Preparation method of mesoporous carbon material

A mesoporous carbon and nanoparticle technology is applied in the field of preparation of mesoporous carbon materials, which can solve the problems of inconvenient production and operation, environmental pollution, etc., and achieve the effects of reducing production costs, reducing costs, and simple and reliable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

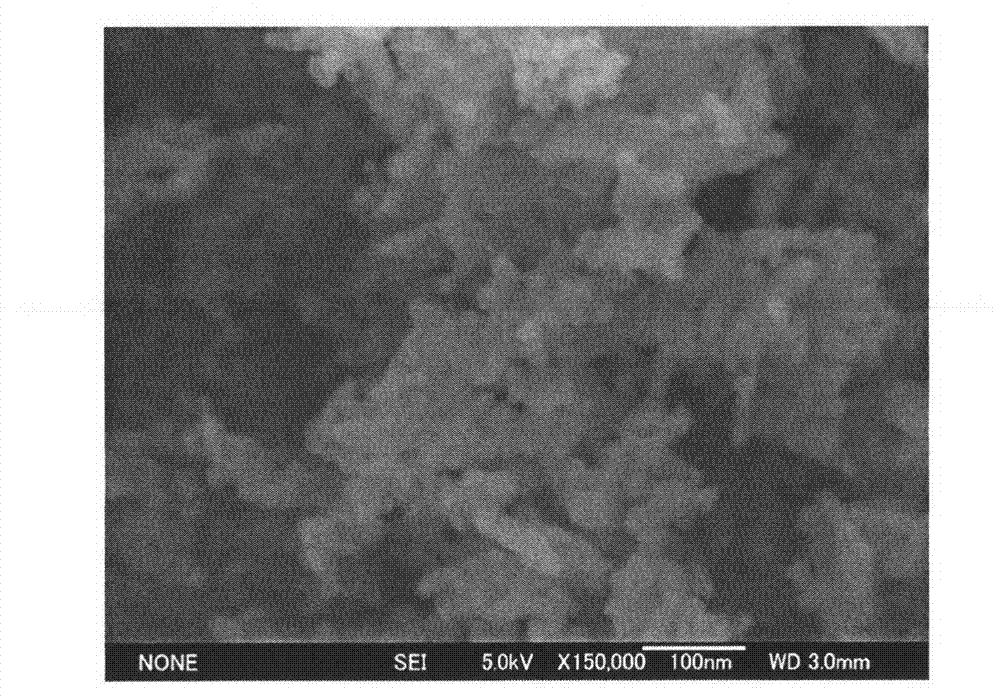

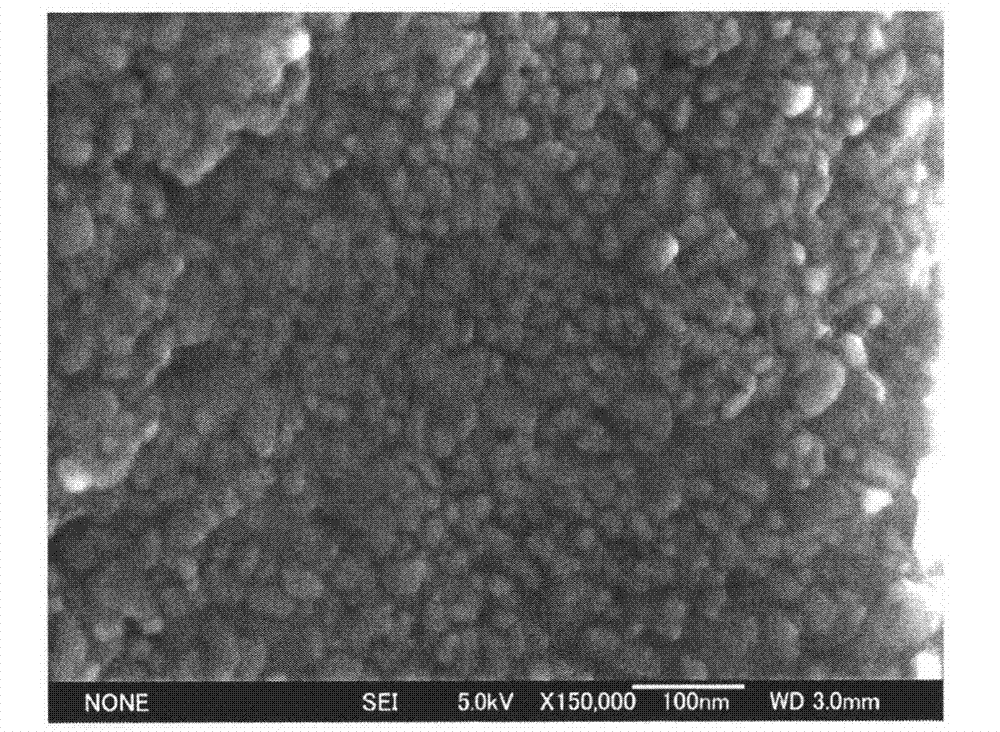

[0020] Put 3g ZnO nanoparticles on 25cm 3 10 g of 10% polyacrylamide was added to the distilled water after a little stirring. After the mixed solution was stirred at 700 rpm for 4 hours, it was dispersed by ultrasonic waves for 1 hour. The ZnO / polyacrylamide nanocomposite can be obtained after drying at 100°C for 4 hours. figure 1 with 2 Electron micrographs of ZnO raw materials and ZnO / polyacrylamide nanocomposites are listed respectively. The ZnO raw material is some agglomerated nanoparticles, and the ZnO / polyacrylamide nanocomposite shows that the ZnO nanoparticles are well dispersed in the polyacrylamide polymer one by one.

[0021] The obtained ZnO / polyacrylamide nanocomposite was treated in 97%N 2 +3%H 2 The C / ZnO nanocomposite was obtained by firing at 700°C for 3 hours in an atmosphere.

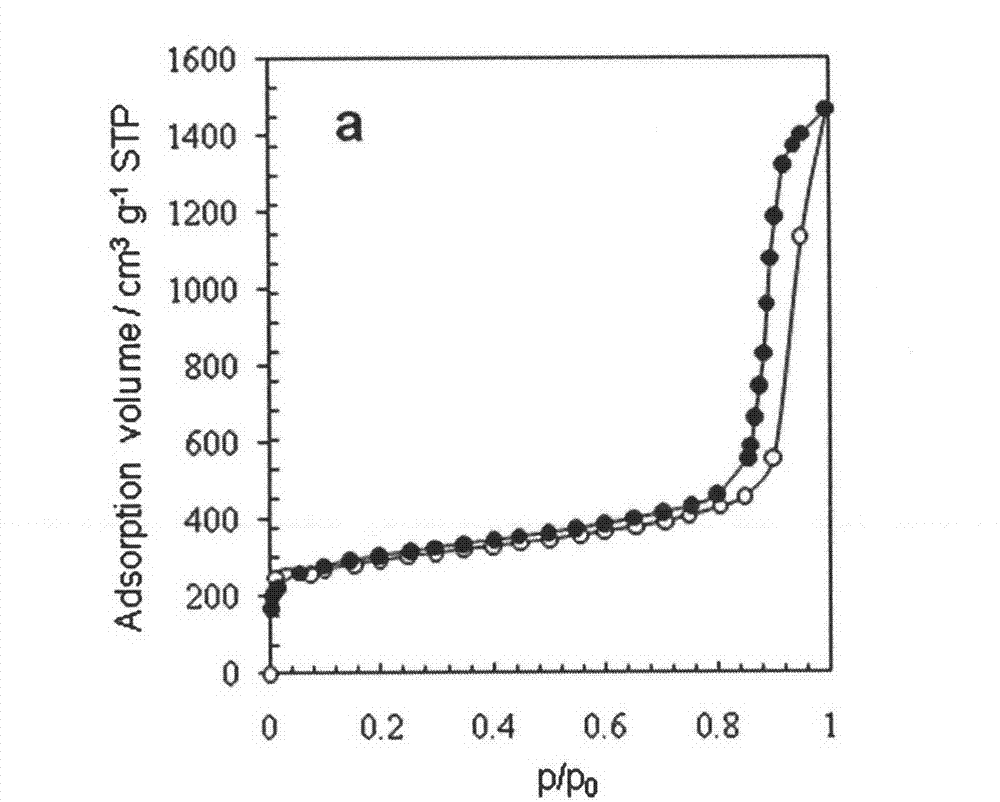

[0022] In 10% acetic acid solution 50cm 3 After the C / ZnO nanocomposite was treated to dissolve the ZnO template, the mesoporous carbon material was obtained after washing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com