Method of preparing porous graphene film by using electrostatic spray process

A technology of porous graphene and electrostatic spraying, applied in spinning solution preparation, textile and paper making, fiber treatment, etc., can solve the problems of complex process, low yield, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

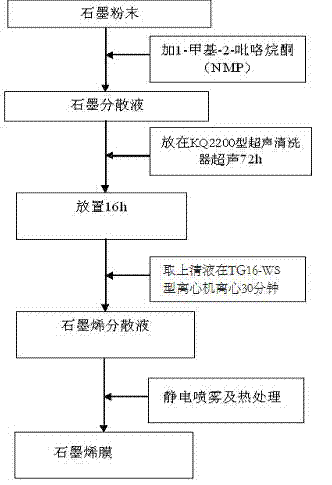

[0030] The process and steps of preparing porous graphene film are as follows:

[0031] Soak and clean the silicon wafers containing the surface oxide layer in ethyl acetate and acetone for 30 min, then ultrasonically clean the cleaned silicon wafers in ethanol and distilled water, and finally bake them with an infrared lamp.

[0032] Weigh 2.5 g of graphite powder (99.85%) and place it in a 250ml beaker, add 100ml of 1-methyl-2-pyrrolidone (NMP) to prepare graphite-NMP suspension for later use. Then the above suspension was sealed with multi-layer plastic wrap, and subjected to discontinuous ultrasonic treatment with a low-power ultrasonic cleaner at room temperature for a total of 72 h to obtain a graphene dispersion. Finally, after standing still for 16 h, the dispersion was centrifuged (8000 r / min) for 30 min, and the upper layer liquid was absorbed into a clean glass bottle for later use.

[0033] Pipette 10 ml of graphene dispersion into a 20 ml syringe, fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com