Preparation method for bulleyaconitine A

A technology for clathrin and methanol, applied in the field of preparation of high-purity clathrate, can solve the problems of high cost, complicated method steps, difficult recovery and reuse, etc., achieves a high degree of fluidization, reduces production costs, The effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

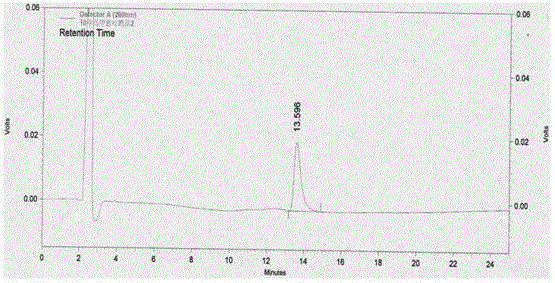

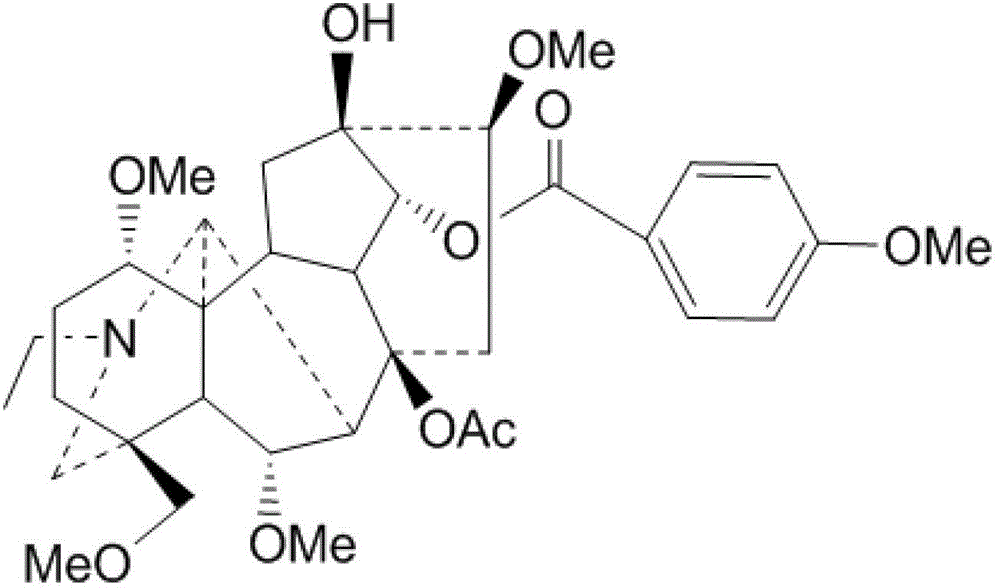

Image

Examples

Embodiment 1

[0014] The preparation method of aconitin provided by the invention specifically comprises the following processing steps:

[0015] (1) extract

[0016] Crush the dried roots of Aconitum transsectum Diels., infiltrate them with an appropriate amount of methanol for 24 hours, and use methanol for percolation extraction. The amount of methanol used is 8 to 15 times the amount of medicinal materials. Combine the leachate and concentrate to a paste.

[0017] (2) Extraction and separation

[0018] Dissolve the paste obtained in step (1) with 1.5% hydrochloric acid solution, filter, adjust the pH to 9 with concentrated ammonia water (25%), and extract the lye twice with petroleum ether, then use chloroform or ethyl acetate Extract 3 times, combine chloroform or ethyl acetate and recover chloroform under reduced pressure to a paste to obtain crude total alkali.

[0019] (3) Separation and purification by column chromatography

[0020] The crude total alkali obtained in step (2) wa...

Embodiment 2

[0026] Take 10 kg of dried roots of Aconitum aconitum, crush them, infiltrate them with an appropriate amount of methanol for 24 hours, and use methanol for percolation extraction. The amount of methanol used is 10 times the amount of medicinal materials. Dissolve, filter, adjust pH to 9 with concentrated ammonia water (25%), and extract lye with petroleum ether twice, 5 liters each; Compress and recover to a paste to obtain 110 g of crude total alkali. The crude total alkali was dissolved in 300 ml of chloroform and adsorbed on 164 g of 200-300 mesh silica gel to mix the sample, evaporated to dryness at room temperature, and subjected to silica gel column chromatography, with a gradient of petroleum ether: diethylamine (50:1-20:2) Elution, collect the eluate, use Aconitin as a control with thin-layer chromatography [developing solvent is petroleum ether: acetone: diethylamine (20:1:1)] tracking detection, and combine the main components containing Aconitin Fractions, the sol...

Embodiment 3

[0028] Take 10 kg of dried roots of Aconitum aconitum, crush them, infiltrate them with an appropriate amount of methanol for 24 hours, and use methanol for diafiltration extraction. The amount of methanol used is 8 times the amount of medicinal materials. Combine the leachate, concentrate to paste, and use 1.5% hydrochloric acid solution Dissolve, filter, adjust pH to 9 with concentrated ammonia water (25%), and extract lye with petroleum ether twice, 5 liters each; then extract 3 times with chloroform, 5 liters each time, combine chloroform solution, Recover under reduced pressure to a creamy state to obtain 105 g of crude total alkali. The crude total alkali was dissolved in 300 ml of chloroform and adsorbed on 160 g of 200-300 mesh silica gel to mix the sample, evaporated to dryness at room temperature, and subjected to silica gel column chromatography, with a gradient of petroleum ether: diethylamine (50:1-20:2) Elution, collect the eluate, use Aconitin as a control with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com