A kind of composite nano coating and preparation method thereof

A nano-coating, nano-technology, applied in the field of coatings, can solve problems affecting human health, pollution, etc., and achieve the effect of strong adhesion and strong thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

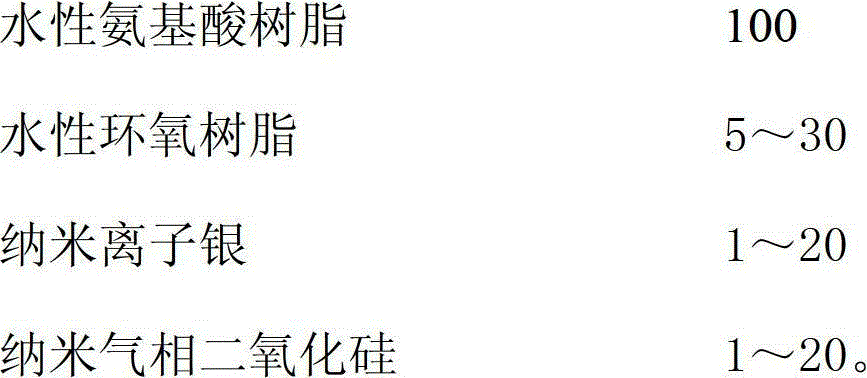

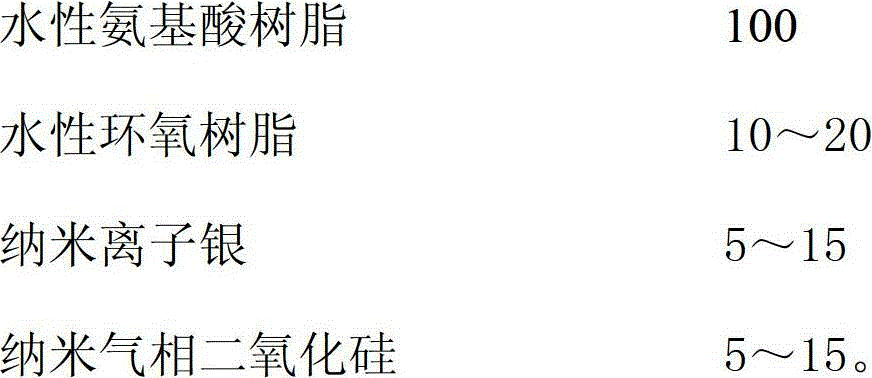

Method used

Image

Examples

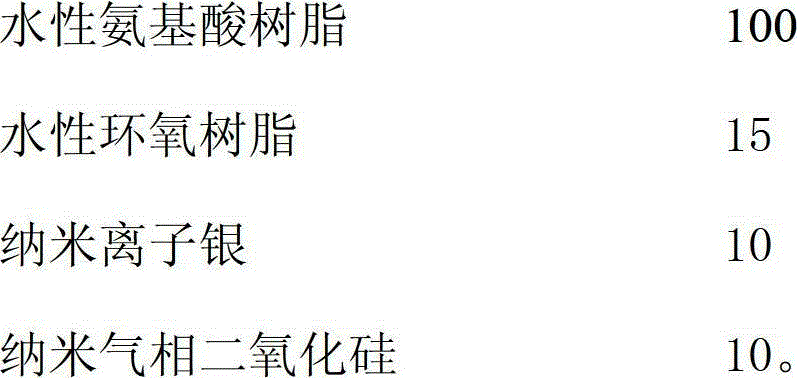

Embodiment 1

[0021] Weigh 100g of water-based polyurethane and 15g of water-based epoxy resin, and mix them, then disperse them with a high-speed disperser for 5 minutes, then add 10g of nano-ionic silver, 10g of release agent, 2g of leveling agent, 2g of dispersant, 2g of adhesive and 2g defoamer, disperse for another 10min, defoam, then add 10g nano fumed silica, after dispersion, add 120g water and 50g alcohol, fully disperse for 30min, then carry out nanoscale sand milling.

Embodiment 2

[0023] Weigh 100g of water-based polyurethane and 5g of water-based epoxy resin, mix them, and disperse them with a high-speed disperser for 10 minutes, then add 1g of nano-ionic silver, 1g of release agent, 0.2g of leveling agent, 0.2g of dispersant, and 0.2g of Adhesive agent and 0.2g defoaming agent, then dispersed for 15 minutes, defoamed, then added 1g of nano fumed silica, after dispersion, added 30g of water and 5g of alcohol, fully dispersed for 30 minutes and then carried out nano-scale sand milling.

Embodiment 3

[0025] Weigh 100g of water-based polyurethane and 10g of water-based epoxy resin, mix them, and disperse them with a high-speed disperser for 15 minutes, then add 5g of nano-ionic silver, 5g of release agent, 5g of leveling agent, 1g of dispersant, 1g of adhesive and 1g defoamer, disperse for another 30 minutes, defoam, then add 5g of nano fumed silica, after dispersion, add 60g of water and 30g of alcohol, fully disperse for 40min, then carry out nano-scale sand milling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com