Heterogeneous scleral piece used for posterior scleral reinforcement and preparation method thereof

A technology of posterior scleral reinforcement and scleral lens, applied in the fields of tissue engineering and materials science, can solve the problems of slow development of posterior scleral reinforcement surgery, different quality standards of posterior scleral lens, inability to popularize and apply on a large scale, etc. Flip, good compliance, suitable hardness and elasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of heterogeneous sclera lens for posterior sclera reinforcement

[0031] 1 Materials and sources

[0032] The pericardium of slaughtered cattle is taken as the base material, and the cattle are quarantine-free and disease-free, and aseptic operation should be paid attention to in the process of material collection and transportation.

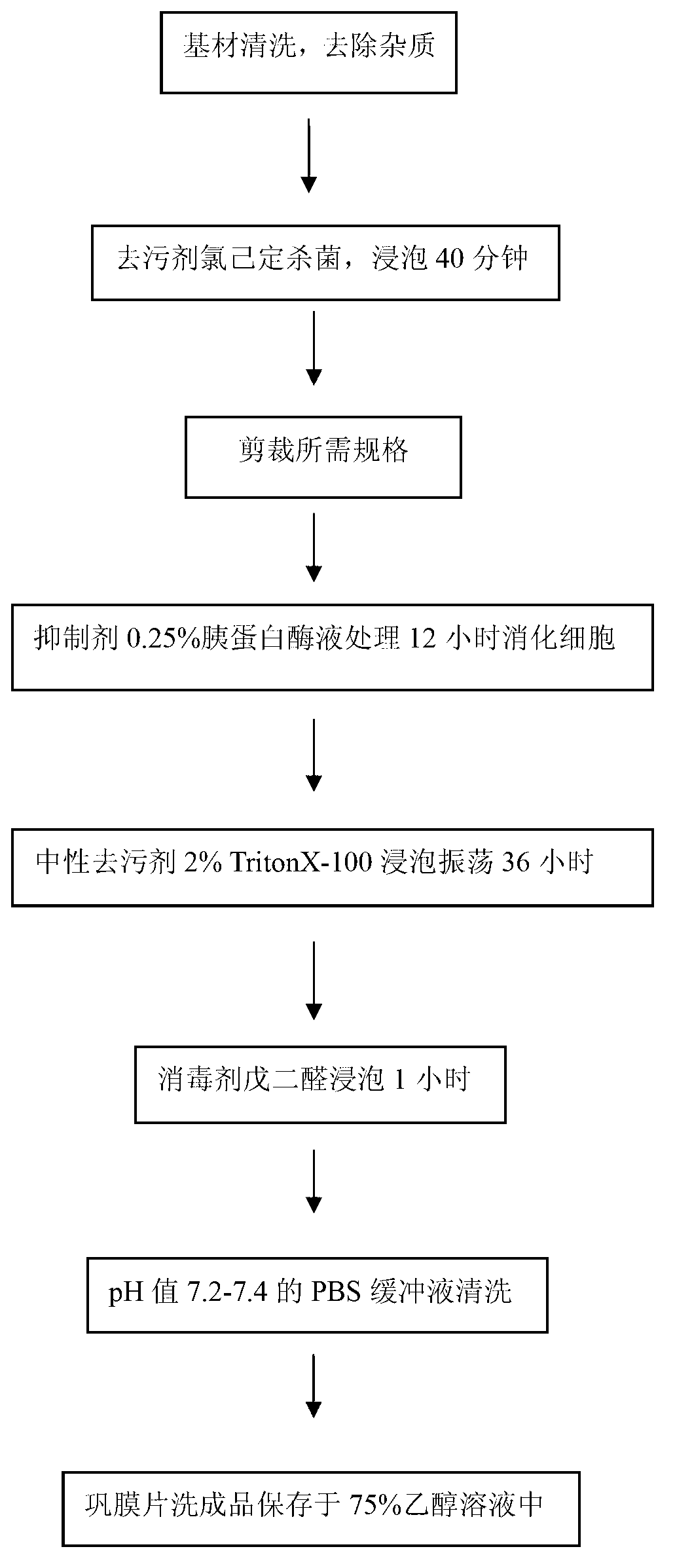

[0033] 2 Preparation of scleral lenses for posterior scleral reinforcement (see figure 1 )

[0034] 2.1 Base material pretreatment: remove impurities and excess parts (such as adipose tissue) on the pericardium, soak in distilled water, and disintegrate blood cells; then soak the base material in detergent chlorhexidine for 40 minutes to remove impurities and make Wool.

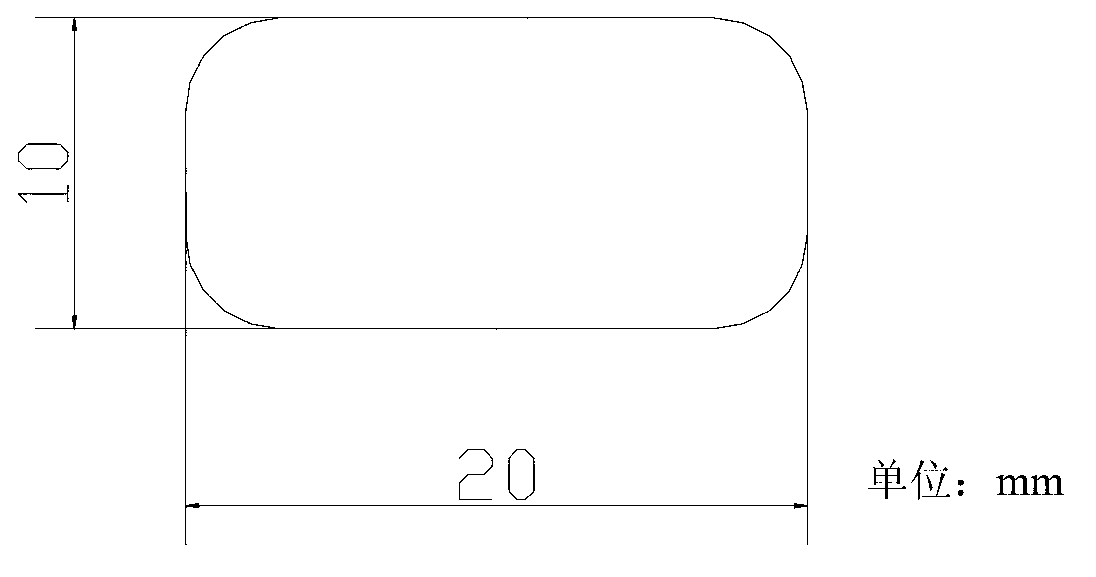

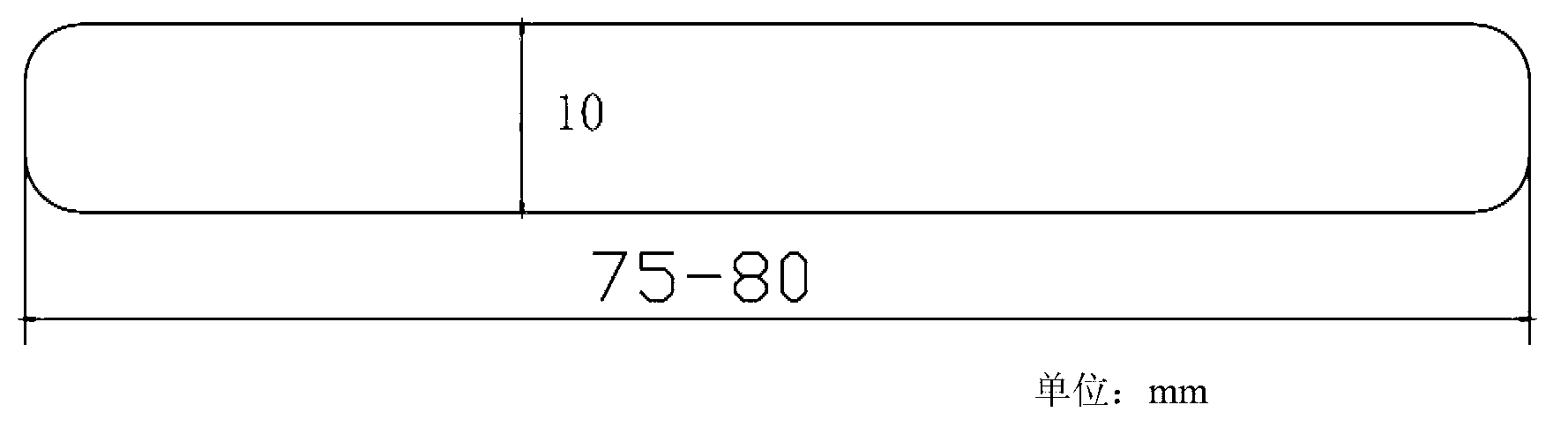

[0035] 2.2 Cutting and forming: Remove the part of the wool material with uneven thickness, elasticity, hardness and color after the treatment in 2.1, select the part with a thickness of 0.6-1mm, and cut or cut the wool material into shapes of di...

Embodiment 2

[0045] Example 2 Study on the biomechanical properties of the scleral lens after heterogeneous posterior sclera reinforcement

[0046] 1 Materials and preparation

[0047] The bovine pericardial patch, porcine pericardial patch and rabbit scleral patch were respectively used as base materials, and the corresponding posterior scleral patch was prepared according to the preparation process of Example 1.

[0048] 2. Biomechanical Research of Posterior Sclera of Different Materials In this example, the thickness of the posterior sclera was measured with a micro-thickness gauge to obtain the cross-sectional area of the posterior sclera. The mechanical properties of the posterior scleral lens can be measured by applying different tensions to the posterior scleral lens with a universal tensile machine.

[0049]In the mechanical observation of animal experiments on bovine pericardium, pig pericardium, and rabbit sclera, rabbits were selected as the experimental objects. The poster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com