Preparation method of temperature and pH sensitive shell cross-linked polymeric micelle

A cross-linked polymer and sensitive technology, which is applied in the direction of non-active ingredient medical preparations, drug combinations, pharmaceutical formulations, etc., can solve the problem of strict polymer block ratio, uneven micelle size, and low critical Concentration and other issues, to achieve excellent drug loading performance, easy operation, good environmental protection and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

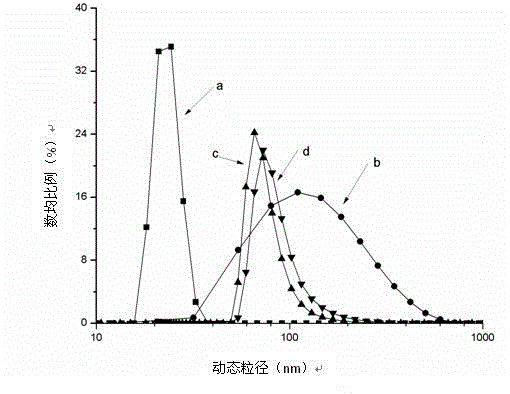

Method used

Image

Examples

Embodiment 1

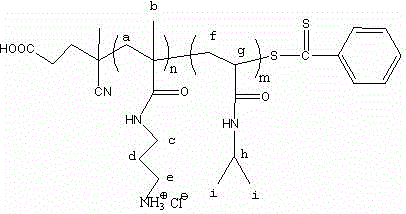

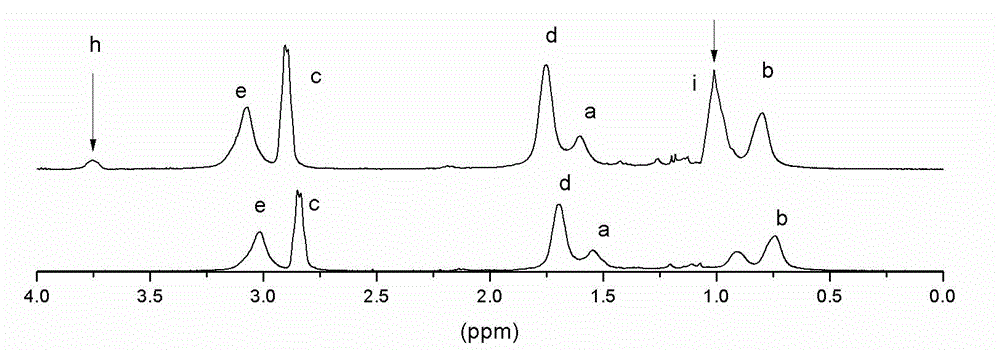

[0026] The first step of synthesis: Dissolve 3.6g of N-3-aminopropylmethacrylamide hydrochloride monomer in 8ml of deionized water, adjust the pH to 4~5 and freeze it, and dissolve 0.06g of 4-cyano-4 -(Thiobenzoyl)valeric acid and 0.015g 4,4'-azo-(4-cyanovaleric acid) were dissolved in 0.5ml of dioxane solvent, and the two were mixed in a one-necked bottle. The rotor is contained inside, and the glass tee is connected to it, the air is completely excluded, and the solution is placed in a nitrogen-protected environment, and the oil bath is heated to 70°C for 16 hours. Dialyzed in medium for three days, and then freeze-dried to obtain poly(N-3-aminopropylmethacrylamide hydrochloride) polymer.

[0027] The second step of synthesis: Take 0.27g of poly(N-3-aminopropylmethacrylamide hydrochloride) as a macromolecular chain transfer agent and place it in a single-necked bottle containing a rotor, and add 1.5mg of 4,4'- Nitrogen-(4-cyanovaleric acid), 0.7g N-isopropylacrylamide monom...

Embodiment 2

[0032] Same as Example 1, but the amount of 4,4'-azo-(4-cyanovaleric acid) in the first step of synthesis becomes 0.012g of the monomer in the system (N-3-aminopropylmethacrylamide hydrochloride salt) to chain transfer agent (4-cyano-4-(thiobenzoyl)valeric acid) and initiator (4,4'-azo-(4-cyanovaleric acid)) molar ratio is 100:1:0.2.

Embodiment 3

[0034] Same as Example 1, but the water solvent in the first step of synthesis is changed to 15ml, the monomer (N-3-aminopropylmethacrylamide hydrochloride) and the chain transfer agent (4-cyano-4-( Thiobenzoyl)valeric acid) and initiator (4,4'-azo-(4-cyanovaleric acid)) molar ratio is still 100:1:0.25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com