Method for removing heavy metal in marine animal protein enzymed liquid

A proteolysis solution and marine animal technology, applied in the field of removing heavy metals in marine animal proteolysis solution, can solve problems such as not suitable for large-scale use, complicated operation process, loss of nutrients, etc., achieve low investment and operation costs, and simple process operation , the effect of small loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

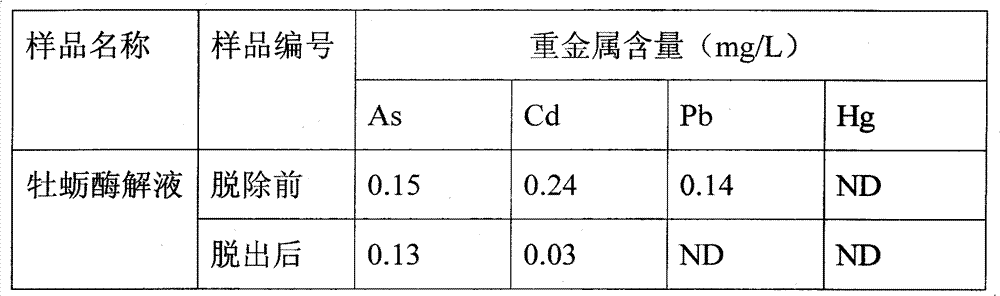

Embodiment 1

[0027] After shelling the oysters and taking the meat, add 2 times the volume of deionized water to homogenize for 5 minutes, sonicate for 10 minutes, then add neutral protease, the amount of enzyme added is 3000U / g, the enzymatic hydrolysis condition is pH=7, the enzymatic hydrolysis time is 4 hours, and the enzymatic hydrolysis The temperature is 50°C. After the reaction, inactivate the enzyme at 100°C for 10 minutes, centrifuge at high speed for 15 minutes, and add 3.0‰ (W 柠檬酸 / W 蛋白酶解液 ) was mixed with citric acid, the temperature was adjusted at 60°C, the reaction time was 20min, and the supernatant was obtained by centrifugation; the supernatant was adjusted to pass through D401 at a reaction temperature of 50°C, a pH of 6, and a column flow rate of 5 BV / h. Porous chelating resin column is used to remove heavy metals, and the enzymatic hydrolysis solution for removing harmful substances is obtained. The heavy metal content of the enzymatic solution before and after remov...

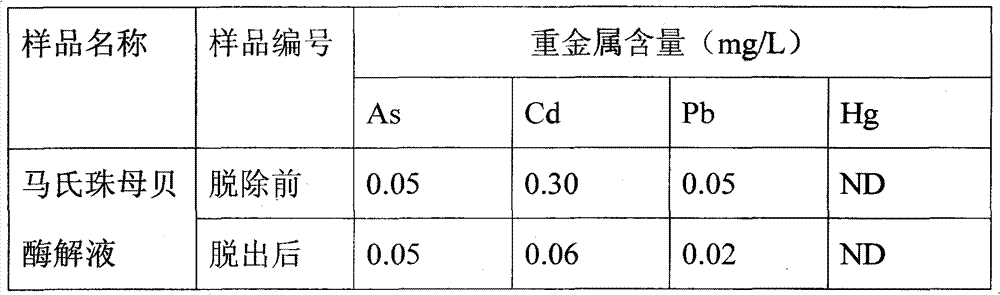

Embodiment 2

[0034] Remove the shell from Pinctada martensii and add 2 times the volume of deionized water to homogenize for 5 minutes, sonicate for 10 minutes, then add flavor protease, the amount of enzyme added is 7200U / g, the enzymatic hydrolysis condition is pH=7, and the enzymatic hydrolysis time is 5h , the enzymatic hydrolysis temperature is 60°C, after the reaction, the enzyme is extinguished at 100°C for 10 minutes, centrifuged at high speed for 15 minutes, and after filtering, add 3.0‰ (W 柠檬酸 / W 蛋白酶解液 ) was mixed with citric acid, the temperature was adjusted at 60°C, the reaction time was 20min, and the supernatant was obtained by centrifugation; the supernatant was adjusted to pass through D401 at a reaction temperature of 50°C, a pH of 5.5, and a column flow rate of 5 BV / h. Porous chelating resin column is used to remove heavy metals, and the enzymatic hydrolysis solution for removing harmful substances is obtained. The heavy metal content of the enzymatic solution before an...

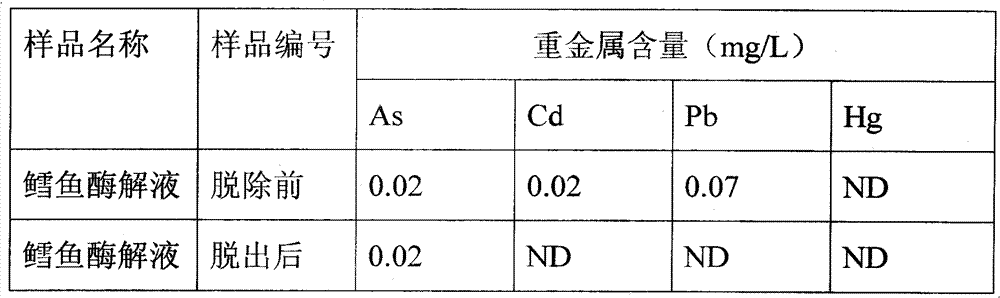

Embodiment 3

[0041] Remove the internal organs of the cod and take the meat, add 3 times deionized water to homogenate for 5 minutes, sonicate for 10 minutes, first add neutral protease for enzymatic hydrolysis, the amount of enzyme added is 3000U / g, the enzymatic hydrolysis condition is pH 7, and the enzymatic hydrolysis time is 3 hours, and then the Adjust the pH to 9, add alkaline protease for enzymolysis, the amount of enzyme added is 800U / g, the enzymolysis time is 3h, and the enzymolysis temperature is kept at 55°C. After the reaction is completed, the enzyme is extinguished at 100°C for 10min, high-speed centrifugation for 15min, and filtered in the proteolysis solution Add 1.0‰(W 柠檬酸 / W 蛋白酶解液 ) mixed with citric acid, the temperature was adjusted at 50°C, the reaction time was 15min, and the supernatant was centrifuged; the supernatant was adjusted to pass through the ion exchange resin at a reaction temperature of 50°C, a pH of 6, and a column flow rate of 15BV / h. The column is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com