Preparation method of hydroxyl gallium oxide nanometer crystal

A gallium oxyhydroxide, nanocrystal technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of limiting the synthesis size and morphology of GaOOH crystals, the lack of efficient progress of GaOOH, and harsh conditions. , to achieve the effect of low cost, simple process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

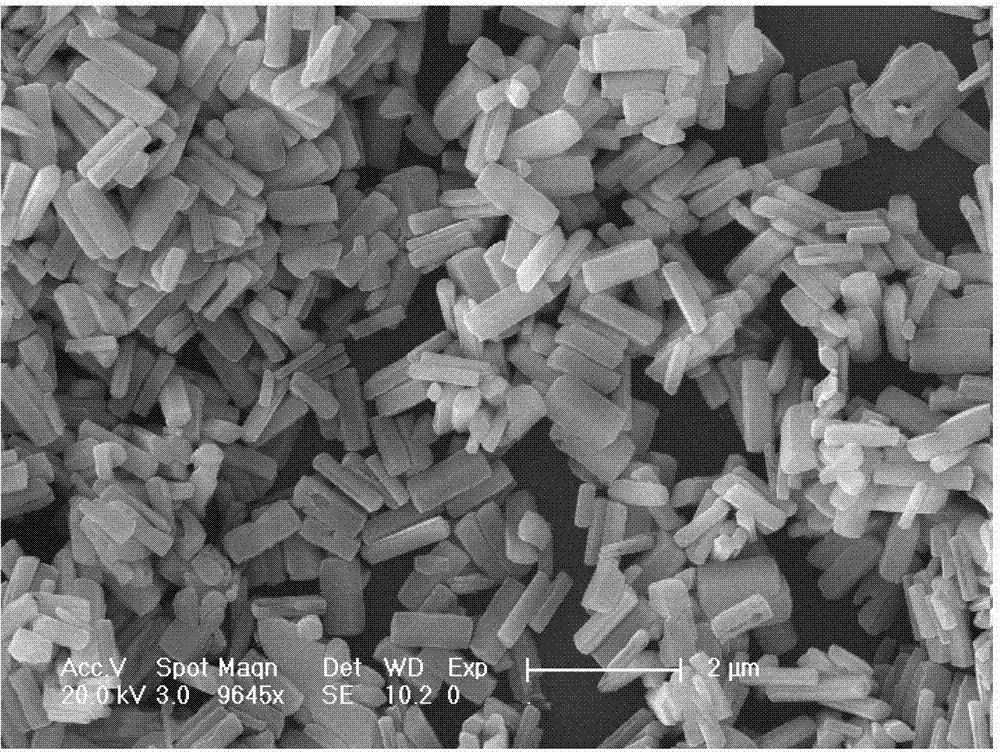

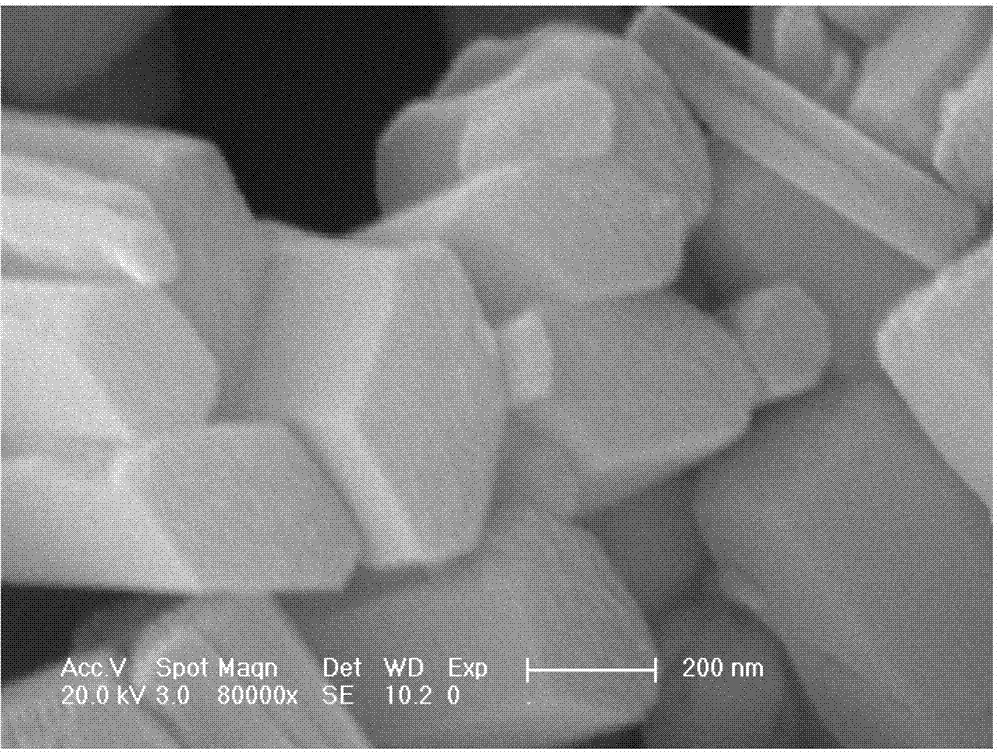

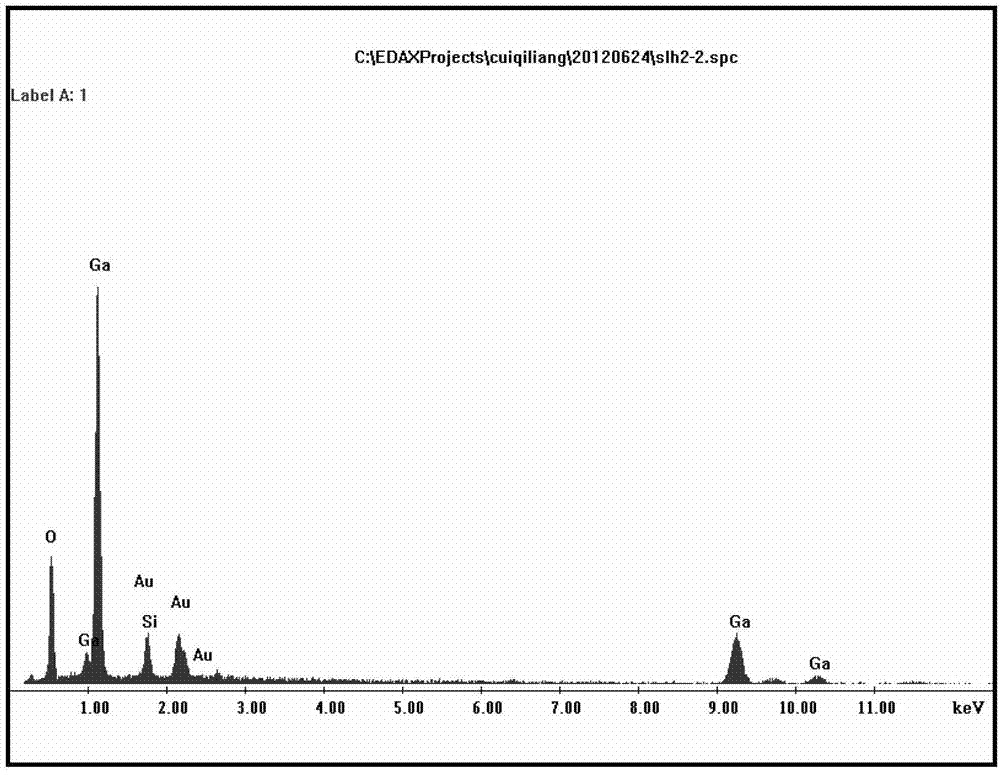

[0032] Example 1 The best overall process for preparing GaOOH nano-hexagonal prisms.

[0033] Using high-purity gallium chloride, benzene, CTAB and deionized aqueous solution as raw materials, first dissolve gallium chloride in benzene to prepare a benzene saturated solution of gallium chloride; dissolve 0.0546g CTAB in 30ml of deionized water to prepare 5mmol / L CTAB aqueous solution. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance into a clean beaker, and dilute it to 15ml with benzene. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonic treatment, and the prepared 5 mmol / L CTAB aqueous solution was dripped dropwise with a syringe during the ultrasonic treatment. When the upper layer of benzene solution is brown and the lower layer of aqueous solution is colorless and transparent and does not change any more, take out the beaker, pour the liquid in the beaker into a self-made polytetrafluoroeth...

Embodiment 2

[0036] Example 2 The whole process of preparing GaOOH nanocrystals.

[0037] Using high-purity gallium chloride, benzene, CTAB and deionized aqueous solution as raw materials, first dissolve gallium chloride in benzene to prepare a benzene saturated solution of gallium chloride; dissolve 0.1092g CTAB in 30ml of deionized water to prepare 10mmol / L CTAB aqueous solution. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance into a clean beaker, and dilute it to 16.5ml with benzene. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonication, and the prepared 10 mmol / L CTAB aqueous solution was dripped dropwise with a syringe during the ultrasonication process. When the benzene solution in the upper layer is brown and the aqueous solution in the lower layer is colorless and transparent and does not change any more, take out the beaker, pour the liquid in the beaker into a self-made polytetrafluoro reactor a...

Embodiment 3

[0039] Example 3 The whole process of preparing GaOOH nanocrystals.

[0040] Using high-purity gallium chloride, benzene, CTAB and deionized aqueous solution as raw materials, first dissolve gallium chloride in benzene to prepare a benzene saturated solution of gallium chloride; dissolve 1.092g CTAB in 30ml of deionized water to prepare 100mmol / L CTAB aqueous solution. Use a pipette to measure 1.5ml of the benzene saturated solution of gallium chloride prepared in advance into a clean beaker, and dilute it to 15ml with benzene. Afterwards, the beaker was placed in an ultrasonic instrument for ultrasonication, and the prepared 100 mmol / L CTAB aqueous solution was dripped dropwise with a syringe during the ultrasonication process. When the benzene solution in the upper layer is brown and the aqueous solution in the lower layer is colorless and transparent and does not change any more, take out the beaker, pour the liquid in the beaker into a self-made polytetrafluoro reactor an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com