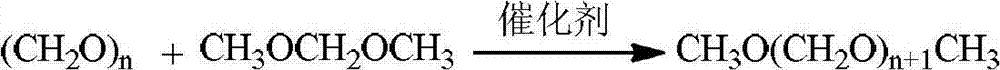

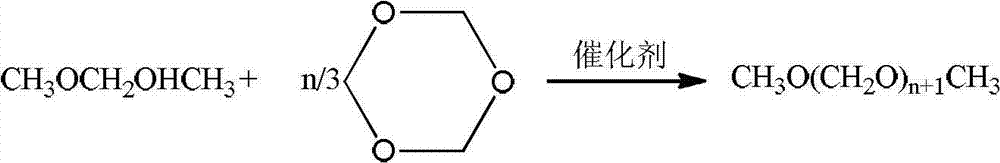

Method for preparation of polyoxymethylene dimethyl ethers through catalysis of pyrrolidone ionic liquid

A polyoxymethylene dimethyl ether, catalytic preparation technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of complex preparation process and low catalyst activity, and achieve simple reaction process and high catalytic activity. , easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a 100ml autoclave, add 6.0wt% catalyst a, 15.98g paraformaldehyde, and 7.54g methylal in sequence. Inflate nitrogen to a pressure of 3 MPa, slowly heat to 140°C and stir for 4 hours, after cooling and standing still, the product is analyzed by gas chromatography, and its composition distribution is as follows (expressed in weight %): methylal, 41.6%; n=2, 26.7%; n=3, 12.7%; n=4, 5.9%; n=5~8, 11.9%, n>8, margin.

Embodiment 2

[0037] In a 100ml autoclave, 10.0wt% catalyst b, 13.96g paraformaldehyde, and 31.71g methylal were sequentially added. Inflate nitrogen gas to a pressure of 3.5 MPa, slowly heat to 95°C and stir for 7 hours, after cooling and standing still, the product is analyzed by gas chromatography, and its composition distribution is as follows (expressed in weight %): methylal, 36.8%; n=2, 27.6% ; n=3, 13.6%; n=4, 6.8%; n=5~8, 13.8%, n>8, margin.

Embodiment 3

[0039] In a 100ml autoclave, add 5.0wt% catalyst c, 6.03g paraformaldehyde, and 12.08g methylal in sequence. Inflate nitrogen to a pressure of 1 MPa, slowly heat to 110°C and stir for 6 hours, after cooling and standing still, the product is analyzed by gas chromatography, and its composition distribution is as follows (expressed in weight %): methylal, 31.8%; n=2, 29.9%; n=3, 15.6%; n=4, 7.7%; n=5~8, 14.2%, n>8, margin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com