Method for separating beta-lactoglobulin from raw milk

The technology of lactoglobulin and raw milk is applied in the field of separation and purification of beta-lactoglobulin, which can solve the problems of complicated instrument, small processing capacity and high preparation cost, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

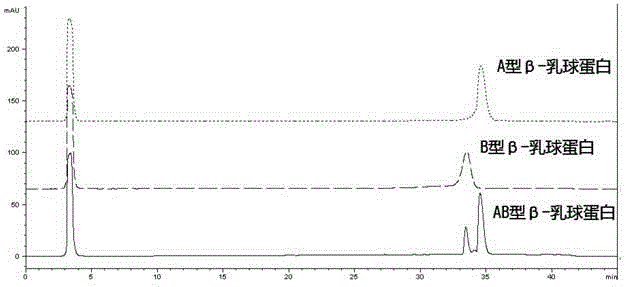

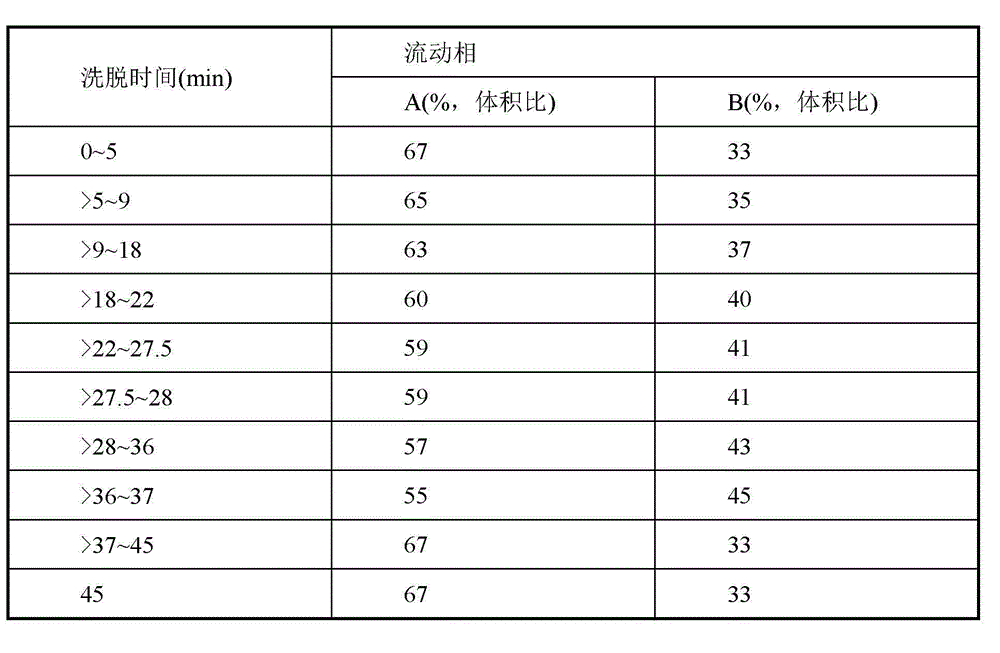

Image

Examples

Embodiment 1

[0033] Embodiment 1. A method for isolating β-lactoglobulin from raw milk, using 1000ml of fresh cow's milk as a raw material; following steps in sequence:

[0034] 1) Fresh milk is centrifuged at 4000g at 4°C for 30 minutes, filtered through 4 layers of skimmed gauze to remove milk fat, and the first filtrate obtained is collected;

[0035] 2) Adjust the pH of the first filtrate to 4.6 with 1 M hydrochloric acid, and let it stand at room temperature for 30 minutes; obtain the first filtrate after treatment;

[0036] 3) Centrifuge the filtrate for the first time after treatment at 4°C, 5000g for 20 min, and filter it with 4 layers of degreasing gauze. gauze filter), to obtain the secondary filtrate;

[0037] 4) Adjust the pH of the secondary filtrate to 2.0 with 1M hydrochloric acid to obtain the treated secondary filtrate; record the volume of the treated secondary filtrate;

[0038] 5) First add 70g of sodium chloride to the secondary filtrate according to the dosage ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com