Method for preparing porous membranes based on selective swelling of block copolymers

A block copolymer and selective technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as by-products, lack of universal applicability, complicated operation process, etc., to achieve high Intensity, ease of handling, results with less use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a) Weigh 0.02 g of polystyrene and poly(2-vinylpyridine) block copolymer (poly(2-vinylpyridine) volume ratio is 25%), dissolve it in 0.98 g of chloroform, and prepare Polymer mass fraction is the solution of 2%;

[0030] b) Take a piece of polyvinylidene fluoride (PVDF) membrane (the membrane area is about 6.25 square centimeters), soak it in water for 1 minute, take it out, and spread it on a smooth glass substrate;

[0031] c) Wipe off the water on the surface of the PVDF membrane, and then take 0.1 ml of the prepared block copolymer solution and apply it evenly on the entire surface of the PVDF membrane;

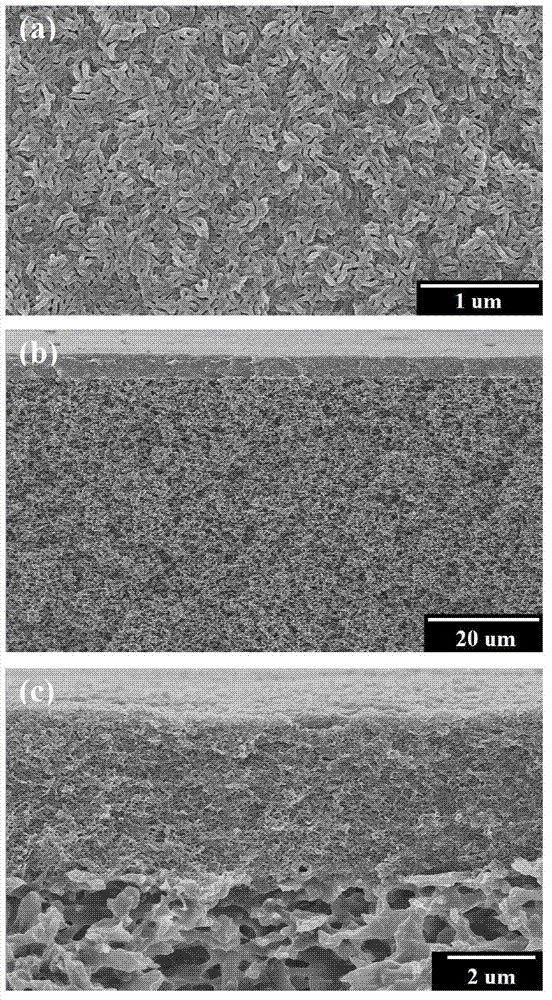

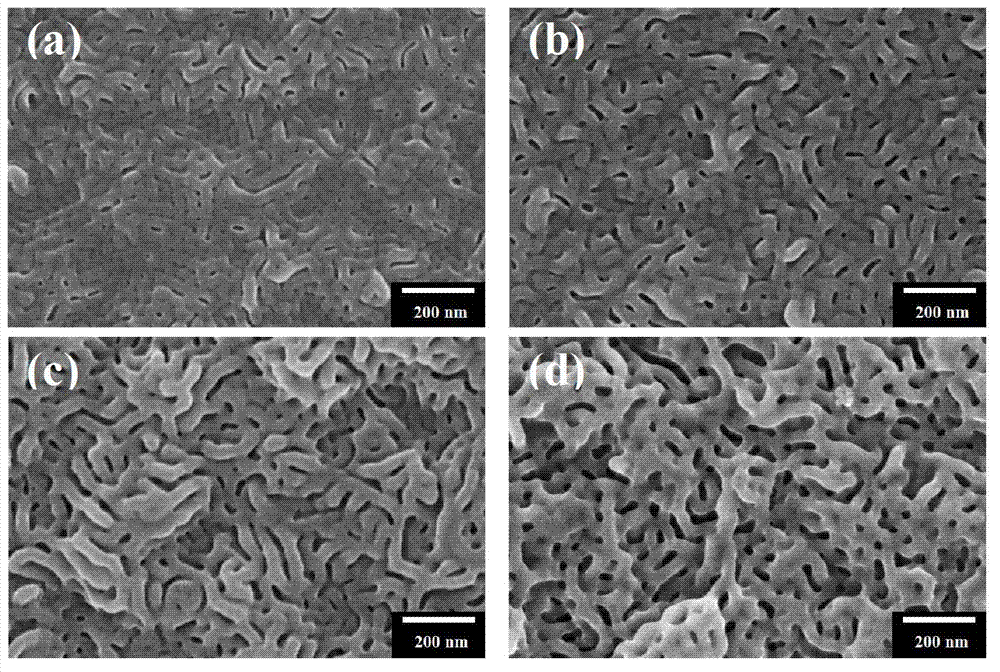

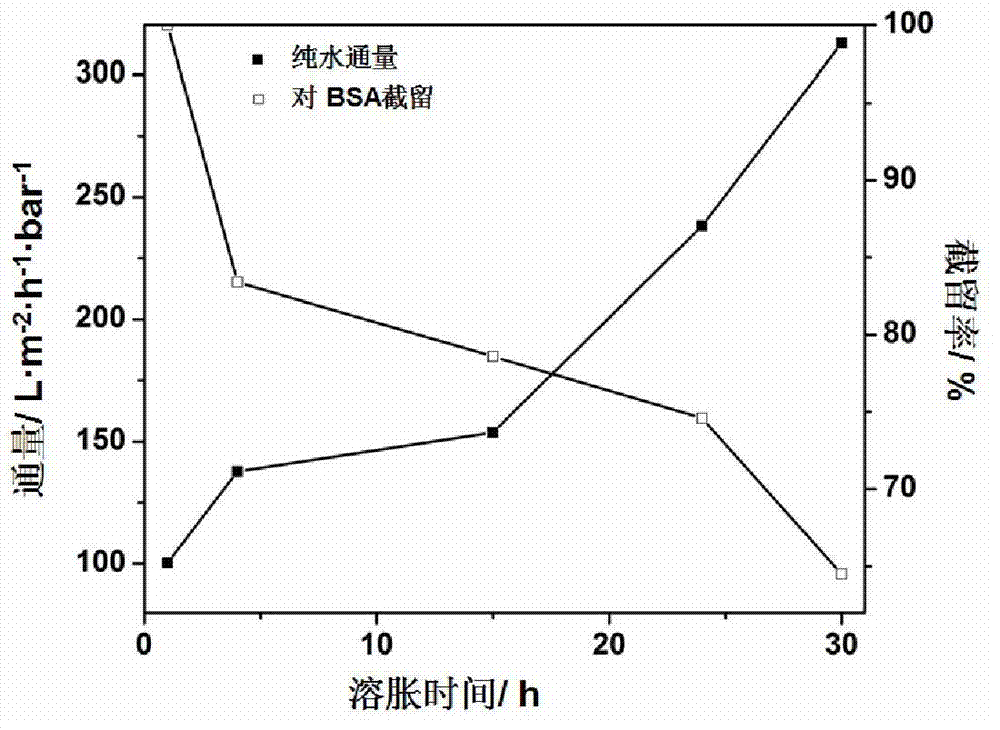

[0032] d) Place the glass sheet loaded with PVDF film (coated with block copolymer solution) in a vacuum drying oven at 130°C for 20 minutes, then deflate, open the door of the drying oven and turn off the power of the drying oven , so that the natural cooling of the box for 3 hours. Through this step, the block copolymer solution is dried to form a film on the P...

Embodiment 2

[0040] a) Weigh 0.5 g of block copolymer of polymethylstyrene and polydimethylaminoethyl methacrylate (the volume ratio of polydimethylaminoethyl methacrylate is 10%), dissolve it in 0.5 g of toluene, Be prepared as the solution that polymer mass fraction is 50%;

[0041] b) Take a piece of polyethersulfone (PES) membrane (the membrane area is about 6.25 square centimeters), soak it in glycerol for 5 minutes, take it out, and spread it on a smooth glass substrate;

[0042] c) Wipe off the glycerol on the surface of the PES membrane, and then take 0.05 ml of the prepared block copolymer solution and apply it evenly on the entire surface of the PES membrane;

[0043] d) Put the glass sheet loaded with PES film (coated with block copolymer solution) in a vacuum drying oven at 100°C, vacuumize for 30 minutes, then release the air, open the door of the drying oven and turn off the power of the drying oven , so that the natural cooling of the box for 2 hours. After this step, the ...

Embodiment 3

[0048] a) Weigh 0.01 g of polymethyl acrylate and poly(4-vinylpyridine) block copolymer (poly(4-vinylpyridine) volume ratio is 50%), and dissolve it in 0.99 g of dimethyl sulfoxide , to be prepared as a solution with a polymer mass fraction of 1%;

[0049] b) Take a piece of nylon membrane (the membrane area is about 6.25 square centimeters), soak it in silicone oil for 5 minutes, take it out, and spread it on a smooth glass substrate;

[0050] c) Wipe off the silicone oil on the surface of the nylon membrane, and then take 0.2 ml of the prepared block copolymer solution and apply it evenly on the entire surface of the nylon membrane;

[0051] d) Put the glass sheet loaded with nylon membrane (coated with block copolymer solution) in a vacuum drying oven at 160°C, vacuumize for 20 minutes, then release the air, open the door of the drying oven and turn off the power of the drying oven , so that the natural cooling of the box for 10 hours. After this step, the block copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com