Heterojunction solar cell structure and manufacturing method thereof

A technology for solar cells and fabrication methods, which are applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the series resistance of heterojunction cells, low photoelectric conversion efficiency, and high TCO resistivity, so as to improve battery efficiency and reduce battery Resistivity, the effect of improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

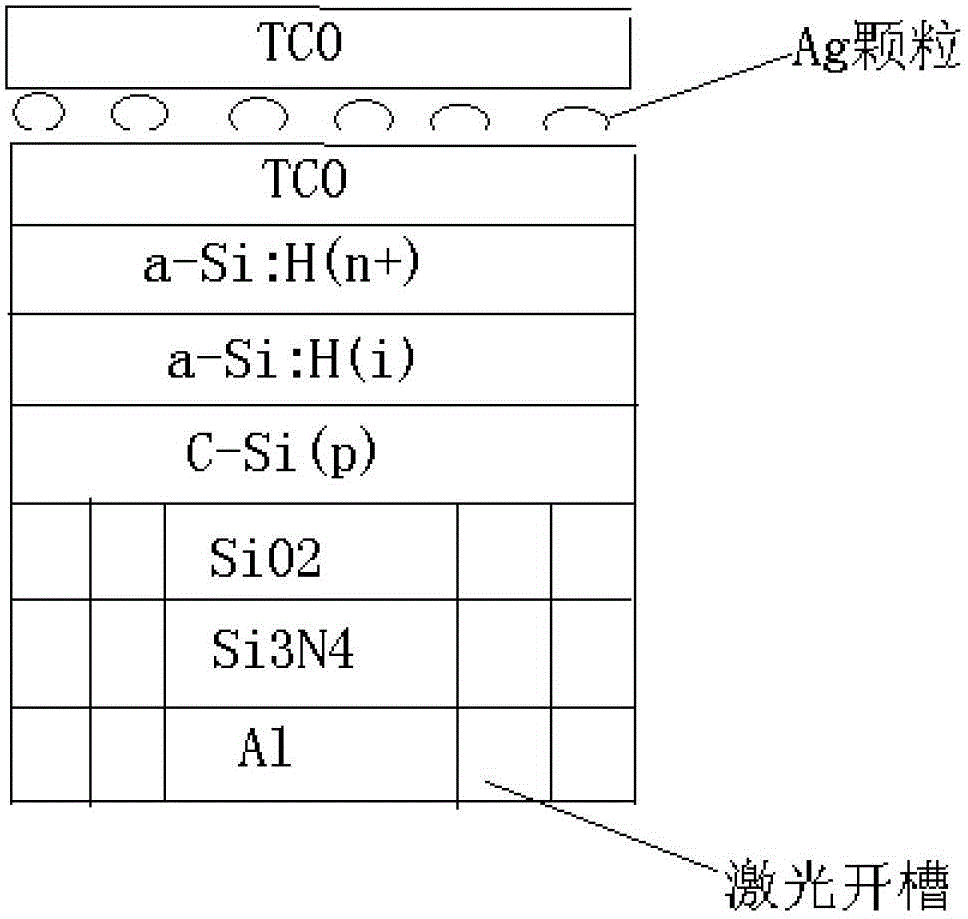

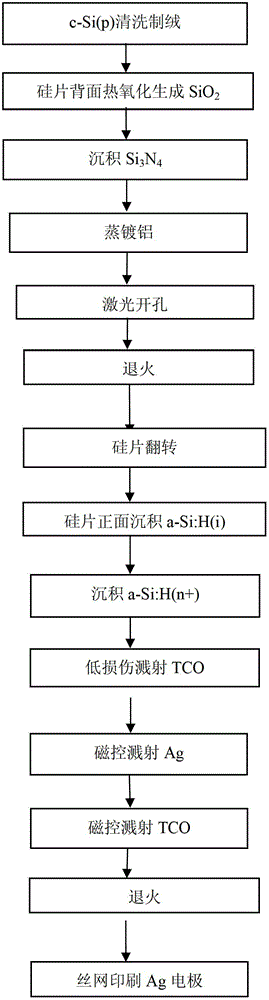

[0016] A heterojunction solar cell structure, comprising a silicon wafer substrate, an amorphous silicon layer for forming a heterojunction on the light-receiving surface of the silicon wafer substrate, a transparent conductive film on the amorphous silicon layer, and a transparent conductive film on the transparent conductive film Make the gate line, the transparent conductive film includes the bottom TCO layer, the middle Ag layer and the surface TCO layer, the bottom TCO layer is 10-20nm thick, the middle Ag layer is 10-15nm, and the surface TCO layer is 80-100nm thick .

[0017] Such as figure 1 As shown, the silicon wafer substrate is P-type, and the amorphous silicon layer on the P-type silicon wafer substrate includes an intrinsic amorphous silicon layer and an n+ amorphous silicon layer on the intrinsic amorphous silicon layer.

[0018] A silicon dioxide layer, a silicon nitride layer and an aluminum layer are sequentially arranged on the backlight surface of the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com