Production technology of environment-friendly medium-density fiberboard

A production process and medium density technology, which is applied in the pretreatment of molding materials, manufacturing tools, adhesive types, etc., can solve the problem that the formaldehyde emission of the finished board does not meet the standard requirements, the difficulty of controlling the formaldehyde emission of the finished board increases, The addition ratio is difficult to achieve stability and other problems, so as to improve the heat transfer performance of the plate, reduce the release of free formaldehyde, and improve the density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

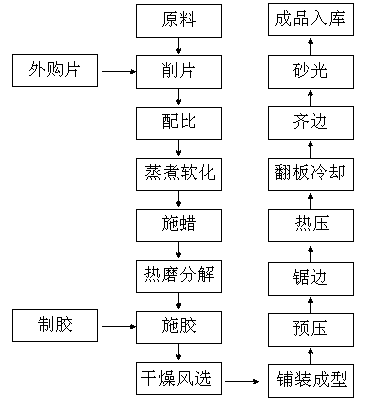

Method used

Image

Examples

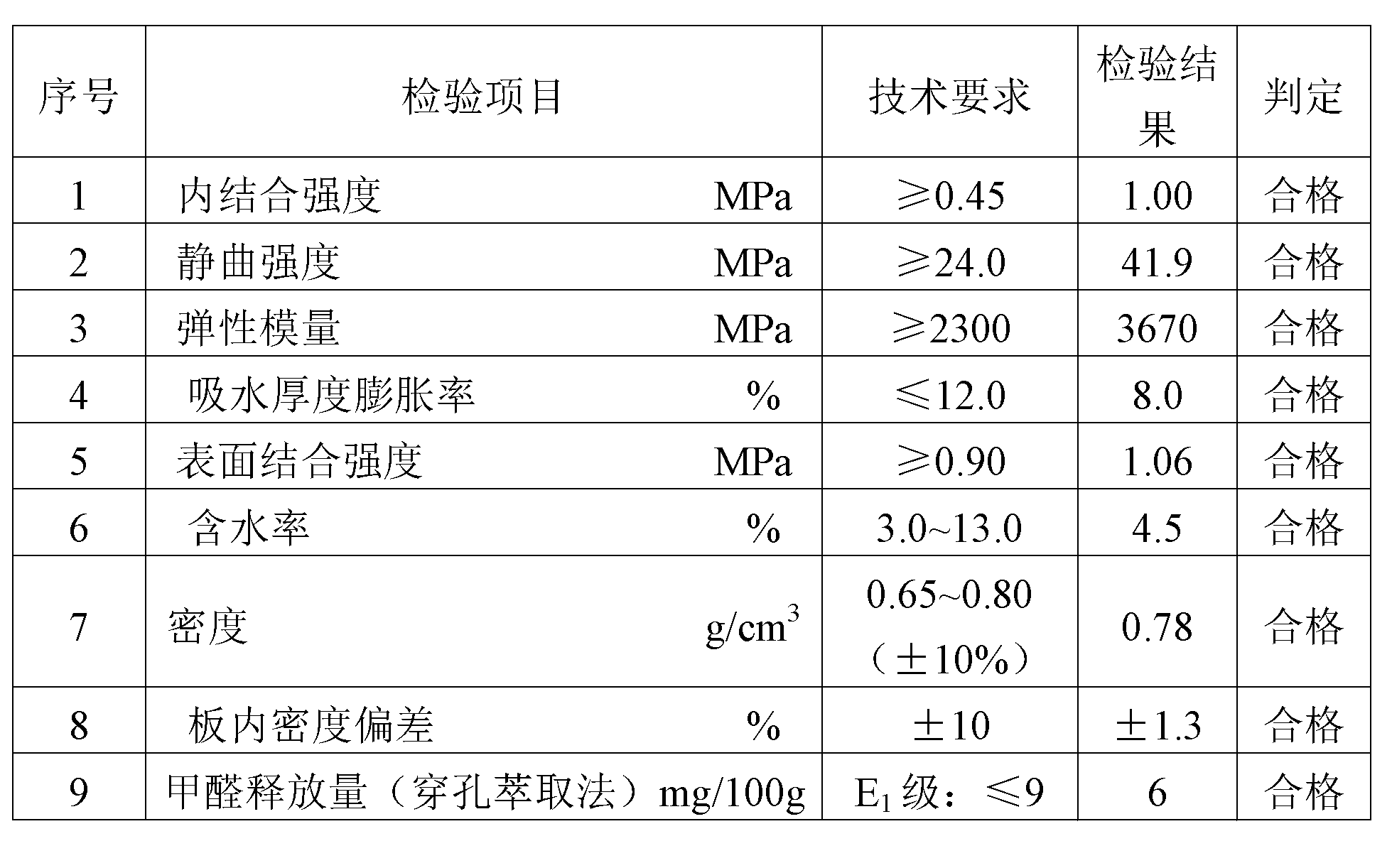

Embodiment 1

[0028] (1) Select the site for storing raw materials, control the moisture content of the selected raw materials at 40% to 60%, and classify and store the woody raw materials respectively.

[0029] (2) Chip various woody raw materials (such as small-diameter wood, wood processing residues, etc.) with a chipper. The wood chips are required to have a smooth cut and uniform size. 3~5mm. For purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0030] (3) Screen the flake raw materials, remove overly large wood chips and too small debris, and detect, adsorb and remove the possible iron metals in the raw materials.

[0031] (4) Evenly mix flake raw materials with different degrees of dryness and wetness, and then enter the steam buffer silo with a pressure of 0.6MPa and a temperature of 155°C after being treated by an oil-cooled electromagnetic separator for cooking and softening...

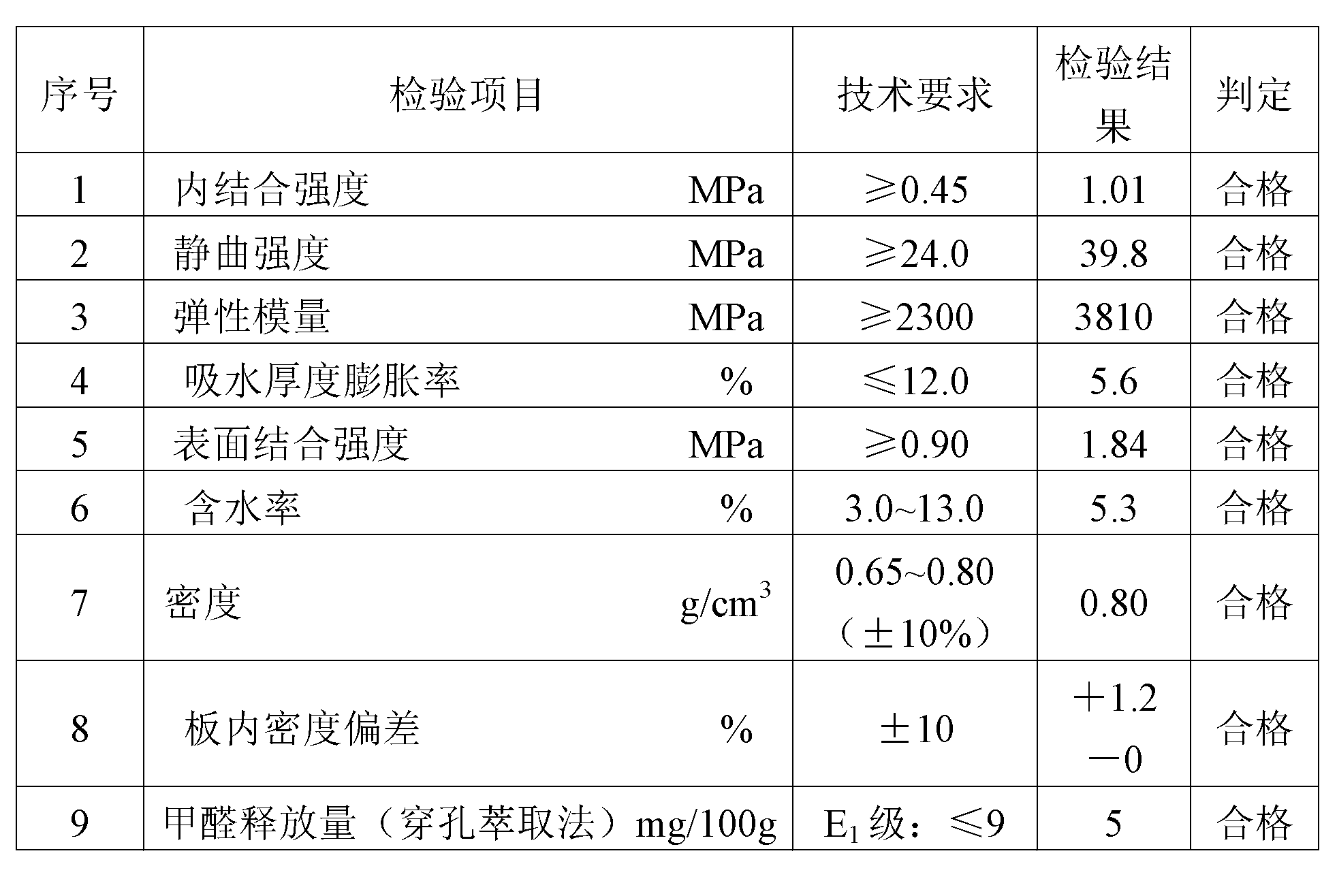

Embodiment 2

[0043] (1) Select the site for storing raw materials, control the moisture content of the selected raw materials at 40% to 60%, and classify and store the woody raw materials respectively.

[0044] (2) Chip various woody raw materials (such as small-diameter wood, wood processing residues, etc.) with a chipper. The wood chips are required to have a smooth cut and uniform size. 3~5mm. For purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0045] (3) Screen the flake raw materials, remove overly large wood chips and too small debris, and detect, adsorb and remove the possible iron metals in the raw materials.

[0046] (4) Evenly mix flake raw materials with different degrees of dryness and humidity, and then enter the steam buffer silo with a pressure of 0.8MPa and a temperature of 160°C after being treated by an oil-cooled electromagnetic separator for cooking and softening....

Embodiment 3

[0058] (1) Select the site for storing raw materials, control the moisture content of the selected raw materials at 40% to 60%, and classify and store the woody raw materials respectively.

[0059] (2) Chip various woody raw materials (such as small-diameter wood, wood processing residues, etc.) with a chipper. The wood chips are required to have a smooth cut and uniform size. 3~5mm. For purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0060] (3) Screen the flake raw materials, remove overly large wood chips and too small debris, and detect, adsorb and remove the possible iron metals in the raw materials.

[0061] (4) Evenly mix flake raw materials with different degrees of dryness and wetness, and then enter the steam buffer silo with a pressure of 1.0MPa and a temperature of 170°C after being treated by an oil-cooled electromagnetic separator for cooking and softening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com