Modified nylon material and its preparation method

A technology for modifying nylon and nylon is applied in the field of polymer modified materials, which can solve the problems of unreported research and development of pulling force, and achieve the effects of convenient production, simple process and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

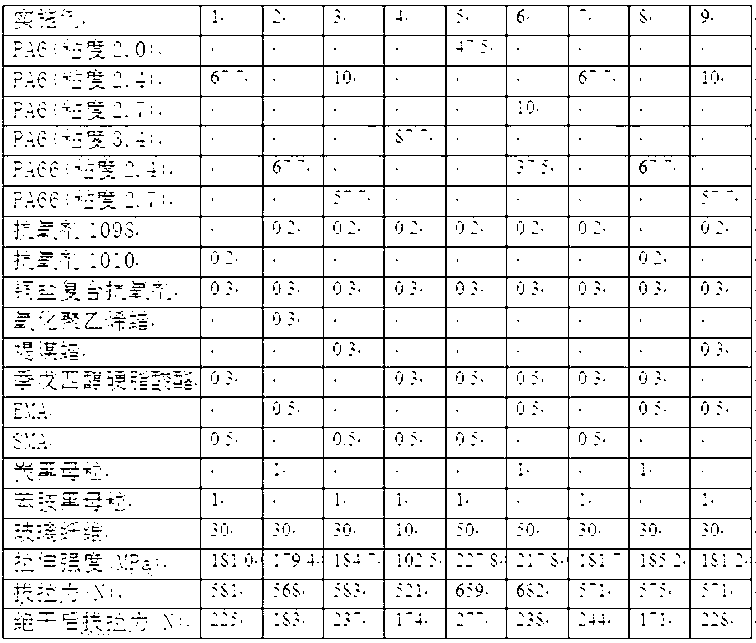

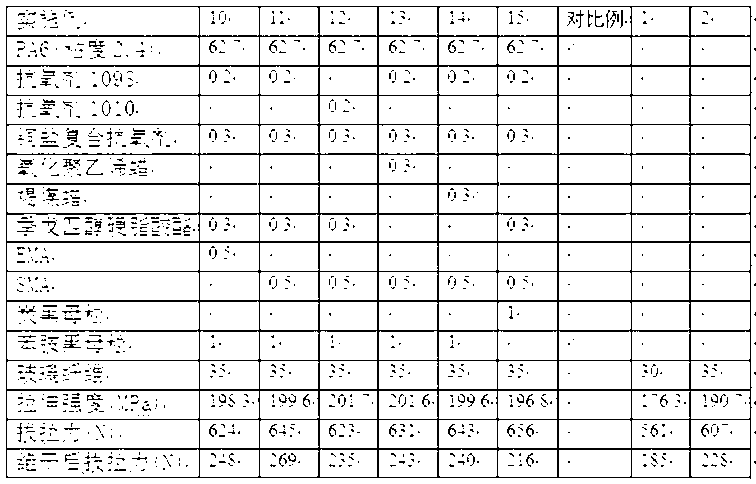

Embodiment 1

[0034] With 67.7 parts by weight of nylon 6 (viscosity 2.4), 0.2 parts by weight of antioxidant 1010, 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of pentaerythritol stearate, 0.5 parts by weight of SMA, 1 part by weight of nigrosine masterbatch Add it into the high-mixer, mix it evenly at room temperature, and then pass it into the extruder through the main feed port of the twin-screw extruder, and extrude 30 parts by weight of glass fiber surface-treated with an aminosilane coupling agent. The side feed port of the machine is connected to the extruder; the twin-screw extruder is used for extrusion granulation, the extrusion processing temperature is 210-260°C, and the main engine speed is 350 rpm. The extruded and granulated materials are cooled and dried to obtain nylon material products with high metal insert pull-out force.

Embodiment 2

[0036] Add 67.7 parts by weight of nylon 66 (viscosity 2.4), 0.2 parts by weight of antioxidant 1098, 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of oxidized polyethylene wax, 0.5 parts by weight of EMA, and 1 part by weight of carbon black masterbatch In the high-mixer, mix evenly at room temperature, and then pass into the extruder through the main feed port of the twin-screw extruder, and extrude 30 parts by weight of glass fiber surface-treated with aminosilane coupling agent through twin-screw extruder The side feed port of the extruder leads into the extruder; the twin-screw extruder is used for extrusion granulation, the extrusion processing temperature is 240-300°C, and the main engine speed is 350 rpm. The extruded and granulated materials are cooled and dried to obtain nylon material products with high metal insert pull-out force.

Embodiment 3

[0038] 57.7 parts by weight of nylon 66 (viscosity 2.7), 10 parts by weight of nylon 6 (viscosity 2.4), 0.2 parts by weight of antioxidant 1098, 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of montan wax, 0.5 parts by weight of SMA, Add 1 weight of nigrosine masterbatch into the high mixer, mix evenly at room temperature, and then pass it into the extruder through the main feed port of the twin-screw extruder, and add 30 parts by weight of aminosilane coupling agent surface-treated The glass fiber is fed into the extruder through the side feed port of the twin-screw extruder; the twin-screw extruder is used for extrusion and granulation, the extrusion processing temperature is 240-300°C, and the host speed is 350 rpm. The extruded and granulated materials are cooled and dried to obtain nylon material products with high metal insert pull-out force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com