Infrared absorption heat preservation film

A technology of infrared absorption and thermal insulation film, applied in the direction of plant protection cover, synthetic resin layered products, layered products, etc., can solve the problems of unfavorable crop growth, temperature drop, etc., achieve good absorption and reflection ability, reduce the ratio, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the infrared absorption thermal insulation film is as follows: various resins such as EVA, PE and related functional masterbatches such as anti-infrared masterbatches, dripping anti-fogging agents, anti-aging agents and other related masterbatches are put into the warehouse and automatically batched. Among them, the infrared absorbing heat preservation agent is added in the form of an anti-infrared masterbatch using LDPE or LLDPE as a carrier, and the mass ratio of the infrared absorbing heat preservation agent in LDPE or LLDPE is 40-60%; it is weighed and sent into a three-layer co-extrusion The screw of the film blowing equipment is mixed and extruded to be plasticized into a melt; the filter is filtered, and then diverted to the die head through the flow channel, and extruded to form a composite film; the extruded film is then blown, drawn, folded, and rolled to form Finished insulation film.

[0025] The preparation of the thermal insulatio...

Embodiment 1

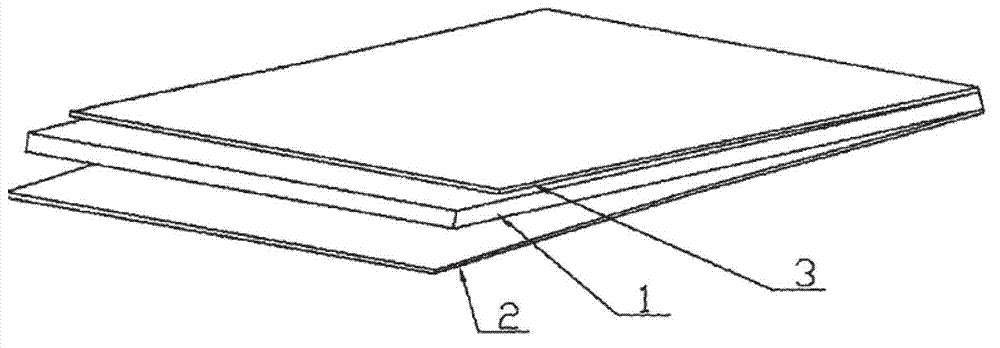

[0028] An infrared absorbing thermal insulation film with a three-layer co-extruded composite film structure comprising an inner layer, a middle layer and an outer layer. Among them, the outer layer material is PE with 12% anti-aging agent and 3% slow-release agent, and the middle layer material is added with 8% infrared absorbing heat preservation agent, 12% anti-aging agent, 10% dripping anti-fogging agent, 3% The PE and EVA of the slow release agent, the inner layer is made of PE with 12% anti-aging agent, 10% dripping anti-fogging agent, and 3% slow release agent. In the middle layer, EVA and PE are used in a weight ratio of 1:2.

[0029] Among them, the infrared absorbing thermal insulation agent is a masterbatch formed by plasticizing one or more of calcium carbonate, diatomite, and talcum powder with LDPE as the carrier. The weight ratio of calcium carbonate, diatomite, and talcum powder is 75:20:5; and the mass ratio of the infrared absorbing thermal insulation agent ...

Embodiment 2

[0033] An infrared absorbing thermal insulation film with a three-layer co-extruded composite film structure comprising an inner layer, a middle layer and an outer layer. Among them, the outer layer material is PE with 10% anti-aging agent, 2% slow-release agent, and 1% opening agent, and the middle layer material is added with 4% infrared absorbing heat preservation agent, 10% anti-aging agent, and 10% dripping anti-aging agent. Fog agent, EVA with 5% heat preservation agent, the inner layer is made of EVA and PE with 10% anti-aging agent, 10% dripping anti-fogging agent, 2% slow-release agent, and 1% opening agent. In the inner layer, the weight ratio of EVA and PE is 1:2.2.

[0034] Among them, the infrared absorbing heat preservation agent is a masterbatch formed by mixing and plasticizing one or more of calcium carbonate, hydrotalcite, and diatomite with LLDPE as the carrier. The weight ratio of calcium carbonate, hydrotalcite, and diatomite added is It is 70:20:10; and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com