Preparation method of conductive polyethylene glycol terephthalate composite material

A technology of ethylene glycol phthalate and composite materials, which is applied in the field of preparation of composite materials, can solve the problems that the in-situ polymerization of polyaniline cannot be guaranteed, the preparation methods are complicated, and the results are unsatisfactory. Effect of enhancing binding force and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

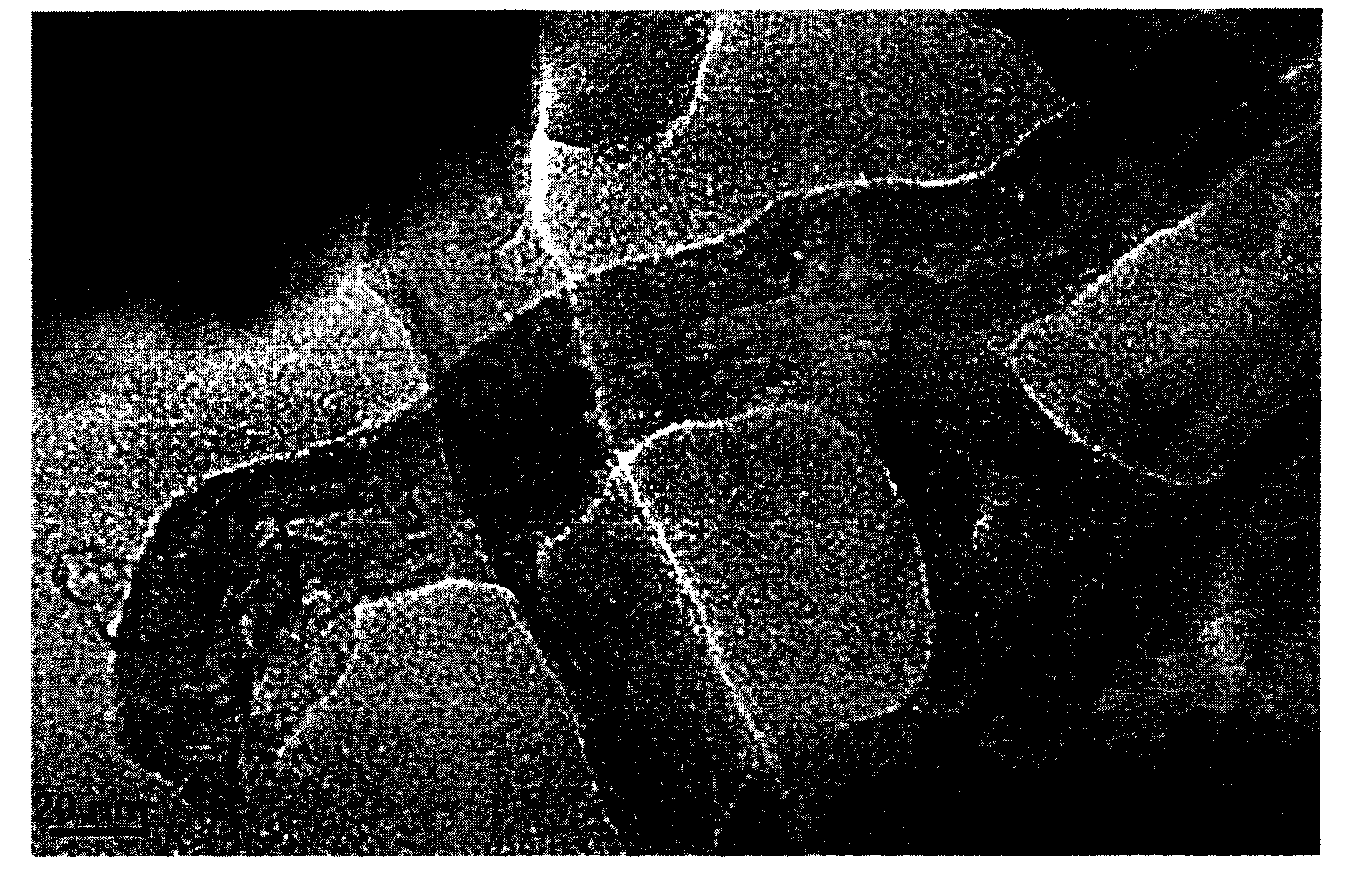

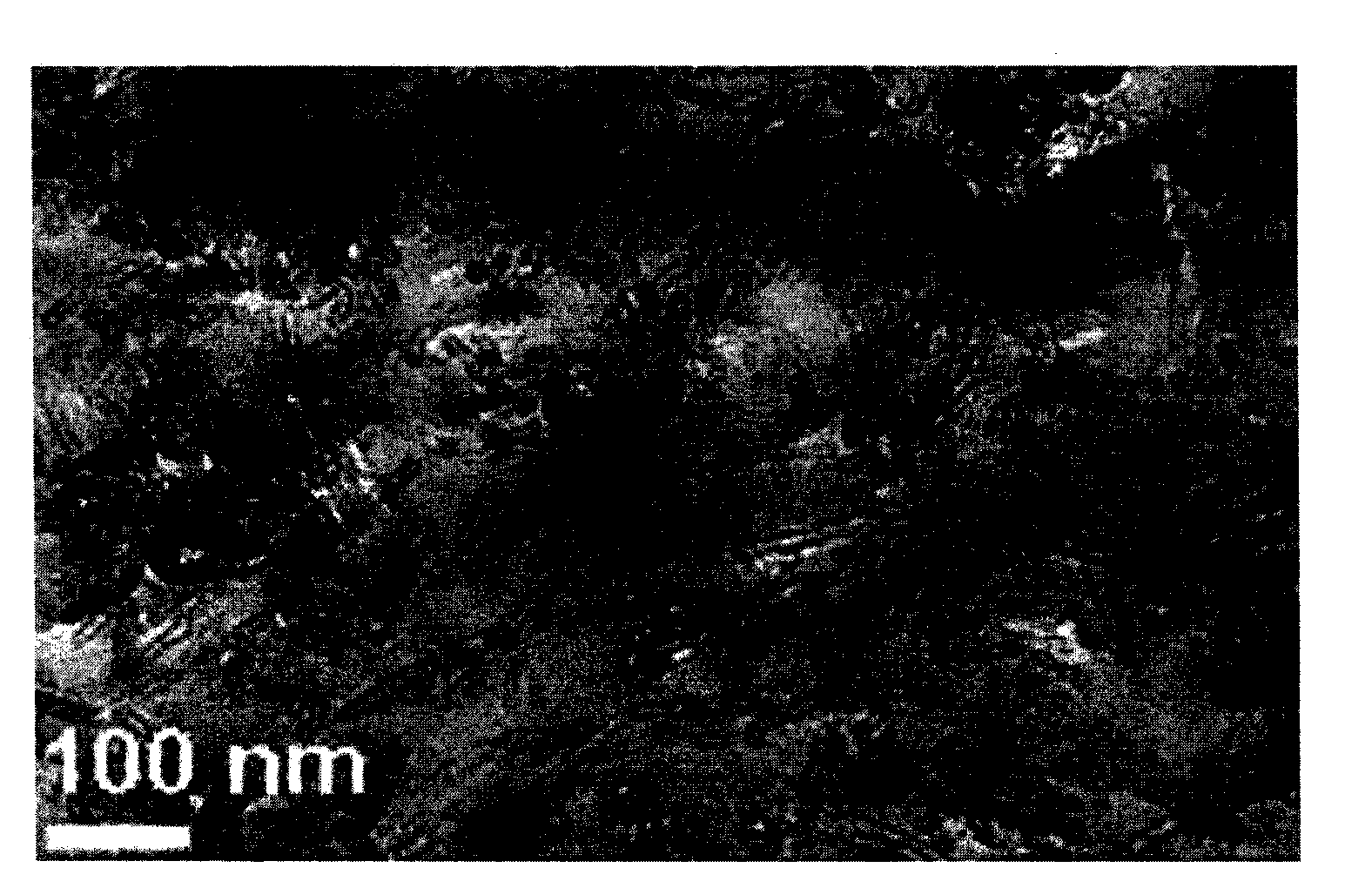

Image

Examples

Embodiment 1

[0020] Step 1, first mix carbon nanotubes and aniline according to the mass ratio of 0.8: 1.2 and then mix and stir and ultrasonically homogenize for 15min and 14min, then add a co-stabilizer; wherein the co-stabilizer is hexadecane, which is mixed with The mass ratio between anilines is 0.8:30 to obtain a mixture. Then add the mixture to an emulsifier aqueous solution with a concentration of 0.0075mol / L, stir and ultrasonically homogenize for 15min and 14min in turn; wherein, the emulsifier is cetyl sodium sulfate, and the mass ratio between it and the aniline in the mixture is 0.8 : 30, a fine emulsion was obtained.

[0021] Step 2, first add protonic acid aqueous solution to the miniemulsion and then stir for 10 minutes; wherein, the protonic acid is hydrochloric acid with a concentration of 1.5mol / L, and the molar ratio between it and the aniline in the miniemulsion is 0.8:1.2, and the doped liquid. Then, dropwise add an aqueous solution of an oxidizing agent with a conc...

Embodiment 2

[0024] Step 1, first mix carbon nanotubes and aniline according to the ratio of 0.9:1.1 in mass ratio, mix and stir and ultrasonically homogenize for 16min and 13min, then add a co-stabilizer; wherein, the co-stabilizer is hexadecane, which is mixed with The mass ratio between the anilines was 0.9:28, resulting in a mixture. Then add the mixture to an emulsifier aqueous solution with a concentration of 0.0076mol / L and stir and ultrasonically homogenize for 16min and 13min successively; wherein, the emulsifier is cetyl sodium sulfate, and the mass ratio between it and the aniline in the mixture is 0.9 : 28, a fine emulsion was obtained.

[0025] Step 2, first add protonic acid aqueous solution to the miniemulsion and then stir for 11 minutes; wherein, the protonic acid is hydrochloric acid with a concentration of 0.8mol / L, and the molar ratio between it and the aniline in the miniemulsion is 0.9: 1.1, and the doped liquid. Then, dropwise add an aqueous solution of an oxidizin...

Embodiment 3

[0028] Step 1, first mix carbon nanotubes and aniline according to the ratio of mass ratio of 1:1, mix and stir and ultrasonically homogenize for 17min and 12min, then add a co-stabilizer; wherein, the co-stabilizer is hexadecane, which is mixed with The mass ratio between anilines is 1:25 to obtain a mixture. Then add the mixture to the emulsifier aqueous solution with a concentration of 0.0077mol / L and stir and ultrasonically homogenize for 17min and 12min successively; wherein, the emulsifier is cetyl sodium sulfate, and the mass ratio between it and the aniline in the mixture is 1 : 25, a fine emulsion was obtained.

[0029] Step 2, first add protonic acid aqueous solution to the miniemulsion and then stir for 12 minutes; wherein, the protonic acid is hydrochloric acid with a concentration of 1mol / L, and the molar ratio between it and aniline in the miniemulsion is 1:1 to obtain the doping solution . Then, dropwise add an aqueous solution of an oxidizing agent with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com