Natural chlorophyll iron magnesium salt and method for preparing same

A technology of chlorophyll and iron-magnesium, which is applied in the field of preparation of natural chlorophyll iron-magnesium salt, and achieves the effects of simple and convenient preparation method, high yield and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

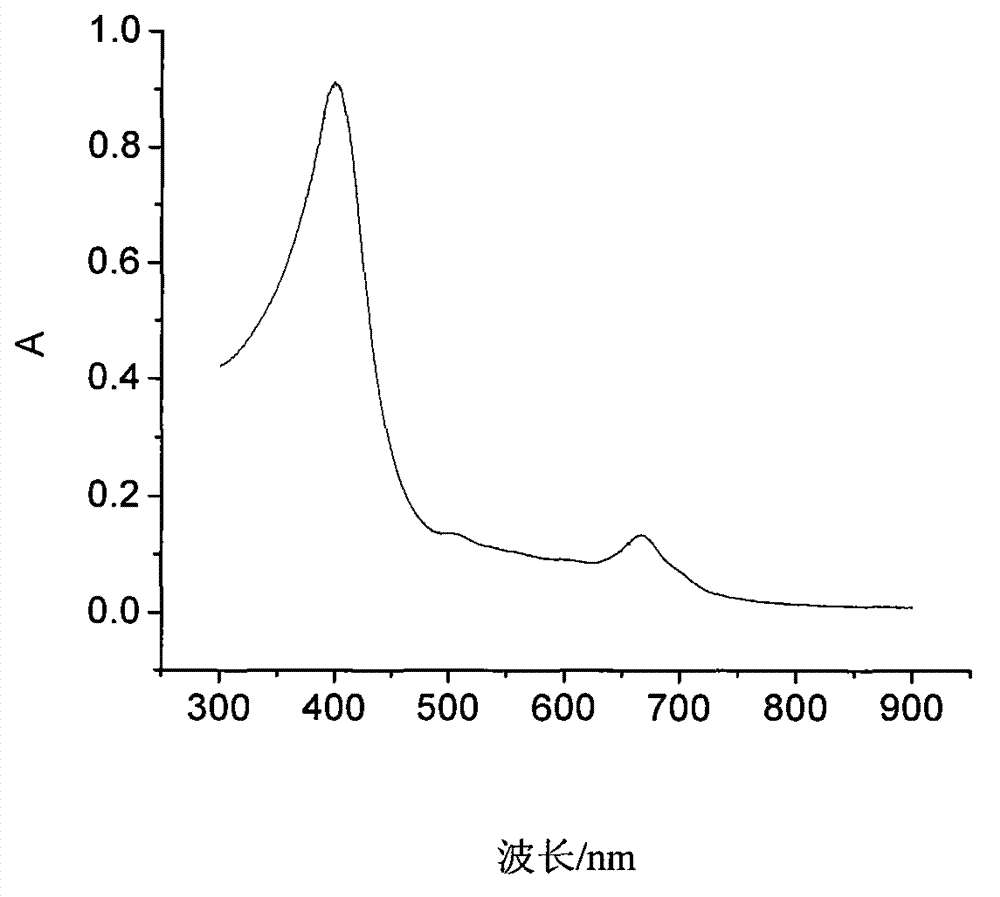

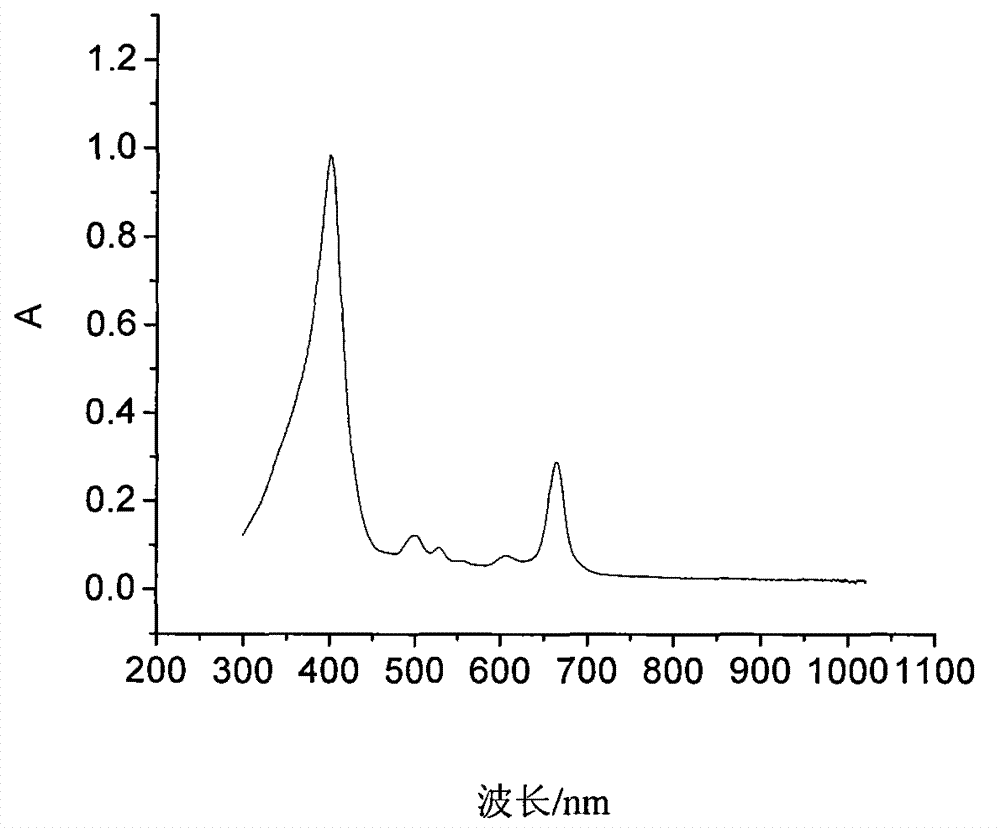

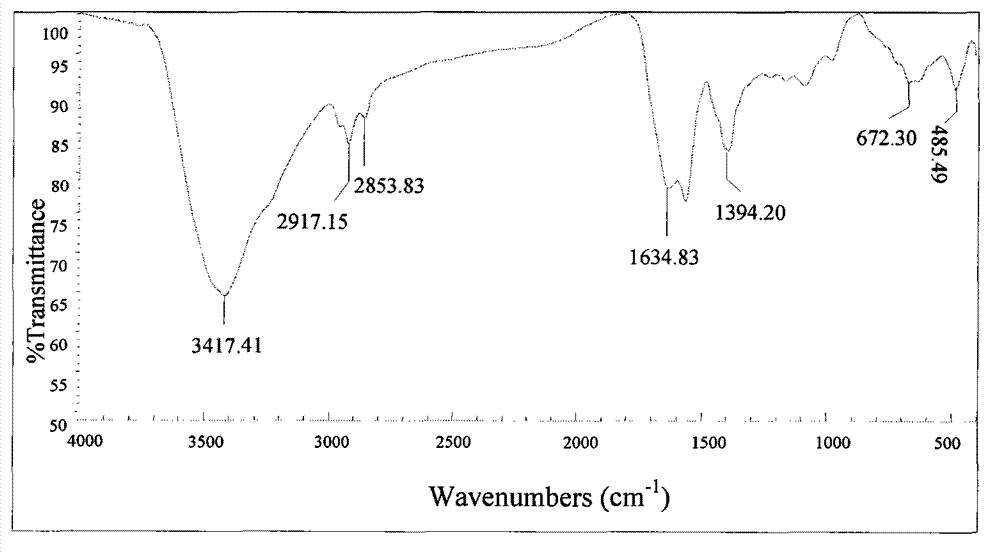

[0024] Sodium iron chlorophyllin is dissolved in water to make the solution concentration 0.67g / 100ml. Add the magnesium salt solution into the ferric chlorophyllin sodium salt solution, stir at a speed of 1000r / min, and make it fully react at room temperature. Aging at room temperature for 5h. Separation by filtration and drying at 60°C for 2 hours to obtain black (dark green) iron-magnesium chlorophyll. Carry out the measurement of each index. Wherein, by AVATAR360 type Fourier transform infrared spectrometer, UV7652 spectrophotometer, obtain chlorophyll iron sodium salt and chlorophyll iron magnesium salt spectrogram (see attached Figure 1~4 ), and analyzed and compared, it was determined that the product was chlorophyll iron-magnesium salt.

[0025] The calculated yield was 72%.

Embodiment 2

[0027] Sodium iron chlorophyllin is dissolved in water to make the solution concentration 0.67g / 100ml. Add the magnesium salt solution into the ferric chlorophyllin sodium salt solution, stir at a speed of 1000r / min, and make it fully react at room temperature. Aging at room temperature for 7h. Separation by filtration, and drying at 60°C for 2.5 hours to obtain black (dark green) chlorophyll iron-magnesium salt. Carry out the measurement of each index.

[0028] The calculated yield was 78%.

Embodiment 3

[0030] Sodium iron chlorophyll salt is dissolved in water with a solution concentration of 0.67g / 100ml. Add magnesium salt solution, stir at a speed of about 1000r / min, and make it fully react at room temperature. The aging time is 9h at room temperature. Separation by filtration, and drying at 60°C for 3 hours to obtain black (dark green) chlorophyll iron-magnesium salt. Carry out the measurement of each index.

[0031] The calculated yield was 74%.

[0032] Salt formation analysis of chlorophyll iron and magnesium:

[0033] 1. Judging from the changes in the experimental phenomena, after dissolving sodium iron chlorophyllin in water, the color of the solution is dark green. When adding a colorless magnesium salt solution, black precipitates are immediately produced, indicating that new substances are formed.

[0034] 2. Ultraviolet-visible absorption spectrum (UV) analysis

[0035] See attached figure 1 , 2 and the following table. From the analysis of the UV spectrum,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com