Ceramic honeycombed catalyst capable of purifying organic waste gas and preparation method thereof

A ceramic honeycomb, organic waste gas technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. problems, to achieve the effect of prolonging contact time, improving stability and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Ceramic honeycomb catalyst A1 for purifying organic waste gas

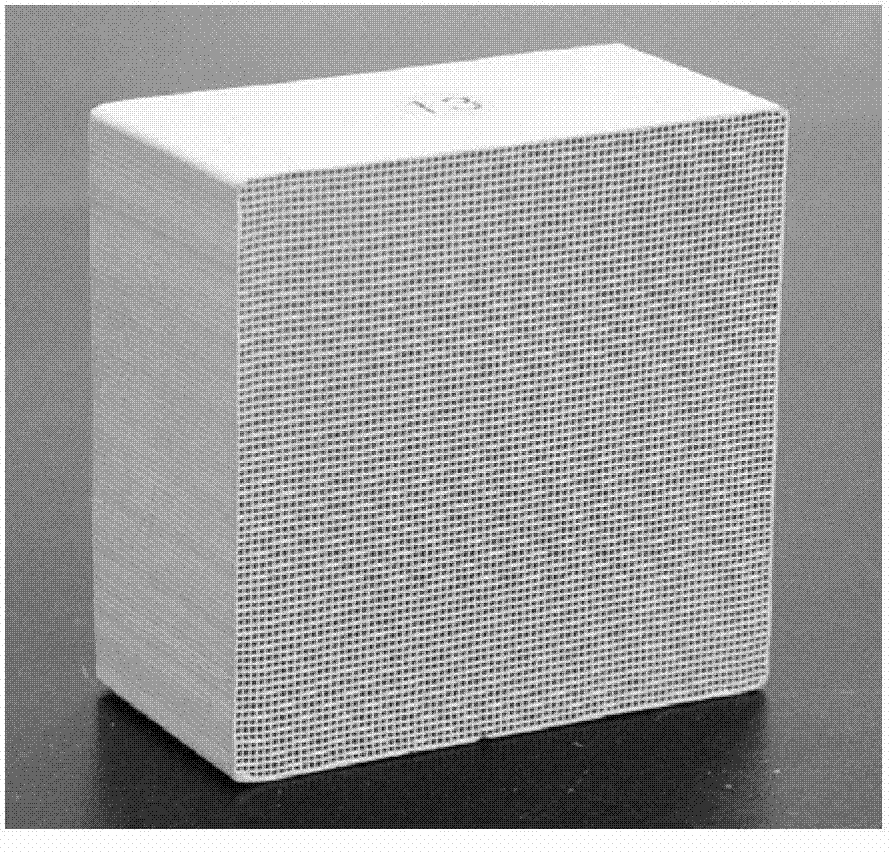

[0021] The ceramic honeycomb carrier is a 50-mesh cube with a shape of 100mm*100mm*100mm;

[0022] (1) Preparation of coating slurry: Weigh 3500 grams of deionized water, add 1200 grams of alumina, 600 grams of cerium-zirconium composite oxide (the molar ratio of cerium to zirconium is 3:1), 400 grams of cerium nitrate, and stir. Evenly, until the nitrate is completely dissolved, use a ball mill to ball mill the slurry with a particle size D90 of less than 20 microns, and dropwise add palladium nitrate containing 15% of palladium during stirring to obtain a slurry for coating;

[0023] (2) Coating and drying: After weighing the 300-mesh cordierite honeycomb ceramic carrier with a long axis of 100 mm, a wide axis of 100 mm, a height of 100 mm, and a volume of 1 L, soak it in the coating slurry obtained in step (1) and stay for 1 to 3 s. , take out at a speed of 10~150mm / s; bake the cordierite hone...

Embodiment 2

[0029] Example 2 Ceramic honeycomb catalyst A2 for purifying organic waste gas

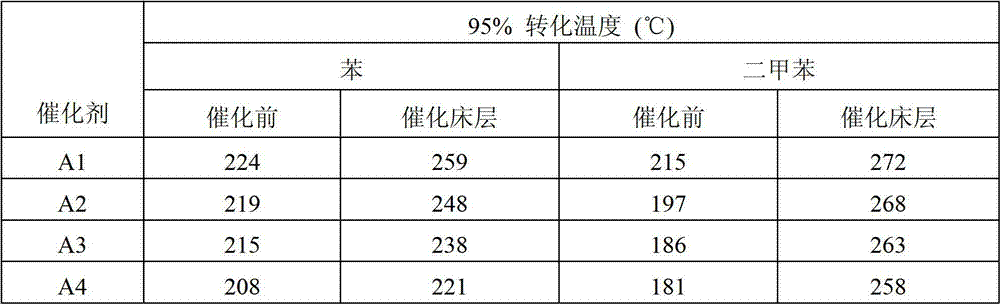

[0030] The specific preparation method is basically the same as Example 1 of this part, except that the mesh number of the carrier is 100 meshes. The results of catalyst activity evaluation and bed temperature test are shown in Table 1.

Embodiment 3

[0031] Example 3 Ceramic honeycomb catalyst A3 for purifying organic waste gas

[0032] The specific preparation method is basically the same as that of Example 1 of this part, the difference is that the mesh number of the carrier is 200 meshes. The results of catalyst activity evaluation and bed temperature test are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com