Anti-infection mineralized collagen and calcium sulfate bone repair material and preparation method thereof

A technology for mineralized collagen and bone repair, applied in medical science, prosthesis, etc., can solve the problems of poor biocompatibility, short concentration time, non-degradation, etc., achieve good biocompatibility, good injectability, promote The effect of adhesive spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Hydrothermal method to prepare α-type calcium sulfate hemihydrate: CaSO 4 ·2H 2 O, added to the reaction kettle, respectively take CaSO 4 ·2H 2 O 0.25% sodium citrate and aluminum sulfate are added to the reactor, and then CaSO 4 ·2H 2 Deionized water of 5.67 times the mass of O, airtight the reactor, stir at 120°C, and react for 6 hours; after the reaction is completed, the reaction solution is hot and filtered, and then the filter cake is washed with deionized boiling water. The filtrate during the whole process And the temperature of the rinsing liquid is above 90℃; put the drained filter cake in a drying box at 100℃ and dry overnight to obtain α-type calcium sulfate hemihydrate; grind with a mortar, sieving with a 100 mesh stopper, and obtain a uniform particle size Alpha-type calcium sulfate hemihydrate powder.

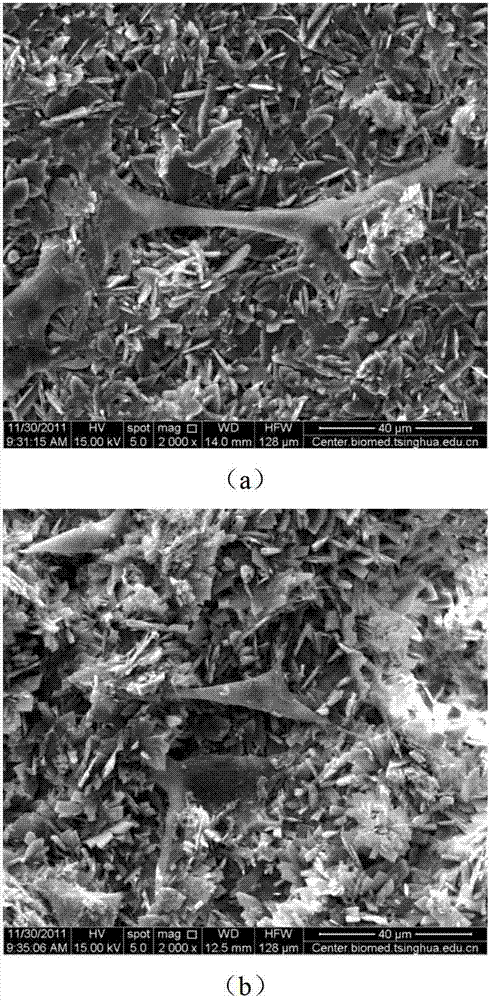

[0019] Preparation of mineralized collagen: Dissolve collagen with a solid content of 1% in glacial acetic acid, the concentration of the collagen solution is...

Embodiment 2

[0022] The preparation of mineralized collagen and α-type calcium sulfate hemihydrate was the same as in Example 1.

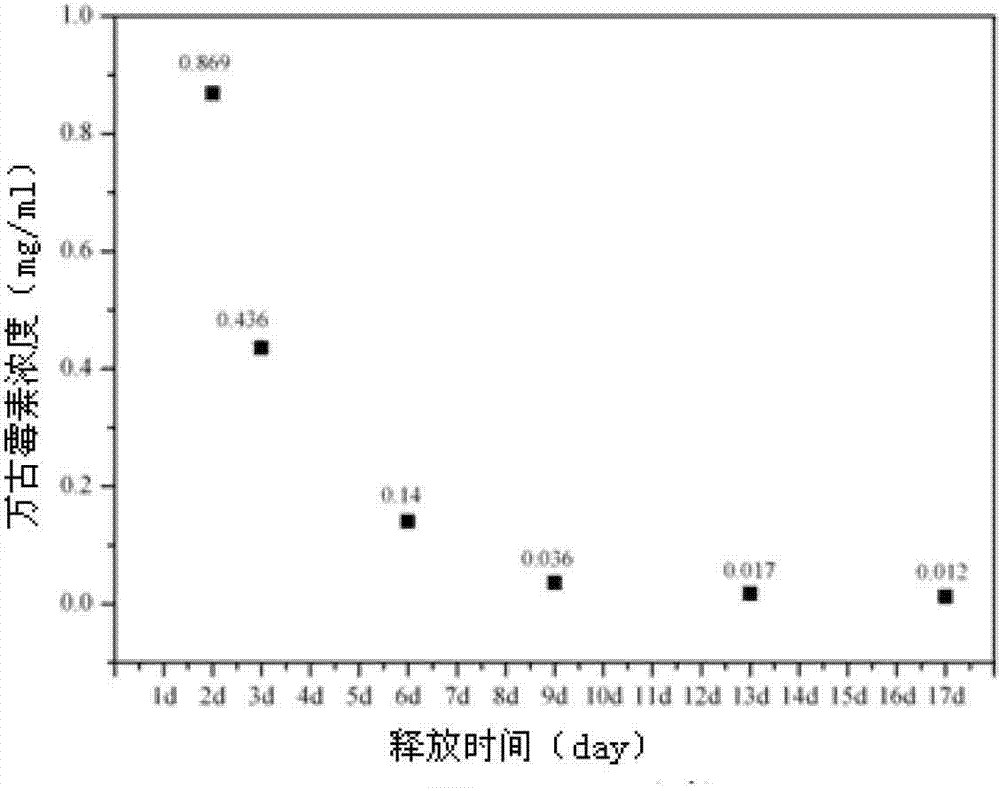

[0023] Add mineralized collagen, vancomycin, and calcium sulfate dihydrate in the proportions of 2 wt %, 10 wt %, and 20 wt% respectively into the remaining α-type calcium sulfate hemihydrate and mix well to obtain anti-infective mineralized collagen-sulfuric acid Calcium bone repair material.

Embodiment 3

[0025] The preparation of mineralized collagen and α-type calcium sulfate hemihydrate was the same as in Example 1.

[0026] Add mineralized collagen, vancomycin, and calcium sulfate dihydrate in the proportions of 2 wt %, 15 wt %, and 20 wt% respectively into the remaining α-type calcium sulfate hemihydrate and mix well to obtain anti-infective mineralized collagen-sulfuric acid Calcium bone repair material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com