20 parts of component F amino acid, 2 parts of component G complex fertilizer (the ratio of Zn, B, Mn, Fe, Cu, Mo is 1:0.5:0.3:0.2:0.1:0.05) Mix evenly to get organic matter 25%, N12%, P2 o 5 8%, K 2 o 5 %, trace elements (Zn+B+Mn+Fe+Cu+Mo) 0.5% water-soluble bio-multivariate solid fertilizer, used for drip irrigation of cotton seedling stage - flowering and boll stage fertilization with water.

[0038] The component E is preferably a solid bacillus inoculant. Its quality requirements: the number of effective viable bac...

Embodiment 2

[0044] Compared with Example 1, the difference is that by weight percentage, 25 parts of component A potassium humate (water-soluble ≥ 90%, humic acid ≥ 75%), 25 parts of component B ammonium sulfate containing 21% nitrogen, containing Phosphorus is 0, potassium is 0, 10 parts of component C monoammonium phosphate contains 12% nitrogen, phosphorus is 60%, potassium is 0, and 17 parts of component D potassium sulfate is 0 nitrogen, phosphorus is 0, and Potassium 50% and 1 part of component E microbial agent, 20 parts of component F amino acid, 2 parts of component G complex fertilizer (the ratio of Zn, B, Mn, Fe, Cu, Mo is 1: 0.5: 0.3: 0.2:0.1:0.05) and mix evenly to obtain 25% organic matter, N9.5%, P 2 o 5 6%, K 2 O11.5%, trace elements (Zn+B+Mn+Fe+Cu+Mo) 0.5% water-soluble microbial multi-component solid fertilizer, used for fertilization with water at the initial flowering stage of drip irrigation tomato.

[0045] The component G is mainly prepared by the following proce...

Embodiment 3

[0048] Compared with Example 1, the difference is: by weight percentage, 25 parts of component A potassium humate (water-soluble ≥ 90%, humic acid ≥ 75%), 15 parts of component B ammonium sulfate containing nitrogen 21%, Phosphorus is 0, potassium is 0, 10 parts of component C monoammonium phosphate contains 12% nitrogen, phosphorus is 60%, potassium is 0, 28 parts of component D potassium sulfate is 0 nitrogen, phosphorus is 0, Potassium-containing 50% and 0.5 part of component E microbial bacterial agent, 20 parts of component F amino acid, 2 parts of component G complex micro-fertilizer (the ratio of Zn, B, Mn, Fe, Cu, Mo is 1: 0.5: 0.3 : 0.2: 0.1: 0.05) mixed evenly to obtain 25% organic matter, N7.5%, P 2 o 5 6%, K 2 O 16.5%, microelement (Zn+B+Mn+Fe+Cu+Mo) 0.5% water-soluble microbial multi-component solid fertilizer, used for fertilization with water during drip irrigation of watermelon fruit expansion.

[0049] The component G is mainly prepared by the following pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com