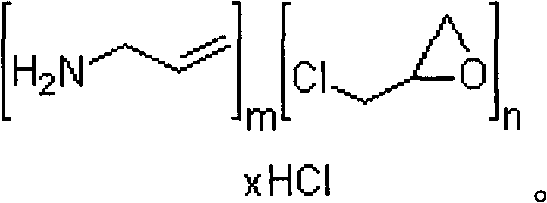

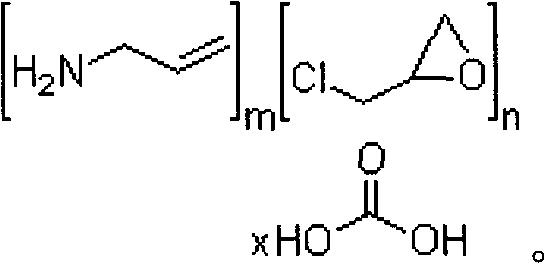

Method for preparing sevelamer carbonate

A technology of sevelamer carbonate and sevelamer hydrochloride, which is applied in the field of biomedicine, can solve the problems of high impurity content of sevelamer carbonate and the impact on the quality of sevelamer carbonate, so as to save reaction time and solvent, Strong anti-pollution ability and accelerated mass transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 300g of sevelamer hydrochloride granules to 2000ml of 5% sodium hydroxide solution. After stirring for 4 hours, add deionized water to wash until the pH value of the washing solution is nearly neutral to obtain alkaline sevelamer cation Resin.

[0051] Put 2000ml sulfonic acid cation exchange resin into an empty resin column with a height-to-diameter ratio of 10:1 after conventional pretreatment, add 600g sodium carbonate solution, and wash with water until the effluent aqueous solution is neutral. Ingredients are carbonate ions. The above aqueous solution is continuously added to the alkaline sevelamer cationic resin, washed with water, and circulated until the outflowing aqueous solution is neutral, and the cationic resin is collected to obtain sevelamer carbonate. Then sevelamer carbonate was added to the Soxhlet extraction reactor, 2L of isopropanol was added to extract impurities, and finally the residue in the Soxhlet extraction reactor was collected, washed wit...

Embodiment 2

[0053] Add 300g of sevelamer hydrochloride granules to 2000ml of 5% potassium hydroxide solution and stir for 4 hours to obtain an alkaline dispersion of sevelamer, and then pour the dispersion into a height-to-diameter ratio of 10:1 In the empty resin column, add deionized water to wash until the pH value of the eluent is nearly neutral, and then wash the resin with methanol until the weight content of water in the methanol is less than 0.3% to obtain the basic sevelamer cation Resin.

[0054] Load 2000ml of sulfonic acid cation exchange resin into an empty resin column with a height-to-diameter ratio of 10:1, add 600g of sodium carbonate solution and wash with water until the outflowing aqueous solution is neutral, and the main component of the aqueous solution is carbonate ion . The above aqueous solution is continuously added to the above alkaline sevelamer cation resin, the volume ratio of carbonate solution and alkaline sevelamer cation resin is 6:1, washing with water and...

Embodiment 3

[0056] This example is basically the same as Example 1, except that after adding sevelamer carbonate to the Soxhlet extraction reactor, 10 times the volume of sevelamer carbonate is added to extract impurities, and finally the Soxhlet extraction reaction is collected The residue in the vessel, the ether was removed, filtered, ground, and sieved to obtain 250 g of a white granular solid, namely: carbonate of Sevelamer, with a purity of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com