Purification method for high-purity organic solvent normal propyl alcohol

A technology of organic solvent and purification method, applied in the field of purification of high-purity organic solvent n-propanol, can solve the problems of difficult removal, no published patent documents, low amount of impurities, etc., to reduce energy consumption, save manpower, and operate stably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of purification method of high-purity organic solvent n-propanol, the steps are as follows:

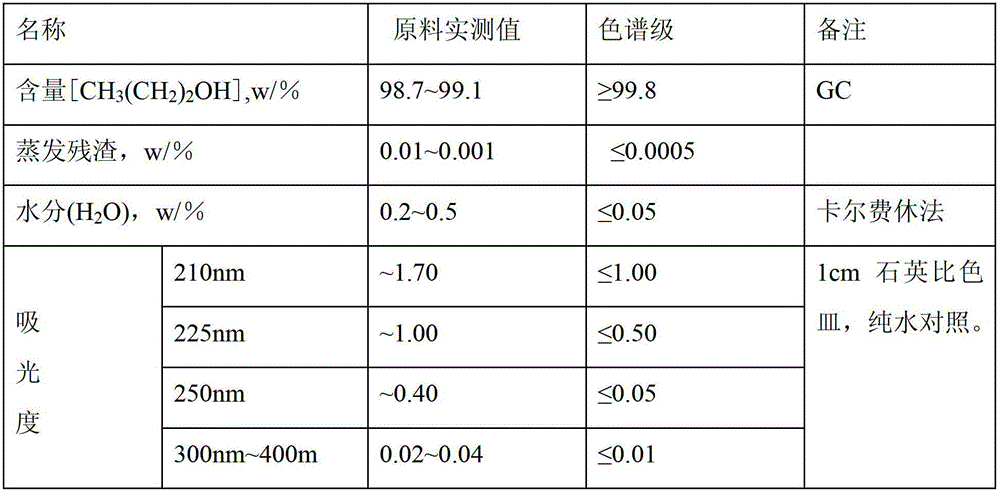

[0021] ⑴ Raise the raw material n-propanol (content is about 99.1%) above the adsorption column, and the n-propanol raw material flows through the adsorption column at a speed of 40mL / min. The adsorption column is 1.6M high and 4.2cm in diameter. The amount of activated carbon adsorbent inside is 4 / 5 of the column height, and the particle size of activated carbon is 0.4mm~0.8mm. In the adsorption column, n-propanol is in full contact with the activated carbon adsorbent to absorb organic impurities with high ultraviolet rays. After the adsorption effluent test is nearly qualified (see Table 1 for specific technical index requirements), enter the next step to further purify and remove the fraction before adsorption.

[0022] (2) Put the n-propanol flowing out of the above-mentioned adsorption column into the drying column, the column height is 1.6M, and the diameter is 4....

Embodiment 2

[0026] A kind of purification method of high-purity organic solvent n-propanol, the steps are as follows:

[0027] ⑴ Raise the raw material n-propanol (content is about 99.1%) to the top of the adsorption column, and the n-propanol raw material is adsorbed at a speed of 100mL / min. The adsorption column is 1.6M high and 4.2cm in diameter. The amount of activated carbon adsorbent inside is 4 / 5 of the column height, and the particle size of activated carbon is 0.4mm~0.8mm. After the adsorption liquid is nearly qualified, enter the next step to further purify and remove the pre-adsorption fraction with high impurities;

[0028] (2) Put the effluent from the above-mentioned adsorption column into the drying column, the tower height is 1.6M, and the diameter is 4.2cm. Fill it with calcium hydride, and measure the water content of n-propanol after drying. The water content is controlled at ≤0.05%. After the water content is qualified, enter the next step Operation; when the moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com