Trichoderma koningiopsis strain and application of trichoderma koningiopsis to preparation of cellulase

A technology of cellulase and Trichoderma, applied in the direction of enzymes, enzymes, fungi, etc., can solve the problems of inability to hydrolyze and low activity level of β-glucosidase, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

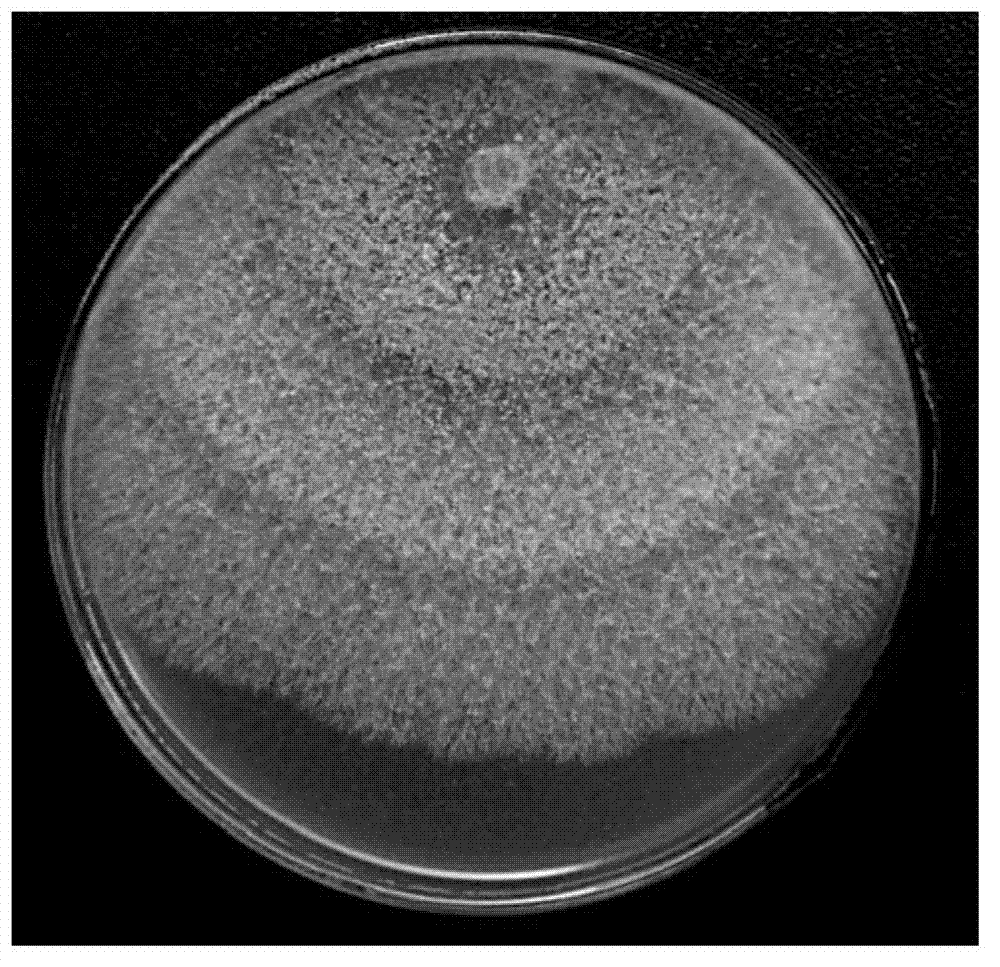

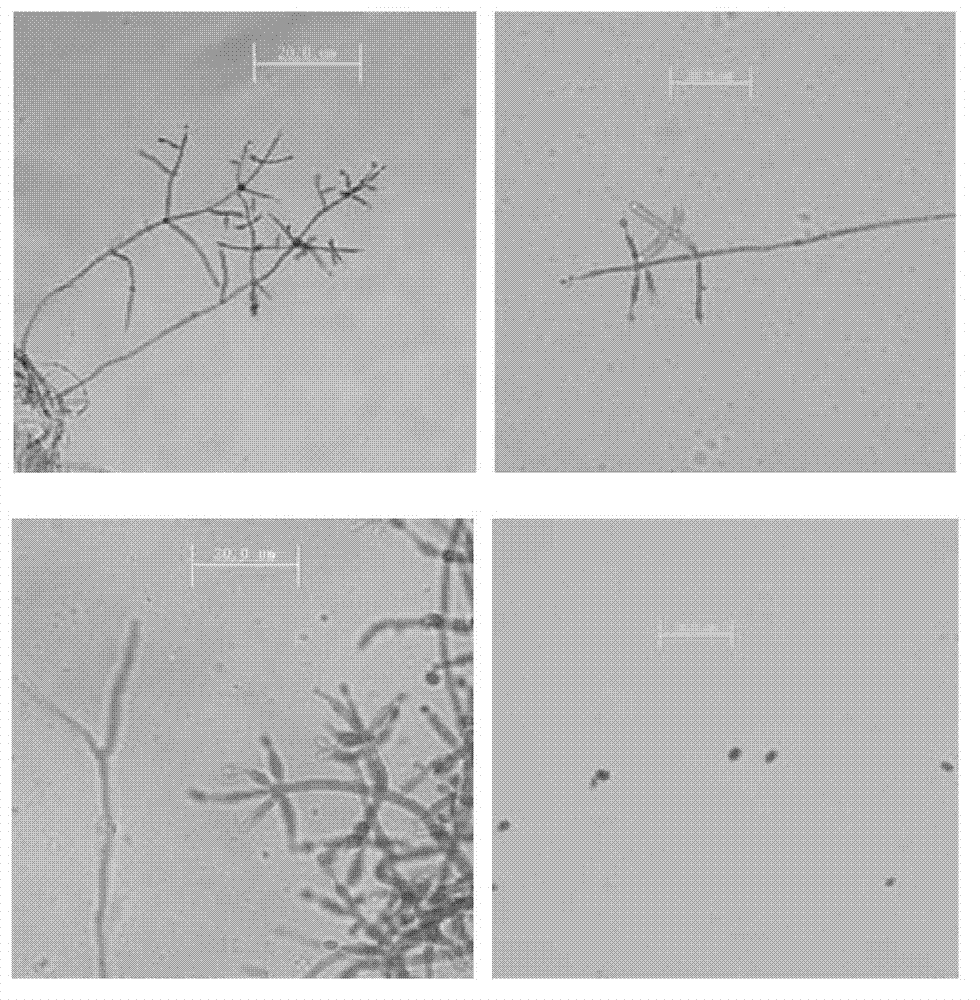

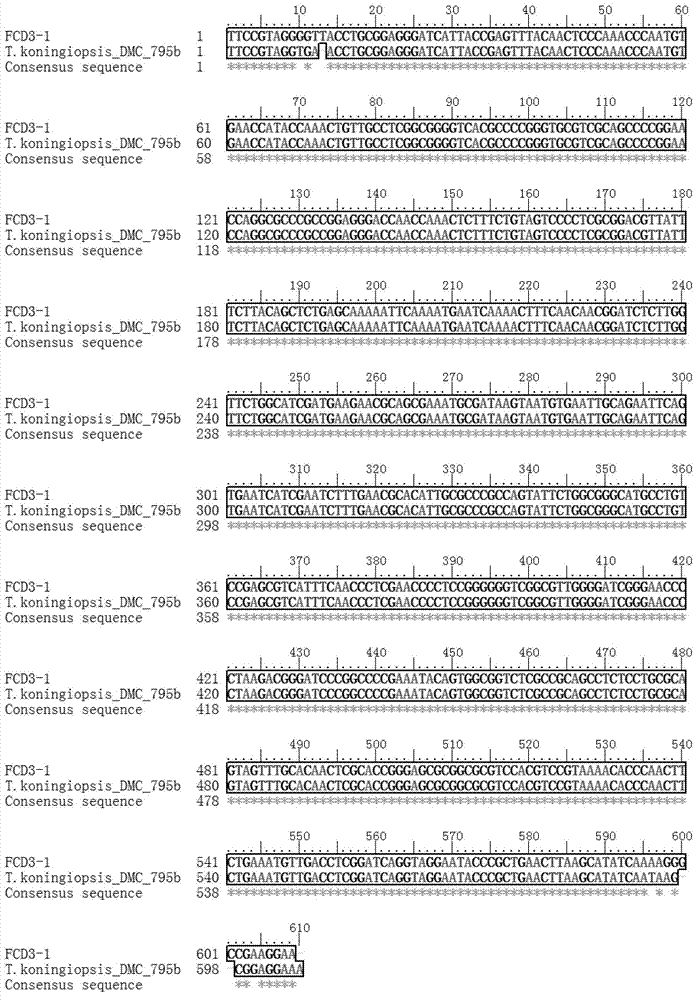

[0050] Example 1. Isolation and identification of Trichoderma strain FCD3-1

[0051] 1. Obtaining strains

[0052] 1. Collection of soil samples

[0053] It was collected near a starch factory in Fangchenggang City, Guangxi, China in March 2009; the surface cover soil was removed, and 50 grams of soil about 5-20 cm below the surface was taken as a sample; a total of 13 samples were collected scattered.

[0054] 2. Isolation and screening of cellulase-producing strains

[0055] (1) Prepare separation medium with deionized water; each liter of separation medium contains: KH 2 PO 4 2.0g, (NH 4 ) 2 SO 4 1.4g, urea 0.3g, MgSO 4 ·7H 2 O 0.3g, CaCl 2 0.3g, FeSO 4 ·7H 2 O 5.0mg, MnSO 4 ·H 2 O 1.56mg, ZnSO 4 ·7H 2 O 1.4mg, CoCl 2 2.0mg, Avicel (Sigma PH101) 10g, agar 15g; pH5.0; sterilized by moist heat at 121°C for 20min; after sterilization, the plate is poured when cooled to 50°C.

[0056] (2) Take 10g of soil sample into a 250ml Erlenmeyer flask, add 90ml of sterile water and add appropri...

Embodiment 2

[0066] Example 2: Preparation of cellulase using Trichoderma strain FCD3-1

[0067] 1. Obtaining fermentation broth

[0068] 1. Prepare basic medium (liquid) with pH 5.0

[0069] 2. Preparation of spore liquid

[0070] (1) Sterilize the PDA medium (solid) at 121°C for 20 minutes.

[0071] (2) The spores of Trichoderma FCD3-1 obtained in Example 1 were washed with sterile water and made into a spore suspension, the spore concentration was 1×10. 10 Pcs / ml.

[0072] 3. Obtaining fermentation broth

[0073] (1) Take 100ml of basic medium and put it in a 500ml Erlenmeyer flask.

[0074] (2) Take the spore liquid of Trichoderma FCD3-1 and inoculate it into the minimal medium at a rate of 1% (volume percentage), culture at 28°C and 180 rpm for 5 days, and collect the culture.

[0075] (3) Centrifuge (4°C, centrifugal radius 7cm, 12000rpm, centrifugation for 5min) to remove the bacteria, and collect the supernatant to obtain the Trichoderma FCD3-1 fermentation broth.

[0076] 2. Cellulase enzymatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com