Fluoroacrylate pressure sensitive adhesive, and preparation method thereof

An acrylate and pressure-sensitive adhesive technology, applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of non-silicon transfer and proposed effective methods, so as to reduce the transfer of silicon, The carbon-fluorine bond can be large, and the effect of improving cohesion and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

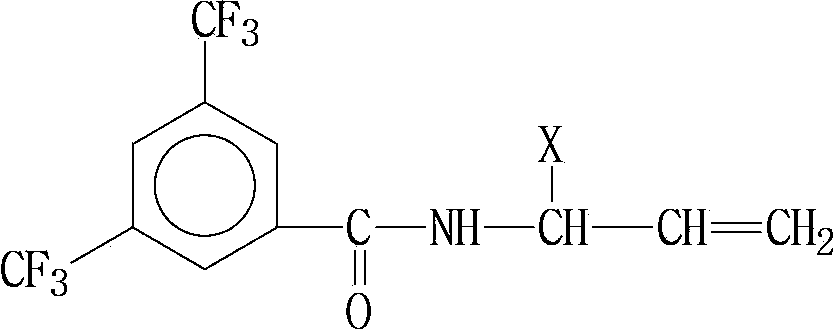

[0052] The preparation steps of fluorine-containing hard monomer are as follows:

[0053] Dissolve 3,5-bis(trifluoromethyl)benzoic acid in N,N-dimethylformamide, place in a reaction vessel and cool with ice water, add 1-hydroxybenzotriazole and K 2 CO 3 , and then add an equimolar amount of reaction monomer with 3,5-bis(trifluoromethyl)benzoic acid, stir at room temperature for 2~3 hours, add saturated NaHCO 3 Solution reaction, followed by extraction and recrystallization to obtain fluorine-containing hard monomers;

[0054] Among them, 1-hydroxybenzotriazole and K 2 CO 3 The molar mass ratio of 1-hydroxybenzotriazole to 3,5-bis(trifluoromethyl)benzoic acid is 1.5:1;

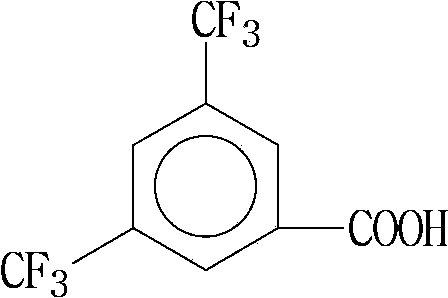

[0055] The molecular structural formula of the 3,5-bis(trifluoromethyl)benzoic acid is:

[0056]

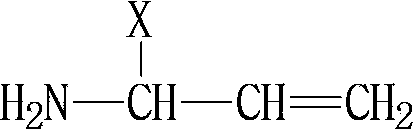

[0057] The structural characteristics of the described reaction monomer are:

[0058]

[0059] Among them, X is an alkane group containing a hydroxyl group.

[0060] A preparation method of fluorine-c...

Embodiment 2

[0063] The preparation steps of fluorine-containing hard monomer are as follows:

[0064] Dissolve 3,5-bis(trifluoromethyl)benzoic acid in N,N-dimethylformamide, place in a reaction vessel and cool with ice water, add 1-hydroxybenzotriazole and K 2 CO 3 , and then add an equimolar amount of reaction monomer with 3,5-bis(trifluoromethyl)benzoic acid, stir at room temperature for 2~3 hours, add saturated NaHCO 3 Solution reaction, followed by extraction and recrystallization to obtain fluorine-containing hard monomers;

[0065] Among them, 1-hydroxybenzotriazole and K 2 CO 3 The molar mass ratio of 1-hydroxybenzotriazole to 3,5-bis(trifluoromethyl)benzoic acid is 2:1;

[0066] The molecular structural formula of the 3,5-bis(trifluoromethyl)benzoic acid is:

[0067]

[0068] The structural characteristics of the described reaction monomer are:

[0069]

[0070] Among them, X is an alkane group containing a hydroxyl group.

[0071] A preparation method of fluorine-con...

Embodiment 3

[0074] The preparation steps of fluorine-containing hard monomer are as follows:

[0075] Dissolve 3,5-bis(trifluoromethyl)benzoic acid in N,N-dimethylformamide, place in a reaction vessel and cool with ice water, add 1-hydroxybenzotriazole and K 2 CO 3 , and then add an equimolar amount of reaction monomer with 3,5-bis(trifluoromethyl)benzoic acid, stir at room temperature for 2~3 hours, add saturated NaHCO 3 Solution reaction, followed by extraction and recrystallization to obtain fluorine-containing hard monomers;

[0076] Among them, 1-hydroxybenzotriazole and K 2 CO 3 The molar mass ratio of 1-hydroxybenzotriazole to 3,5-bis(trifluoromethyl)benzoic acid is 1.75:1;

[0077] The molecular structural formula of the 3,5-bis(trifluoromethyl)benzoic acid is:

[0078]

[0079] The structural characteristics of the described reaction monomer are:

[0080]

[0081] Among them, X is an alkane group containing a hydroxyl group.

[0082] A preparation method of fluorine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com